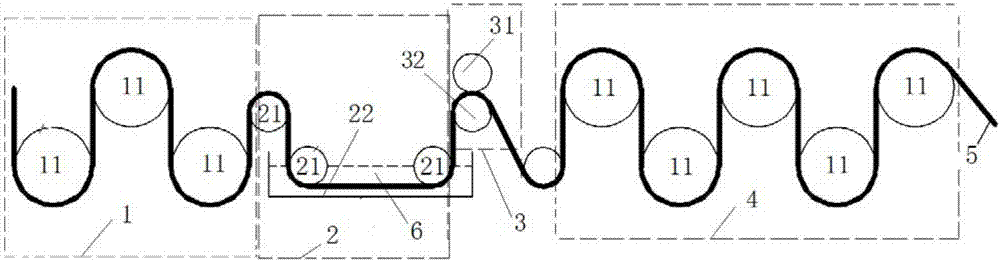

System for water-washing drying, sizing and drying setting of carbon fiber

A carbon fiber and drying technology, which is used in textiles and papermaking, textile material processing, continuous processing of textile materials, etc. Affect the final material properties and other issues, to achieve the effect of reducing electricity costs, saving floor space, and maintaining uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

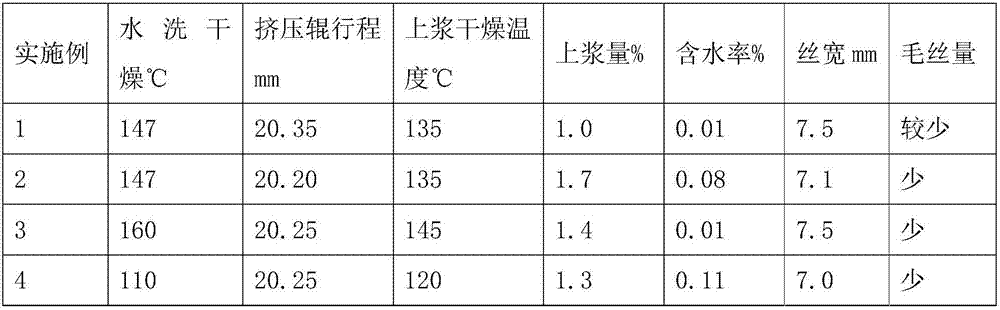

Embodiment 1

[0033] The temperature of the washing and drying hot roller is raised in advance, and the temperature setting value is 147°C. After rising to the target temperature, the washed 12K T700 carbon fiber is inserted into the washing and drying hot roller unit at a line speed of 8m / min.

[0034] Prepare a slurry with a concentration of 4.5%, mix it evenly, put it into the sizing tank through a circulating pump, and turn on the temperature control system. When the temperature of the slurry in the tank is 25±2°C, connect the carbon fiber from the washing and drying hot roller unit, and then The sizing process is completed through each transmission smooth roller. When the carbon fiber passes through the second extrusion roller, the hand valve is used to close the extrusion rubber roller group, and the stroke scales on both sides of the first extrusion roller are kept consistent for extrusion. Both are 20.35mm.

[0035] The temperature of the hot roller group of the drying and setting s...

Embodiment 2

[0037] Adopt the same water washing drying and sizing drying temperature as in Example 1, but the difference from Example 1 is that the stroke of the squeezing roller is 20.20mm.

Embodiment 3

[0039] The temperature of the water-washing and drying hot roller is raised in advance, and after the temperature is raised to 160°C, the water-washed carbon fiber is inserted into the water-washing and drying hot roller unit at a line speed of 8m / min.

[0040] Prepare a slurry with a concentration of 4.5%, mix it evenly, put it into the sizing tank through a circulating pump, and turn on the temperature control system. When the temperature in the tank is controlled at 25±2°C, the carbon fiber of the washing and drying hot roller unit passes through each transmission light in turn. The roller completes the sizing process. When the carbon fiber passes through the second extrusion roller, use the hand valve to close the extrusion rubber roller group, and keep the stroke scales on both sides of the first extrusion roller consistent for extrusion. The strokes on both sides are 20.25mm .

[0041] Heat up the hot roller of the drying and setting system in advance, and insert the car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com