Aqueous fluorinated polyurethane coating material and preparation method therefor

A water-based polyurethane and polyurethane coating technology, applied in the coating field, can solve the problems of low surface energy, poor water resistance of the coating and high bonding force, and achieve the effects of increasing coating mechanics, excellent hydrophobicity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

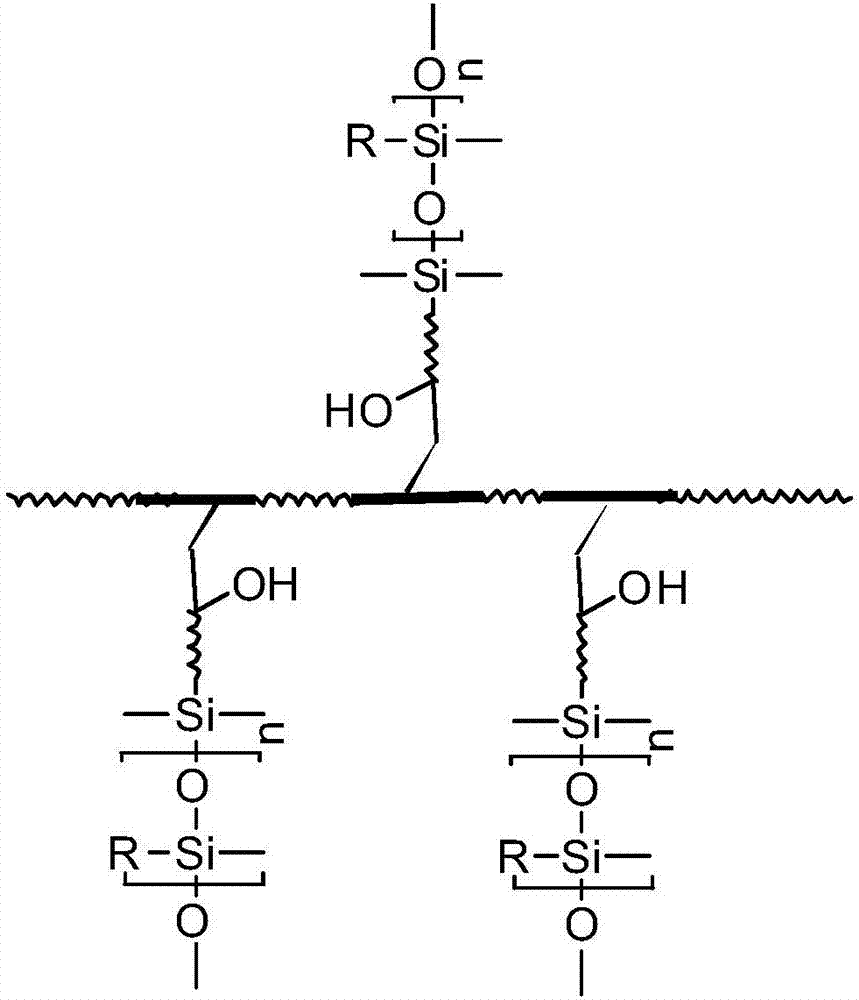

Method used

Image

Examples

Embodiment 1

[0022] (1) Mix 20 parts by volume of absolute ethanol, 0.5 parts by volume of γ-(2,3-epoxypropoxy)propyltrimethoxysilane (KH560), 0.2 parts by volume of heptadecanofluorodecyltriethyl Oxysilane (FAS-17) was mixed uniformly under magnetic stirring, and the pH value was slowly adjusted to about 4 with 15wt% hydrochloric acid, and the epoxy-containing and fluorine-containing silicone sol was obtained after reacting at room temperature for 45 minutes.

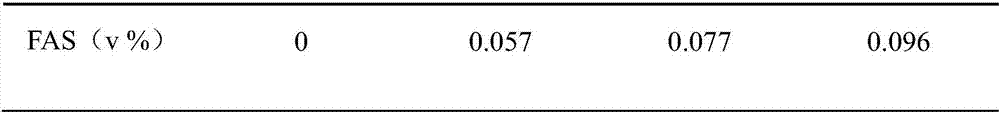

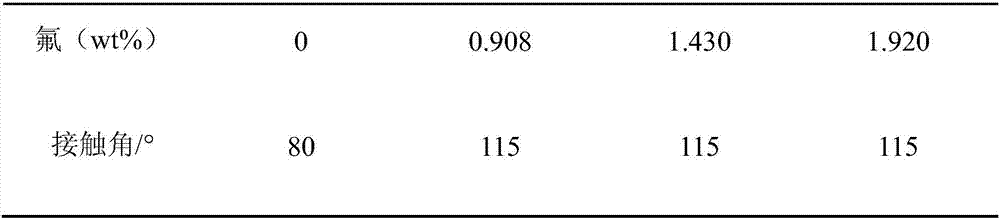

[0023] (2) At room temperature, mix 0.6, 0.8, and 1.0 parts by volume of the above-mentioned sol with 10 parts of WPU (Hefei Anke Fine Chemical Co., Ltd., PU-405C, cationic, solid content 19±1%), and mix them at room temperature. Stir magnetically for 0.5-1 hour to obtain a series of water-based fluorine-containing polyurethane coatings (F-WPU). After dip-coating this series of water-based fluorine-containing polyurethane coatings (F-WPU) on the glass surface, they were cured at 120°C for 20 minutes. The contact angle and fluorine ...

Embodiment 2

[0029] (1) Add 20 parts by volume of absolute ethanol, 0.5 parts by volume of γ-(2,3-epoxypropoxy)propyltriethoxysilane, and 0.3 parts by volume of heptadecafluorodecyltriethoxy The silane (FAS-17) was mixed evenly under magnetic stirring, and the pH was slowly adjusted to about 4 with 15wt% hydrochloric acid, and the fluorine-containing silicone sol was obtained after reacting at room temperature for 45 minutes.

[0030] (2) At room temperature, mix 0.8 parts by volume of the above-mentioned sol with 10 parts of water-based polyurethane emulsion (Hefei Anke Fine Chemical Co., Ltd., PU-405C, solid content 19±1%), and stir magnetically at room temperature for 0.5 to 1 hour, A waterborne fluorine-containing polyurethane coating (F-WPU) was obtained. Dip coating and drying are the same as in Example 1. After testing, the surface properties of the coating are similar to Example 1.

Embodiment 3

[0032] (1) 20 parts by volume of absolute ethanol, 0.5 parts by volume of γ-(2,3-epoxypropoxy)propyltrimethoxysilane (KH560), 0.3 parts by volume of tridecafluorooctyl triethyl The oxysilane was mixed evenly under magnetic stirring, and the pH was slowly adjusted to about 4 with 15 wt% hydrochloric acid, and the fluorine-containing silicone sol was obtained after reacting at room temperature for 45 minutes.

[0033] (2) At room temperature, mix 4 parts by volume of the above-mentioned sol with 10 parts of water-based polyurethane emulsion (Hefei Anke Fine Chemical Co., Ltd., PU-405C, solid content 19±1%), and stir magnetically at room temperature for 0.5 to 1 hour, A waterborne fluorine-containing polyurethane coating (F-WPU) was obtained. Dip coating and drying are the same as in Example 1. After testing, the surface properties of the coating are similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com