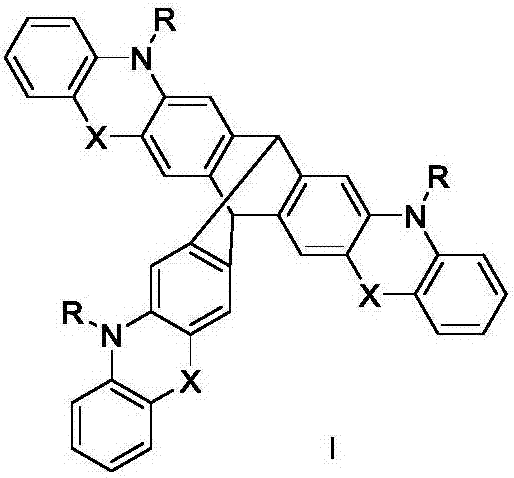

Novel organic electroluminescent material and organic light-emitting device

An electroluminescent material and organic technology, applied in the direction of luminescent materials, electrical solid devices, electrical components, etc., can solve the problems of triplet inactivation, high device driving voltage, and efficiency roll-off, so as to reduce fluorescence quenching and improve The effect of luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

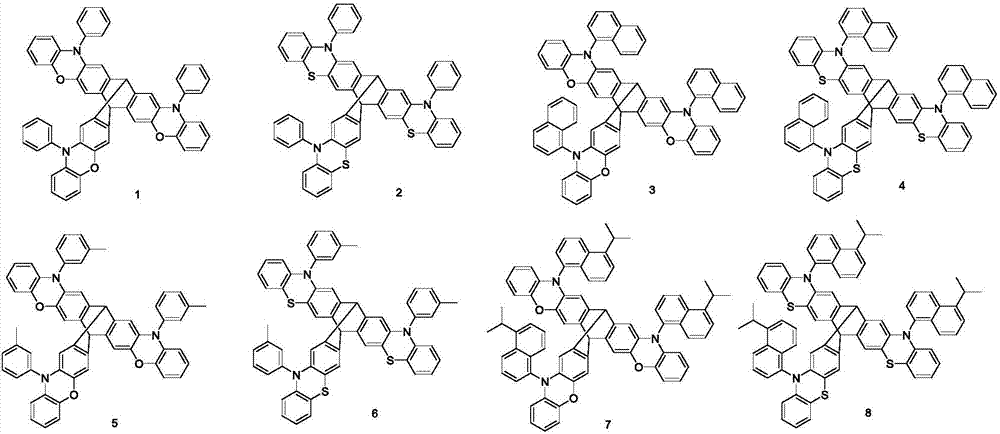

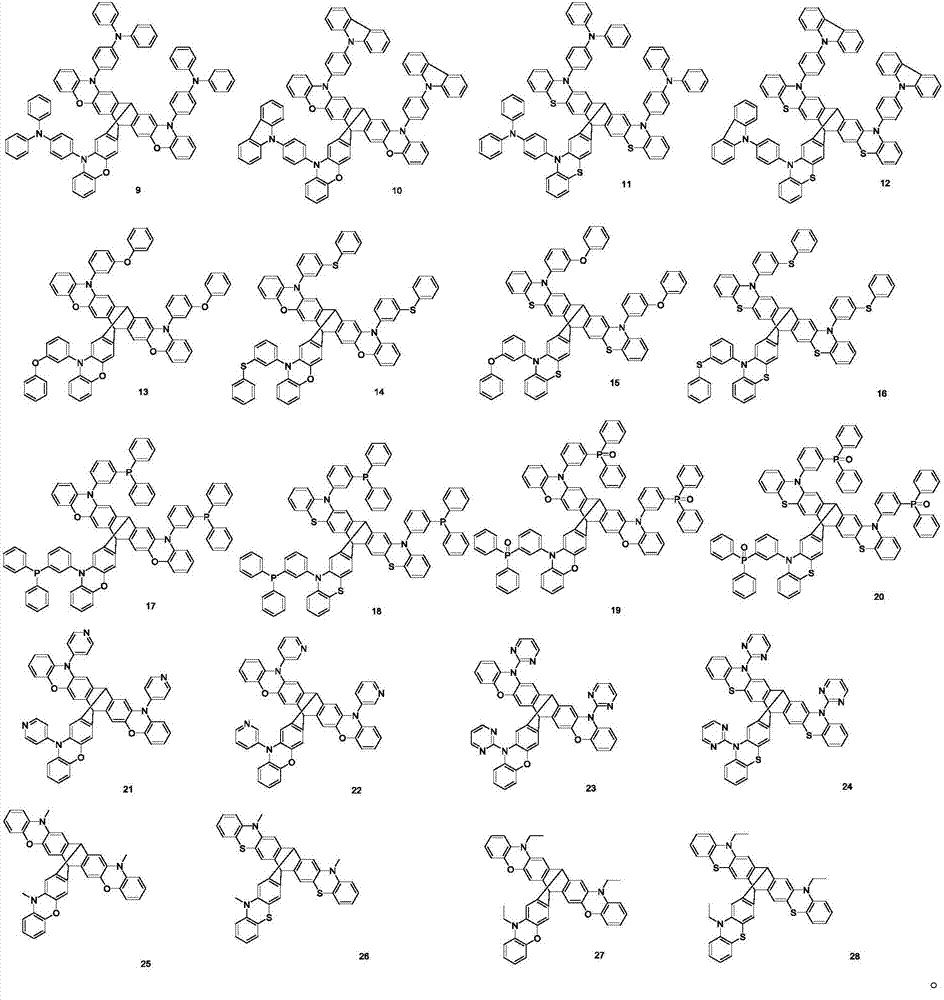

Examples

Embodiment 1

[0039] Embodiment 1: 1 synthesis of compound

[0040]

[0041] Step1. Add 100mmol tripterene into 1L concentrated nitric acid, and react the mixture at 75°C for 24h. The resulting brown solution was cooled to room temperature. Add 5 L of ice water, stir, and filter the filter cake, wash with deionized water, and dry. The obtained crude product was subjected to column chromatography to obtain 64 mmol of the product. Yield 64%.

[0042] Dissolve 64 mmol of the nitrated product of tripterene in THF, add 10 equivalents of hydrazine hydrate and 5 equivalents of Raney nickel, and react at 60°C for 24 hours. The mixture was cooled to room temperature, filtered, and the filtrate was concentrated to obtain a white product, which was subjected to column chromatography to obtain 59 mmol of tripterene amide.

[0043] Dissolve 59 mmol of tripterene amination in concentrated hydrochloric acid, cool to 0°C, slowly add 3 equivalents of sodium nitrite aqueous solution, and stir for 10 m...

Embodiment 2

[0047] Embodiment 2: 2 synthesis of compound

[0048]

[0049] Step1. Add 100mmol tripterene into 1L concentrated nitric acid, and react the mixture at 75°C for 24h. The resulting brown solution was cooled to room temperature. Add 5 L of ice water, stir, and filter the filter cake, wash with deionized water, and dry. The obtained crude product was subjected to column chromatography to obtain 64 mmol of the product. Yield 64%.

[0050] Dissolve 64 mmol of the nitrated product of tripterene in THF, add 10 equivalents of hydrazine hydrate and 5 equivalents of Raney nickel, and react at 60°C for 24 hours. The mixture was cooled to room temperature, filtered, and the filtrate was concentrated to obtain a white product, which was subjected to column chromatography to obtain 59 mmol of tripterene amide.

[0051] Dissolve 59 mmol of tripterene amination in concentrated hydrochloric acid, cool to 0°C, slowly add 3 equivalents of sodium nitrite aqueous solution, and stir for 10 m...

Embodiment 3

[0055] Embodiment 3: 21 synthetics of compound

[0056]

[0057] Step1. Add 100mmol tripterene into 1L concentrated nitric acid, and react the mixture at 75°C for 24h. The resulting brown solution was cooled to room temperature. Add 5 L of ice water, stir, and filter the filter cake, wash with deionized water, and dry. The obtained crude product was subjected to column chromatography to obtain 64 mmol of the product. Yield 64%.

[0058] Dissolve 64 mmol of the nitrated product of tripterene in THF, add 10 equivalents of hydrazine hydrate and 5 equivalents of Raney nickel, and react at 60°C for 24 hours. The mixture was cooled to room temperature, filtered, and the filtrate was concentrated to obtain a white product, which was subjected to column chromatography to obtain 59 mmol of tripterene amide.

[0059] Dissolve 59 mmol of tripterene amination in concentrated hydrochloric acid, cool to 0°C, slowly add 3 equivalents of sodium nitrite aqueous solution, and stir for 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com