Antibacterial acrylic board and its preparation method

An acrylic board and inorganic antibacterial agent technology, applied in the field of composite boards, can solve the problems of low energy consumption for dissolution and recovery, serious environmental pollution, and high solvent toxicity, and achieve good comprehensive mechanical properties, simple raw material components, and good antibacterial properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

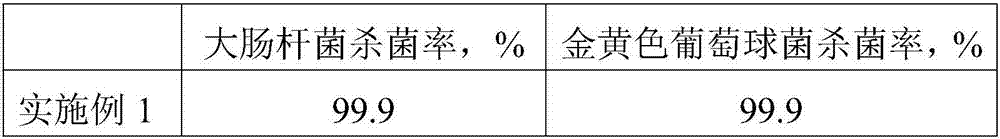

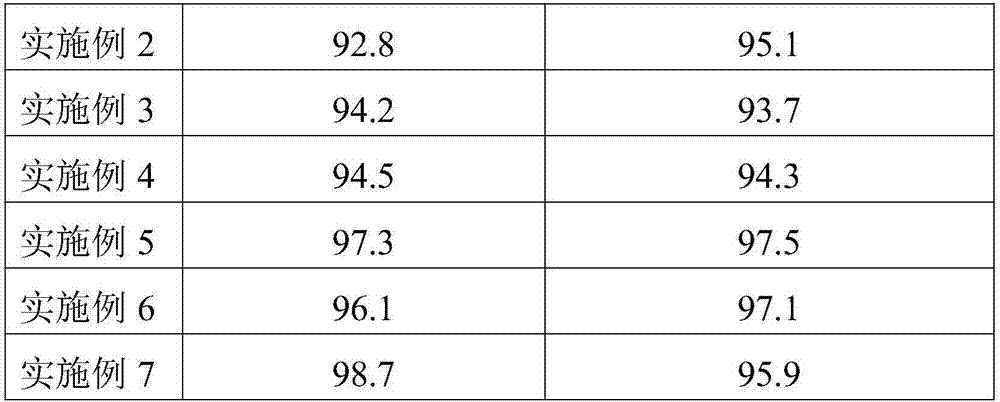

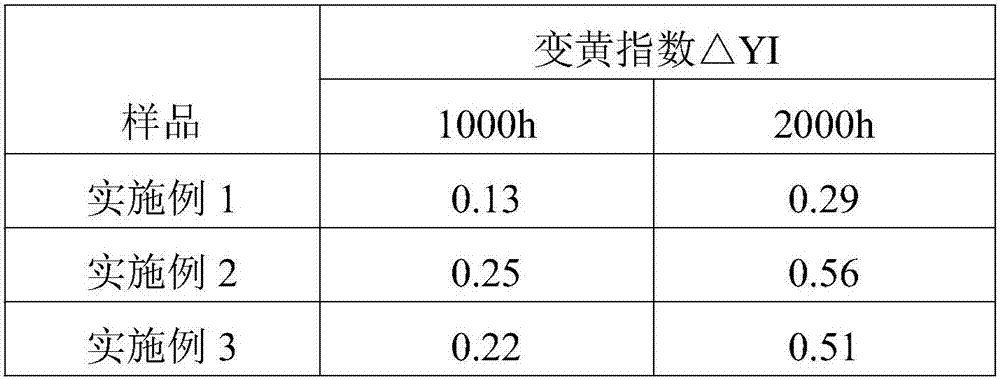

Examples

Embodiment 1

[0032] Raw materials of antibacterial acrylic board: 100 kg of methyl methacrylate, 0.8 kg of dicumyl peroxide, 20 kg of fly ash, 0.4 kg of 3-(2,3-epoxypropoxy)propyltrimethoxysilane, 0.2 kg of methyl silicone oil, 3 kg of inorganic antibacterial agent, and 0.69 kg of ultraviolet absorber.

[0033] The inorganic antibacterial agent is obtained by uniformly stirring and mixing zinc stannate, zinc titanate and zinc molybdate in a mass ratio of 1:1:1.

[0034] The ultraviolet absorber is composed of 1-(methyl)-8-(1,2,2,6,6-pentamethyl-4-piperidine) sebacate, bis(1-octyloxy-2 , 2,6,6-tetramethyl-4-piperidinyl) sebacate, 3,5-di-tert-butyl-4-hydroxybenzoic acid-2,4-di-tert-butylphenyl by mass ratio For 1:1:1 stirring and mixing to obtain uniformity.

[0035] The preparation method of antibacterial acrylic plate, it comprises the steps:

[0036] (1) Mix methyl methacrylate and dicumyl peroxide evenly, then heat and polymerize in a water bath at 82°C for 28 minutes, and finally coo...

Embodiment 2

[0041] It is basically the same as Example 1, except that the inorganic antibacterial agent is obtained by uniformly stirring and mixing zinc titanate and zinc molybdate in a mass ratio of 1:1.

Embodiment 3

[0043] It is basically the same as Example 1, except that the inorganic antibacterial agent is obtained by stirring and mixing uniformly zinc stannate and zinc molybdate in a mass ratio of 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com