Amino acid soap and preparation method thereof

An amino acid and acyl amino acid technology, applied in the field of daily necessities, can solve the problems of amino acid soap not durable, difficult to make square or special-shaped amino acid soap, inconvenient storage and transportation, etc., and achieve good cleaning ability and skin feeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The present invention provides a kind of preparation method of amino acid soap as described in above-mentioned technical scheme, comprises the steps:

[0064] A) mixing the N-acyl amino acid and the moisturizing agent, heating and stirring to obtain the first mixed solution;

[0065] Mixing and heating triethanolamine, arginine, and a strong base to obtain a second mixed solution;

[0066] B) mixing the first mixed solution with the second mixed solution, and then mixing with the skin feel regulator to obtain the third mixed solution;

[0067] C) Defoaming the third mixed solution, filling it into a mold to obtain amino acid soap.

[0068] In the present invention, the N-acyl amino acid and the moisturizing agent are firstly mixed, heated and stirred to obtain the first mixed solution.

[0069] The present invention has clearly described the specific components and proportions of the N-acyl amino acid and the moisturizing agent above, and will not repeat them here.

...

Embodiment 1~4

[0090] Embodiment 1~4, comparative example 1

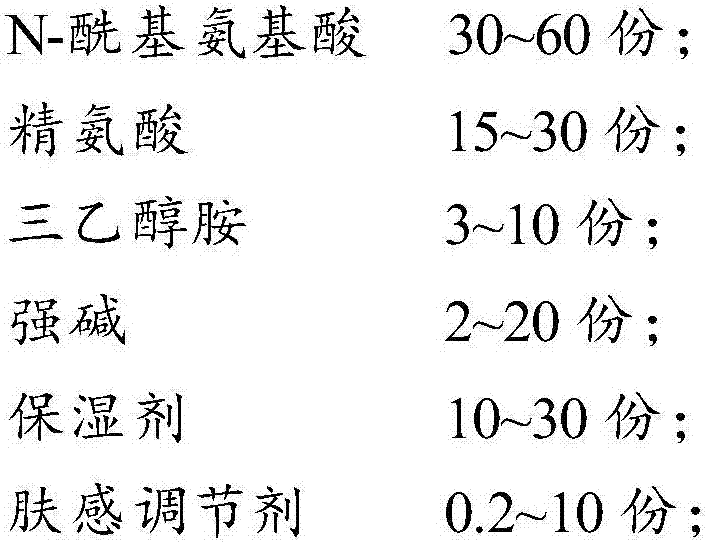

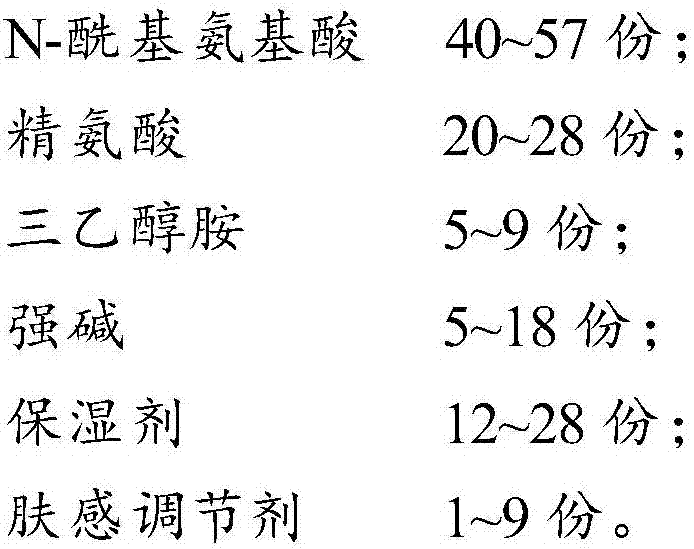

[0091] (1) Formulation:

[0092]

[0093]

[0094] (2) Preparation method

[0095] 1) Mix the weighed lauroyl glutamic acid, glycerin and 50% of the rest of water, stir at a constant speed and heat to 90°C.

[0096] 2) Weigh triethanolamine, arginine, sodium hydroxide, and the rest of water, heat to 90°C, add step 1) slowly, stir well, and then add polyglycerol-10.

[0097] 3) Cool down to 70°C, add folic acid, niacinamide, vitamin B6, vitamin B12, creatine, pigment and essence.

[0098] 4) Put it into the mold and fill it after static defoaming.

[0099] (3) Quality evaluation

[0100] Each measurement index value of embodiment and comparative example

[0101]

[0102] The human body trial score of embodiment and comparative example

[0103]

Embodiment 5~8

[0104] Embodiment 5~8, comparative example 2

[0105]

[0106] (2) Preparation method

[0107] 1) Mix cocoyl glutamic acid, myristoyl glutamic acid, stearyl glutamic acid, glycerin, sorbitol, and propylene glycol with 50% of the remaining water, stir and heat to 80°C.

[0108] 2) Weigh triethanolamine, arginine, potassium hydroxide and the rest of water, heat to 80°C, slowly add step 1), stir evenly, add betaine, urea, allantoin, seaweed extract.

[0109] 3) Cool down to 65°C, add folic acid, niacinamide, vitamin B12, creatine, pigment and essence.

[0110] 4) Put it into the mold and fill it after static defoaming.

[0111] (3) Quality evaluation

[0112] Each measurement index value of embodiment and comparative example

[0113]

[0114] The human body trial score of embodiment and comparative example

[0115]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com