Semi-solid lithium liquid battery system and working method thereof

A semi-solid, flow battery technology, applied in the direction of fuel cells, fuel cell additives, regenerative fuel cells, etc., can solve the problems of unfavorable suspension stable transportation, reduce battery Coulomb efficiency, etc., to prevent leakage, avoid battery leakage, Effect of battery cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

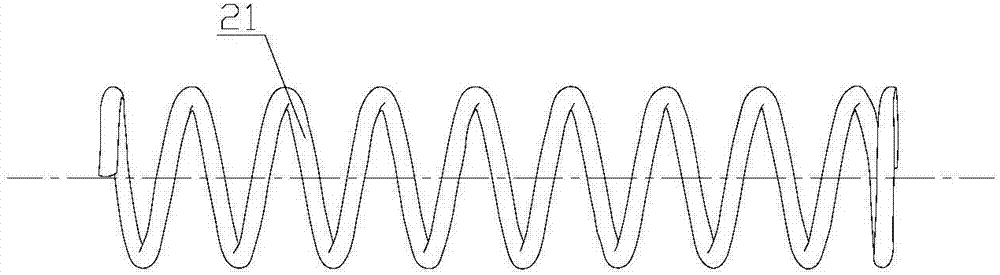

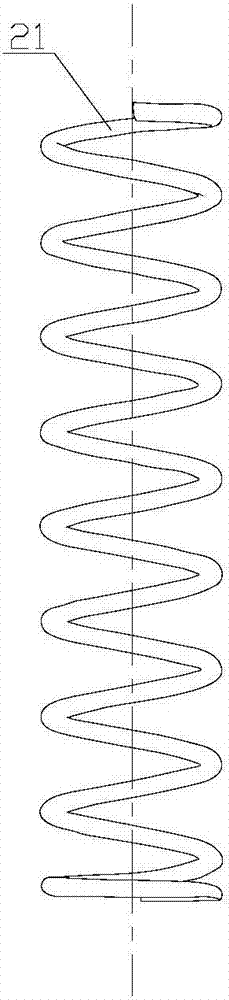

[0053] The material of the positive electrode liquid storage pipe 21 and the negative electrode liquid storage pipeline 21' is an insulating and corrosion-resistant material: polyvinyl chloride, polyethylene, polypropylene, polystyrene, polytetrafluoroethylene, polyethylene terephthalate, Nylon, polyimide, polyethernitrile, polyvinylidene fluoride, modified polyolefin, fluorosilicone rubber, dimethyl silicone rubber, methyl vinyl silicone rubber, nitrile silicone rubber, phenylene and phenylene ether silicone rubber One or a combination of several.

Embodiment 2

[0055] The positive electrode liquid storage pipe 21 and the negative electrode liquid storage pipeline 21' are stainless steel pipes.

Embodiment 3

[0057] The main body material of the positive electrode liquid storage pipe 21 and the negative electrode liquid storage pipeline 21' is stainless steel, the inner lining is stainless steel, and the outer surface is the above-mentioned insulating and corrosion-resistant material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com