Circuit board UV ink with high temperature resistance and preparation method thereof

A circuit board and high temperature resistant technology, which is applied in the field of high temperature resistant circuit board UV ink and its preparation, can solve the problems of poor high temperature resistance and weak adhesion, and achieve low cost, scientific formula, suitable for large-scale industrial production and Promoted app performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

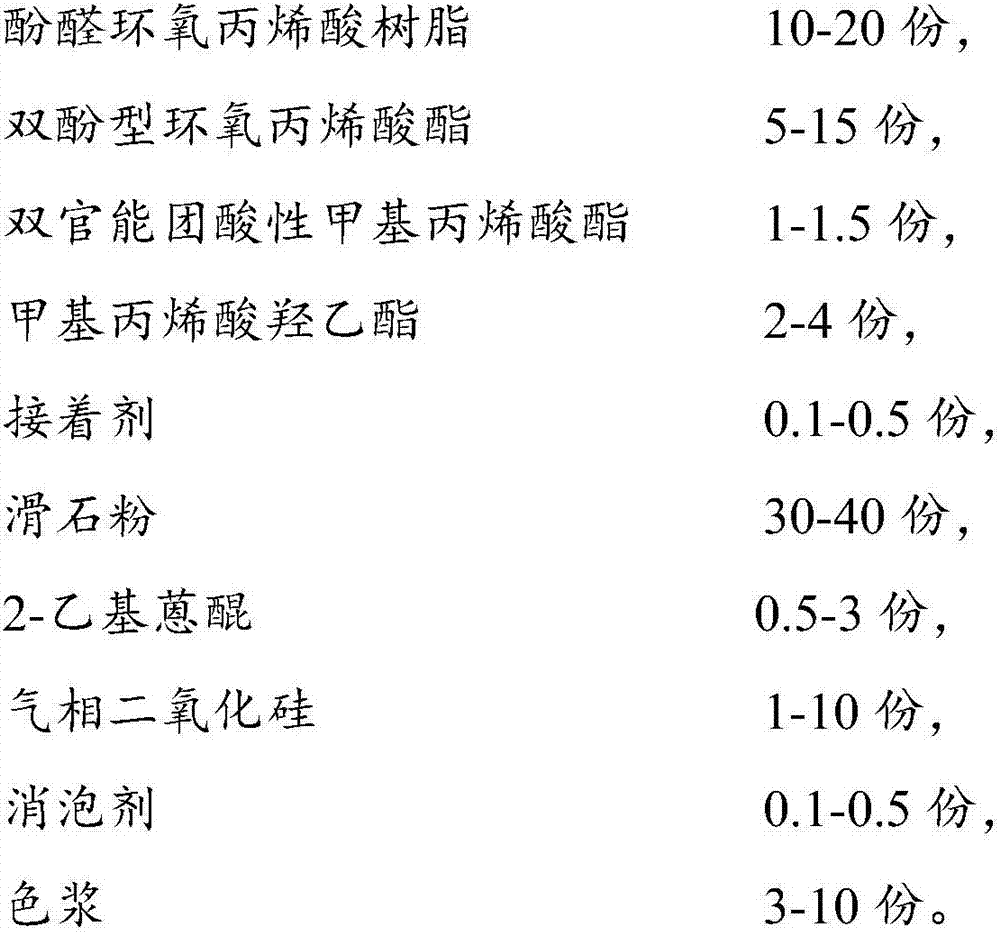

[0032] A kind of high temperature resistant circuit board UV ink, by weight, comprises the following components:

[0033]

[0034]

[0035] A preparation method of high temperature resistant circuit board UV ink, comprising the following steps:

[0036] (1) Add novolac epoxy acrylic resin, bisphenol A diglycidyl ether diacrylate, adhesive, 2-ethylanthraquinone, and color paste into the mixing container according to the number of parts, and stir at high speed for 2 to 3 hours to make it Completely dissolve to obtain mixture A, while controlling the temperature of this process to ≤50°C;

[0037] (2) Add talcum powder to mixture A, stir for 0.5-3 hours, then slowly add fumed silica while stirring, and obtain mixture B after uniform dispersion, while controlling the temperature in this process to ≤65°C;

[0038] (3) Grinding the mixture B to a fineness of ≤40um, and then standing still for 10-20h to obtain the semi-finished product A;

[0039] (4) Add bifunctional acidic m...

Embodiment 2

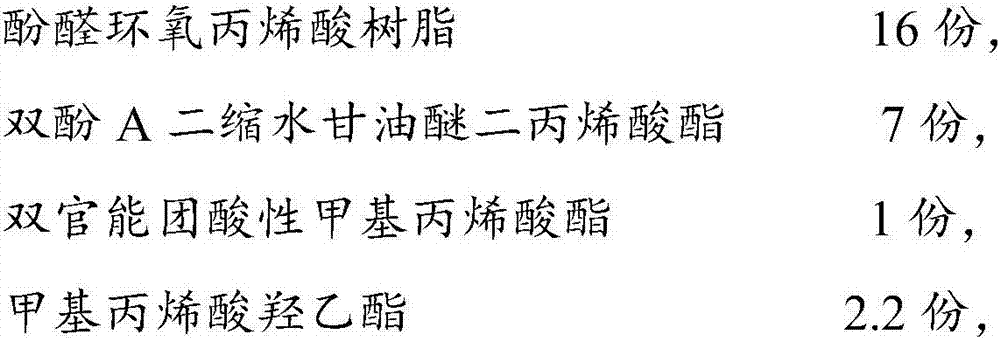

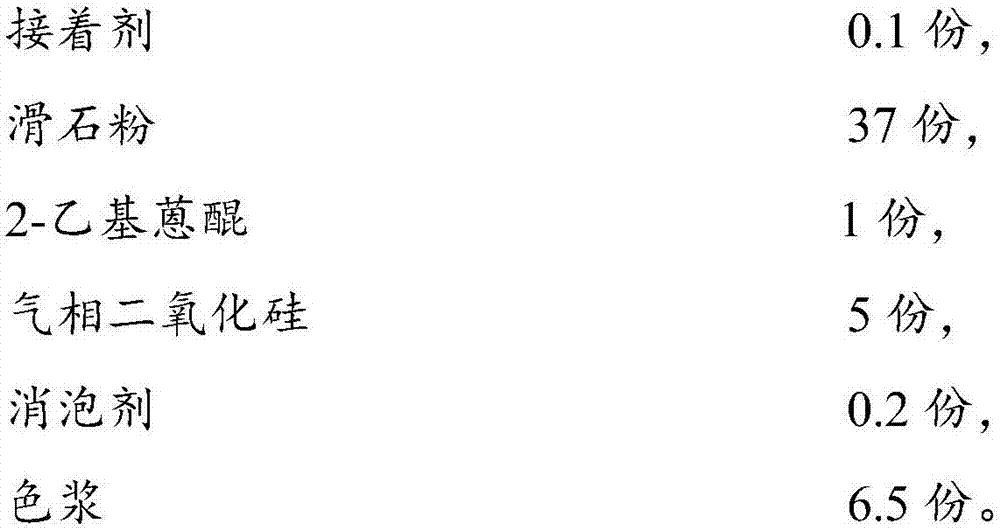

[0043] A kind of high temperature resistant circuit board UV ink, by weight, comprises the following components:

[0044]

[0045]

[0046] A preparation method of high temperature resistant circuit board UV ink, comprising the following steps:

[0047] (1) Add novolac epoxy acrylic resin, bisphenol A diglycidyl ether diacrylate, adhesive, 2-ethylanthraquinone, and color paste into the mixing container according to the number of parts, and stir at high speed for 2 to 3 hours to make it Completely dissolve to obtain mixture A, while controlling the temperature of this process to ≤50°C;

[0048] (2) Add talcum powder to mixture A, stir for 0.5-3 hours, then slowly add fumed silica while stirring, and obtain mixture B after uniform dispersion, while controlling the temperature in this process to ≤65°C;

[0049] (3) Grinding the mixture B to a fineness of ≤40um, and then standing still for 10-20h to obtain the semi-finished product A;

[0050] (4) Add bifunctional acidic m...

Embodiment 3

[0054] A kind of high temperature resistant circuit board UV ink, by weight, comprises the following components:

[0055]

[0056]

[0057] A preparation method of high temperature resistant circuit board UV ink, comprising the following steps:

[0058] (1) Add novolac epoxy acrylic resin, bisphenol A diglycidyl ether diacrylate, adhesive, 2-ethylanthraquinone, and color paste into the mixing container according to the number of parts, and stir at high speed for 2 to 3 hours to make it Completely dissolve to obtain mixture A, while controlling the temperature of this process to ≤50°C;

[0059] (2) Add talcum powder to mixture A, stir for 0.5-3 hours, then slowly add fumed silica while stirring, and obtain mixture B after uniform dispersion, while controlling the temperature in this process to ≤65°C;

[0060] (3) Grinding the mixture B to a fineness of ≤40um, and then standing still for 10-20h to obtain the semi-finished product A;

[0061] (4) Add bifunctional acidic m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com