Cleaning liquid composition used in silicon carbide semiconductor manufacturing process

A technology of cleaning solution and composition, applied in the direction of detergent composition, non-surface active detergent composition, inorganic non-surface active cleaning composition, etc., which can solve the problems of pollution and residue, and achieve the effect of simple raw material components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

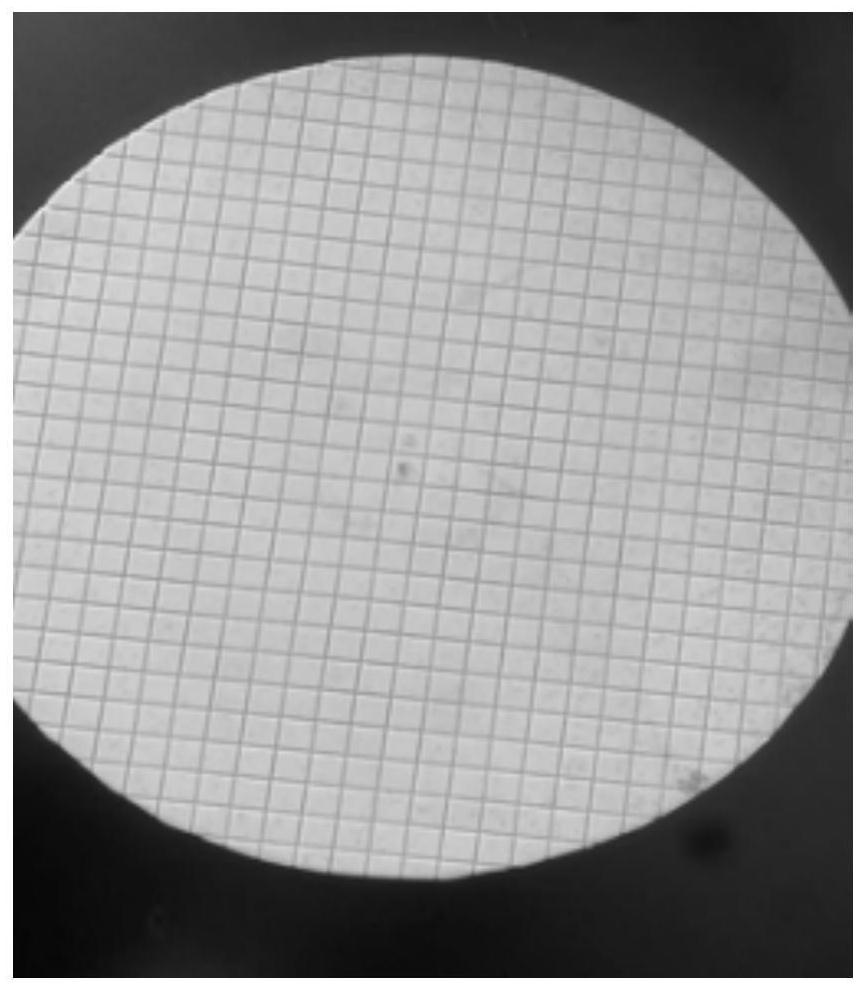

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further elaborated below with reference to the accompanying drawings and specific embodiments.

[0025] The reagents and raw materials used in the present invention are all commercially available.

[0026] 1. Dissolution time test of manganese dioxide by different cleaning solutions

[0027] Table 1 is the distribution ratio of each component in the embodiment of the present invention. According to the formula in the table, each component is uniformly mixed at room temperature, and then shaken and filtered to make the mixing more uniform. In the cleaning liquid composition, each component The sum of the mass fractions is 100%, and the amount of deionized water is calculated as 100% of the sum of the mass fractions of the subsidized components.

[0028] Table 1 Dissolution time of manganese dioxide in different cleaning solutions

[0029]

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com