Azoxystrobin suspension concentrate with particle sizes of less than 100nm and preparation method of azoxystrobin suspension concentrate

A water suspension, azoxystrobin technology, applied in botany equipment and methods, fungicides, chemicals for biological control, etc., can solve Oswald ripening, wide particle size distribution, stratification or agglomeration, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] Example 1: Preparation of 30mL azoxystrobin nano-water suspension (containing 3mg azoxystrobin technical, 3-30 μL Tween 80 and 3.0mL ethanol):

[0029] Dissolve 3 μL Tween 80 and 3 mg azoxystrobin original drug in 3.0 mL ethanol to form an organic phase.

[0030] Take 3 mL of water as the aqueous phase.

[0031] The aqueous phase and the organic phase were respectively injected into the two micro-cavities of the mixer, so that the two micro-cavities were jetted against each other, and the mixing took about 5 seconds in total. Collect the mixed solution with 24 mL of water to obtain 30 mL of azoxystrobin nanosuspension.

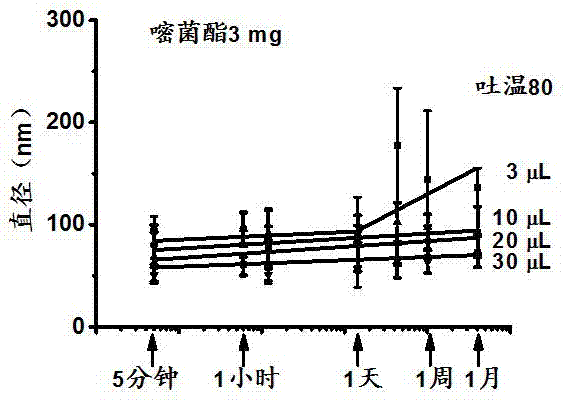

[0032] Using the same method, 10, 20, and 30 μL of Tween 80 were used to repeat the above experiments to prepare nano-suspensions with different Tween-80 contents, and the size of the suspensions was measured by dynamic light scattering, and the stability over time was tracked.

[0033] like figure 1 As shown, when the dosage of Tween 80 is 10-30 μL ...

example 2

[0034] Example 2: Preparation of 30mL azoxystrobin nano-scale aqueous suspension (containing 3mg azoxystrobin technical, 0.6-3mg PLGA-PEG and 3.0 mL acetone):

[0035] Take 0.6 mg amphiphilic copolymer PLGA-PEG and 3 mg azoxystrobin original drug dissolved in 3.0 mL acetone to form an organic phase.

[0036] Take 3 mL of water as the aqueous phase.

[0037] The aqueous phase and the organic phase are respectively injected into the two micro-chambers of the mixer, so that the two micro-chambers are jetted against each other, and the mixing takes about 5 seconds in total. Collect with a container containing 24ml of water to obtain 30mL of azoxystrobin suspension.

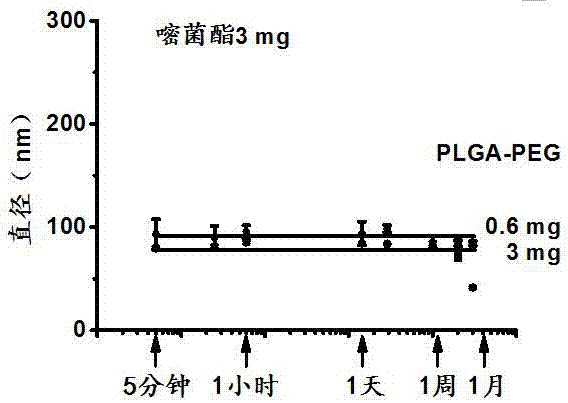

[0038] And with the same method, take 3mg PLGA-PEG to repeat the above experiment, and make 30mL corresponding azoxystrobin nanosuspension. The suspending agent was measured by the dynamic light scattering method, and the initial average diameter was 83nm, and the PDI was 0.29. And track the time stability (such as...

example 3

[0040] Example 3: Comparison of the preparation by drop stirring method and jet hedging mixing method (30mL nano-scale aqueous suspension contains 3mg azoxystrobin original drug, 3mg PLGA-PEG and 3.0mL propanol):

[0041] Dissolve 3 mg of PLGA-PEG and 3 mg of azoxystrobin in 3.0 mL of propanol to form an organic phase.

[0042] Take 3 mL of water as the aqueous phase.

[0043]The aqueous phase and the organic phase were respectively injected into the two micro-cavities of the mixer, so that the two micro-cavities were jetted against each other, and the mixing took about 5 seconds in total. Collect with a container containing 24ml of water to obtain 30mL of azoxystrobin suspension.

[0044] With the same ratio, configure the aqueous phase and the organic phase, slowly add 27mL of water to 3mL of the organic phase dropwise, and at a rotation speed of 900rpm, drop it within 2 hours to obtain 30mL of azoxystrobin suspension.

[0045] Suspensions were tested for temporal stabilit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Primary particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com