A cathode material for lithium-sulfur batteries bounded by a graphene conductive network for lithium polysulfides

A lithium polysulfide and lithium-sulfur battery technology, applied in the field of electrochemistry, can solve problems such as unsatisfactory electrical properties, and achieve the effects of improving conductivity, improving rate characteristics, and increasing cycle times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

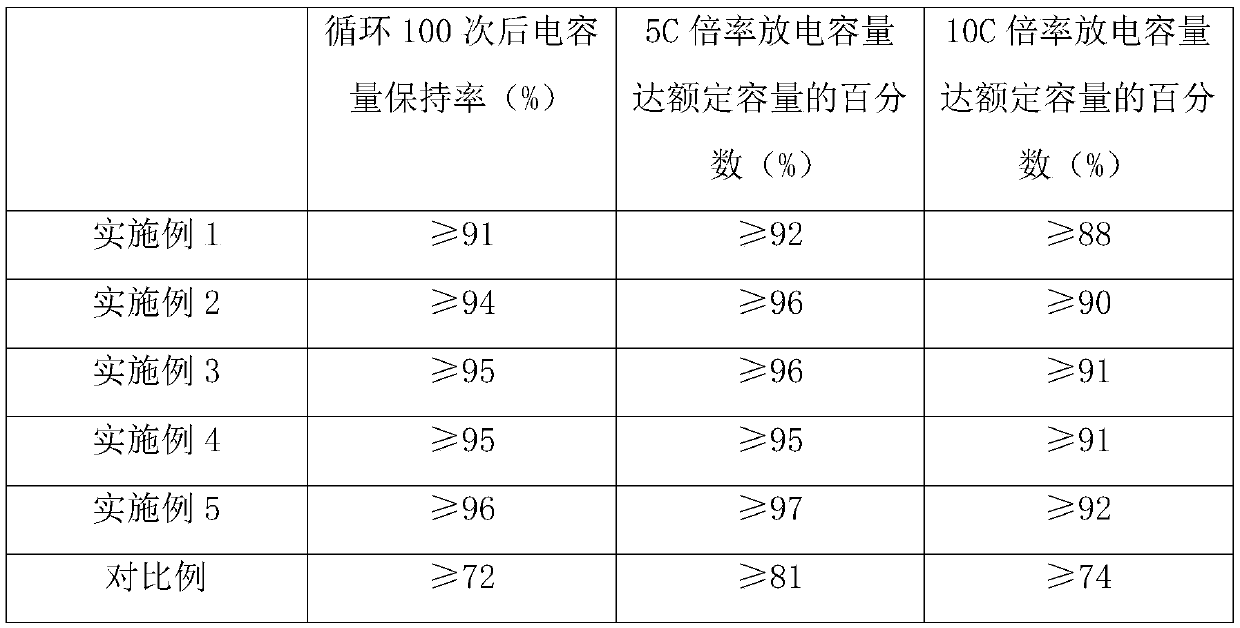

Examples

Embodiment 1

[0029] The lithium-sulfur battery positive electrode material constrained by the graphene conductive network of lithium polysulfide is made of the following components in parts by weight: 1 part of graphene microsheet, 6 parts of lithium polysulfide powder, polyimide ( 1 part of PI) solution, 5 parts of organic carbon source (glucose) aqueous solution, wherein, the mass percent of organic carbon source (glucose) in the organic carbon source (glucose) aqueous solution is 3%.

[0030] Wherein, the particle size of the lithium polysulfide powder is 100 nm.

[0031] The preparation method of above-mentioned cathode material, specific steps are as follows:

[0032] (1) adding the graphene microchips into the organic carbon source (glucose) aqueous solution, mixing evenly, and ultrasonically dispersing;

[0033] (2) Add lithium polysulfide powder, stir and mix, and carbonize under the protection of nitrogen to form a core-shell structure with ion channels to obtain material I;

[...

Embodiment 2

[0036] The anode material for lithium-sulfur battery constrained lithium polysulfide by graphene conductive network is made of the following components in parts by weight: 2 parts of graphene microsheets, 8 parts of lithium polysulfide powder, polyimide ( 1 part of PI) solution, 10 parts of organic carbon source (sucrose) aqueous solution, wherein, the mass percentage of organic carbon source (sucrose) in the organic carbon source (sucrose) aqueous solution is 15%.

[0037] Wherein, the particle size of the lithium polysulfide powder is 200 nm.

[0038] The preparation method of above-mentioned cathode material, specific steps are as follows:

[0039] (1) adding the graphene microchips into the organic carbon source (sucrose) aqueous solution, mixing evenly, and ultrasonically dispersing;

[0040] (2) Add lithium polysulfide powder, stir and mix, and carbonize under the protection of nitrogen to form a core-shell structure with ion channels to obtain material I;

[0041] (3)...

Embodiment 3

[0047] The cathode material for lithium-sulfur batteries constrained by the graphene conductive network to lithium polysulfide, in parts by weight, is made of the following components: 1 part of graphene microchips, 8 parts of lithium polysulfide powder, polyimide ( 1 part of PI) solution, 5 parts of organic carbon source (glucose) aqueous solution, wherein the mass percent of organic carbon source (glucose) in the organic carbon source (glucose) aqueous solution is 15%.

[0048] Wherein, the particle size of the lithium polysulfide powder is 100 nm.

[0049] The preparation method of above-mentioned cathode material, specific steps are as follows:

[0050] (1) adding the graphene microchips into the organic carbon source (glucose) aqueous solution, mixing evenly, and ultrasonically dispersing;

[0051] (2) Add lithium polysulfide powder, stir and mix, and carbonize under the protection of nitrogen to form a core-shell structure with ion channels to obtain material I;

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com