Method for preparing graphene oxide

A technology of graphene and graphite, which is applied in the field of graphene oxide preparation, can solve problems such as low electrical conductivity and damage to the lattice structure of graphene oxide, and achieve the effect of improving electrical conductivity, simple and easy preparation steps, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The invention provides a kind of preparation method of graphene oxide, comprises the following steps:

[0053] A) after graphite, intercalation agent and auxiliary intercalation agent are mixed, carry out reaction, obtain reaction mixture;

[0054] B) After cooling down, react the reaction mixture obtained in the above steps with the oxidizing agent again, add water, and then heat up the reaction to obtain the intermediate system;

[0055] The mass ratio of the graphite to the oxidant is 1: (1.5-2.0);

[0056] C) after the intermediate system obtained in the above steps is continued to react with the reducing agent, graphene oxide is obtained;

[0057] In the graphene oxide, the molar ratio of carbon element to oxygen element is (1.6-2):1.

[0058] In the invention, graphite, intercalation agent and auxiliary intercalation agent are firstly mixed and then reacted to obtain a reaction mixture.

[0059] The present invention does not have special limitation to describe...

Embodiment 1

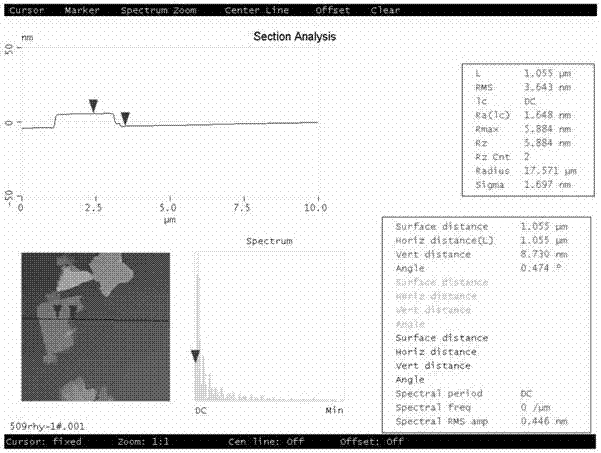

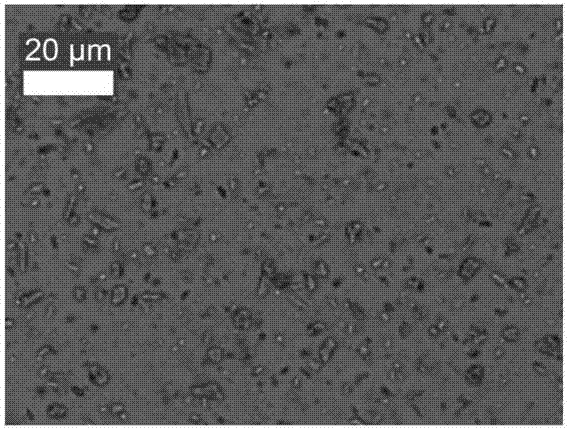

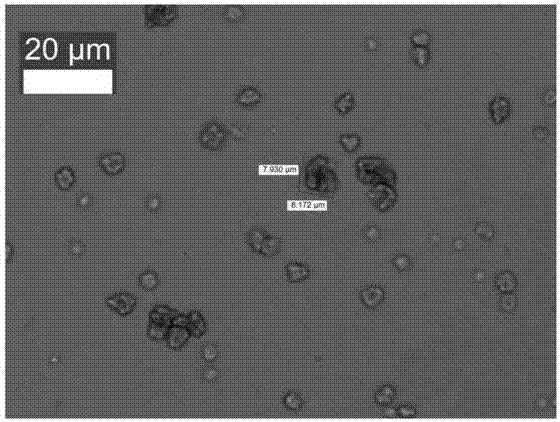

[0098] Disperse 20g of natural flake graphite with a particle size of 20μm in 700ml of 98% concentrated sulfuric acid at room temperature, add 10ml of fuming nitric acid after stirring for 1 hour, and control the reaction temperature below 10°C after 12 hours of reaction. °C for 50 hours. Use a constant pressure dropping funnel to control the temperature below 50°C and add 0.65L of high-purity water dropwise. Raise the temperature to 90°C for 2 hours, then lower the temperature to about 50°C, and add 20ml of hydrogen peroxide. Naturally lower the temperature and perform ultrasonic cleaning to obtain a single-layer graphene oxide solution.

[0099] The graphene oxide prepared in Example 1 of the present invention was analyzed for organic elements, see Table 1, Table 1 is the elemental analysis table of the graphene oxide prepared in Example 1 of the present invention.

[0100] Table 1

[0101]

[0102] It can be seen from Table 1 that the carbon-to-oxygen molar ratio prep...

Embodiment 2

[0110] Disperse 60g of natural flake graphite with a particle size of 10μm in 2000ml of 98% concentrated sulfuric acid at room temperature, add 45ml of fuming nitric acid after stirring for 1 hour, and add 108g of potassium permanganate after 12 hours of reaction to control the reaction temperature below 10°C. °C for 50 hours. Use a constant-pressure dropping funnel to control the temperature below 50°C and add 2L of high-purity water dropwise. Raise the temperature to 90°C for 2 hours, then lower the temperature to about 50°C, and add 60ml of hydrogen peroxide. Naturally lower the temperature and perform ultrasonic cleaning to obtain a single-layer graphene oxide solution.

[0111] The graphene oxide prepared in Example 2 of the present invention was analyzed for organic elements, see Table 3, Table 3 is the elemental analysis table of the graphene oxide prepared in Example 2 of the present invention.

[0112] table 3

[0113]

[0114] As can be seen from Table 3, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com