Sand wash process for modal yarns

A technology of sand washing and yarn, applied in the field of sand washing process of modal yarn, can solve the problems of easily irritating the skin and affecting the wearing comfort of underwear, and achieve the effect of improving the antistatic ability, improving the hand feeling and reducing the directional friction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

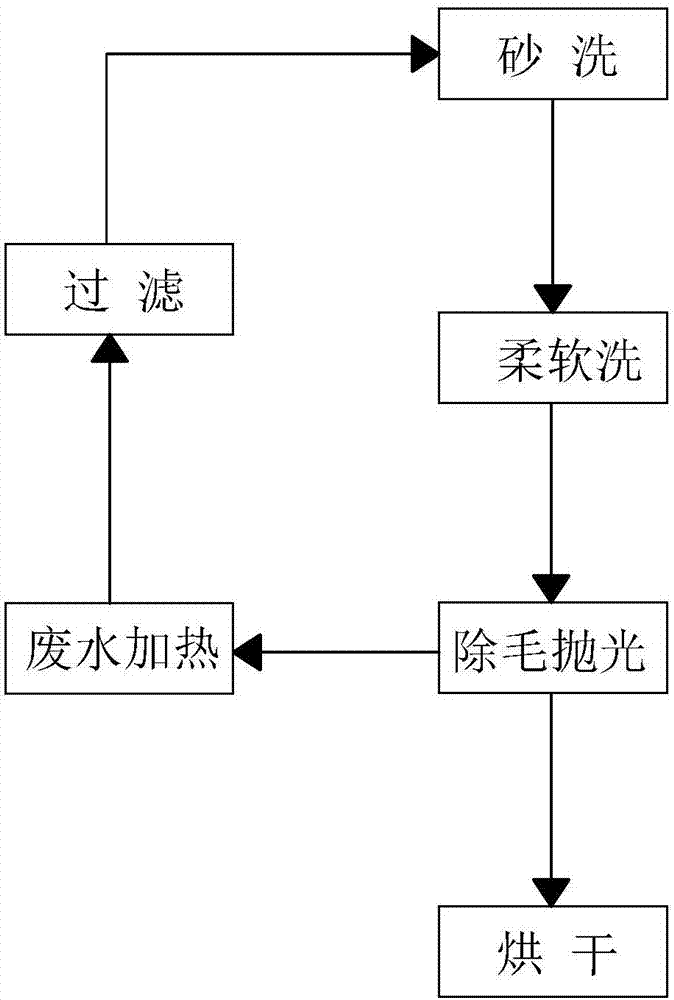

[0032] Such as figure 1 Shown, a kind of sand washing process of modal yarn, comprises the following steps:

[0033] (1) Sand washing: Put the modal yarn into the sand washing machine, add water, the bath ratio is 1:30-55, and add pH buffer solution into the sand washing machine, the pH buffer solution is citric acid-sodium citrate Buffer system, adjust the pH value at 4.8-5.8, raise the temperature to 65-85°C, stir for 10-20 minutes, add sand washing agent, sand washing agent includes compound potassium permanganate slow-release agent, stir for 10-25 minutes Finally, dehydrate and wash with water;

[0034] (2) Soft washing: add a softener to the sand washing machine, the softener includes an ester-based quaternary ammonium salt softener, the concentration of the softener is 5-8g / L, the bath ratio is 20:1, and stir at room temperature for 20 minutes , washed with clean water and then dehydrated; recycle the removed waste water, heat the waste water to 90-100°C, keep it for 1...

Embodiment 2

[0038] A kind of sand washing process of modal yarn, comprises the following steps:

[0039](1) Sand washing: Put the modal yarn into the sand washing machine, add water, the bath ratio is 1:30-55, and add pH buffer solution into the sand washing machine, the pH buffer solution is citric acid-sodium citrate Buffer system, adjust the pH value at 4.8-5.8, raise the temperature to 55-65°C, stir for 10-20 minutes, add sand wash, sand wash includes compound potassium permanganate slow-release agent, stir for 10-25 minutes Finally, dehydrate and wash with water;

[0040] (2) Soft washing: add softener to the sand washing machine, the softener includes ester quaternary ammonium salt softener, the concentration of the softener is 4-7g / L, the bath ratio is 20:1, stir at room temperature for 20 minutes , washed with clean water and then dehydrated; recycle the removed waste water, heat the waste water to 90-100°C, keep it for 10-15 minutes, filter while it is hot to remove impurities i...

Embodiment 3

[0044] A kind of sand washing process of modal yarn, comprises the following steps:

[0045] (1) Sand washing: put the modal yarn into the sand washing machine, add water, the bath ratio is 1:30-55, and add pH buffer solution into the sand washing machine, the pH buffer solution is acetic acid-sodium acetate buffer system , adjust the pH value at 4.8-5.8, raise the temperature to 60-80°C, stir for 10-20 minutes, add sand washing agent, sand washing agent includes compound potassium permanganate slow-release agent, after stirring for 10-25 minutes, Dehydrated, washed with water;

[0046] (2) Soft washing: add a softener to the sand washing machine, the softener includes an ester-based quaternary ammonium salt softener, the concentration of the softener is 6-8g / L, the bath ratio is 20:1, and stir at room temperature for 20 minutes , washed with clean water and then dehydrated; recycle the removed waste water, heat the waste water to 90-100°C, keep it for 10-15 minutes, filter w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com