Preparation method of polyphosphazene polymer microspheres

A technology of polymer microspheres and polyphosphazene is applied in the field of functional materials to achieve the effects of wide application prospect, convenient operation and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Add 50 mL of acetonitrile, 0.1 g of 4,4'-dihydroxydiphenyl sulfone, 0.18 g of bisphenol AF and 0.5 mL of triethylamine into a three-necked flask, and heat at 90 o C, stirring at 200 r / min, condensing and refluxing;

[0017] (2) Add 0.2 g of hexachlorotrimeric phosphazene into the three-necked flask in step (1), stir, condense and reflux, and react for 1 h;

[0018] (3) The product of step (2) was cooled to room temperature, then centrifuged, washed with acetone, ethanol and distilled water, and finally dried in vacuum for 24 h.

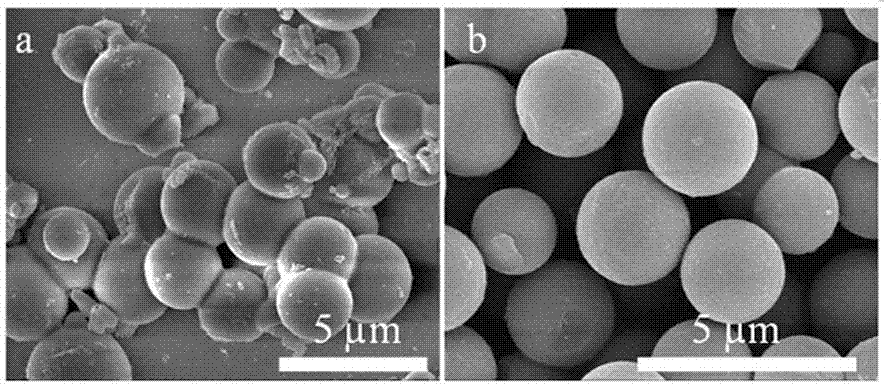

[0019] The particle size of the prepared polyphosphazene microspheres was 500 nm.

Embodiment 2

[0021] (1) Add 50 mL of acetone-acetonitrile mixed solution (the volume ratio of acetone and acetonitrile is 1:1), 0.13 g of 4,4'-dihydroxydiphenyl sulfone, 0.1 g of bisphenol AF and 1.0 mL of trioctyl Amine, heating temperature is 20 o C, stirring at 200 r / min, condensing to reflux;

[0022] (2) Add 0.3 g of hexachlorotrimeric phosphazene into the three-necked flask in step (1), stir, condense and reflux, and react for 3 h;

[0023] (3) The product of step (2) was cooled to room temperature, then centrifuged, washed with acetone, ethanol and distilled water, and finally dried in vacuum for 24 h.

[0024] The prepared polyphosphazene microspheres had a particle size of 1.5 µm

Embodiment 3

[0026] (1) Add 50 mL of acetone solution, 0.25 g of 4,4'-dihydroxydiphenyl sulfone, 0.05 g of bisphenol AF and 1.5 mL of trioctylamine into a three-necked flask, and heat at 50 o C, stirring at 200 r / min, condensing and refluxing;

[0027] (2) Add 0.2 g of hexachlorotrimeric phosphazene into the three-necked flask in step (1), stir, condense and reflux, and react for 4 h;

[0028] (3) The product of step (2) was cooled to room temperature, then centrifuged, washed with acetone, ethanol and distilled water, and finally dried in vacuum for 24 h.

[0029] The particle size of the prepared polyphosphazene microspheres was 2.7 µm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com