Graphene/polyimide composite membrane and preparation method thereof

A composite film and polyimide technology, applied in the field of graphene/polyimide composite film and its preparation, can solve the problems of poor mechanical properties and flexibility, low thermal conductivity of graphite film, etc., and achieve good bending resistance Performance, high thermal conductivity, good flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

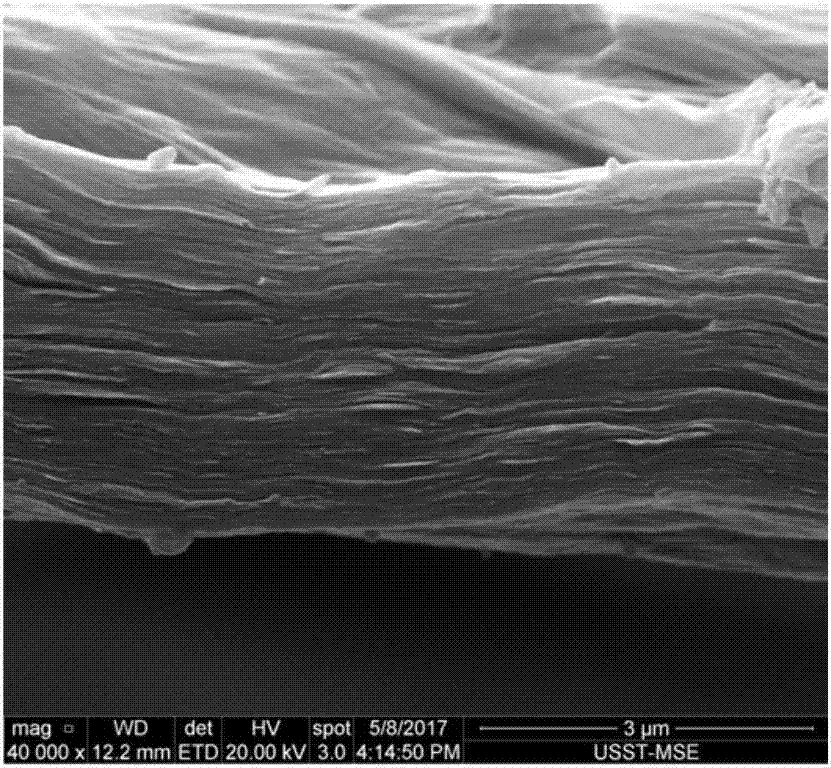

Image

Examples

Embodiment 1

[0051] A kind of preparation method of graphene / polyimide composite film specifically comprises steps as follows:

[0052] (1) Control the power to 300W and ultrasonicate for 10 minutes at a frequency of 40kHz to dissolve 4,4'-diaminodiphenyl ether and pyromellitic dianhydride in N,N-dimethylformamide respectively to obtain 4, 4'-diaminodiphenyl ether solution and pyromellitic dianhydride solution;

[0053] Then, add graphene oxide powder to the 4,4'-diaminodiphenyl ether solution and pyromellitic dianhydride solution obtained above, and then use 300W power and 40kHz ultrasonic wave for 30min to make the graphene oxide uniform dispersed in 4,4'-diaminodiphenyl ether solution and pyromellitic dianhydride solution to obtain graphene oxide / pyromellitic dianhydride mixed solution and graphene oxide / 4,4'-diamino diphenyl ether solution;

[0054] In the above graphene oxide / 4,4'-diaminodiphenyl ether solution, the amount of 4,4'-diaminodiphenyl ether, graphene oxide powder and N,N...

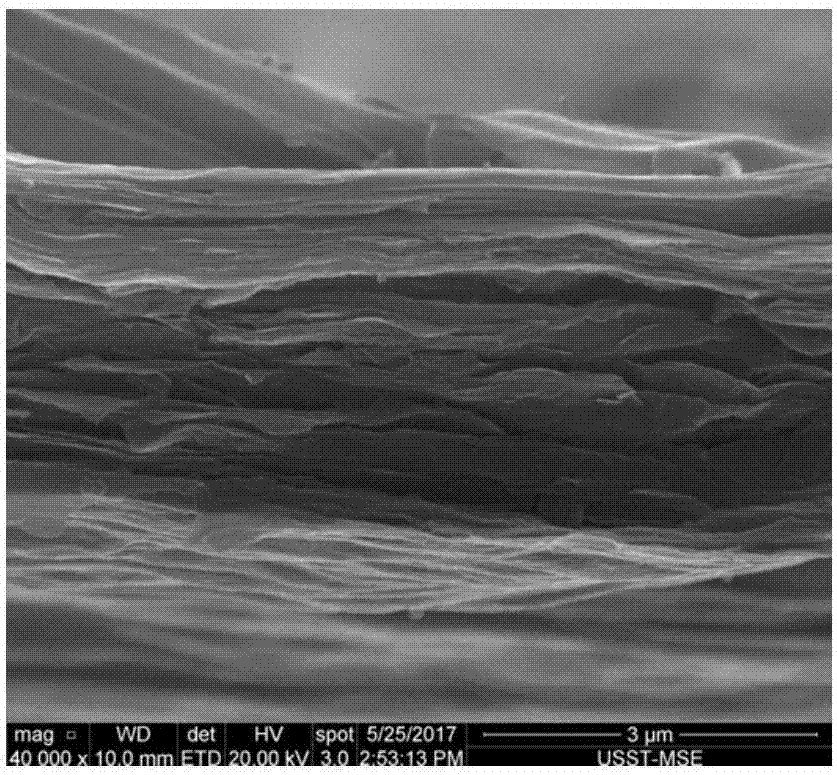

Embodiment 2

[0064] A kind of preparation method of graphene / polyimide composite film specifically comprises steps as follows:

[0065] (1) Control the power to 300W and ultrasonicate for 10 minutes at a frequency of 40kHz to dissolve 4,4'-diaminodiphenyl ether and pyromellitic dianhydride in N,N-dimethylformamide respectively to obtain 4, 4'-diaminodiphenyl ether solution and pyromellitic dianhydride solution;

[0066] Then, add graphene oxide powder to the 4,4'-diaminodiphenyl ether solution and pyromellitic dianhydride solution obtained above, and then use 300W power and 40kHz ultrasonic wave for 30min to make the graphene oxide uniform dispersed in 4,4'-diaminodiphenyl ether solution and pyromellitic dianhydride solution to obtain graphene oxide / pyromellitic dianhydride mixed solution and graphene oxide / 4,4'-diamino diphenyl ether solution;

[0067] In the above graphene oxide / 4,4'-diaminodiphenyl ether solution, the amount of 4,4'-diaminodiphenyl ether, graphene oxide powder and N,N...

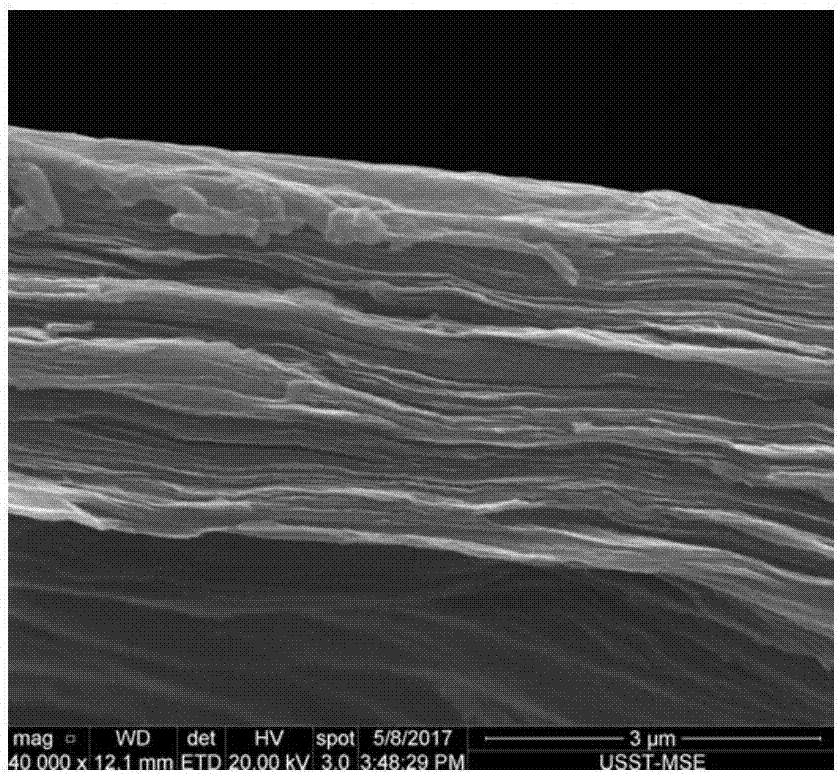

Embodiment 3

[0077] A kind of preparation method of graphene / polyimide composite film specifically comprises steps as follows:

[0078] (1) Control the power to 300W and ultrasonicate for 10 minutes at a frequency of 40kHz to dissolve 4,4'-diaminodiphenyl ether and pyromellitic dianhydride in N,N-dimethylformamide respectively to obtain 4, 4'-diaminodiphenyl ether solution and pyromellitic dianhydride solution;

[0079] Then, add graphene oxide powder to the 4,4'-diaminodiphenyl ether solution and pyromellitic dianhydride solution obtained above, and then use 300W power and 40kHz ultrasonic wave for 30min to make the graphene oxide uniform dispersed in 4,4'-diaminodiphenyl ether solution and pyromellitic dianhydride solution to obtain graphene oxide / pyromellitic dianhydride mixed solution and graphene oxide / 4,4'-diamino diphenyl ether solution;

[0080]In the above graphene oxide / 4,4'-diaminodiphenyl ether solution, the amount of 4,4'-diaminodiphenyl ether, graphene oxide powder and N,N-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com