Circulating fluidized bed coal gasification multi-stage cooling and dedusting process and device

A circulating fluidized bed and coal gasification technology, which is applied in the field of coal gasification, can solve the problems of high consumption, low filtration speed, and difficulty in cleaning dust, and achieve the effects of increasing calorific value, high heat exchange efficiency, and avoiding explosion accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

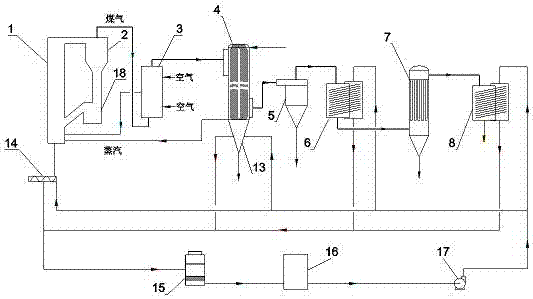

[0043] Such as figure 1 shown. The working process of this embodiment: the raw coal is added to the circulating fluidized bed gasifier 1 for reaction, the mixture of high-temperature coal gas and semi-coke generated by the gasifier 1 is separated from gas and solid by the cyclone separator 2, and the high-temperature circulating semi-coke is separated by the cyclone The feeder 18 at the bottom of the gasifier 2 directly returns to the gasifier 1 to mix and react with the raw coal to generate volatile matter and semi-coke; the volatile matter rises to the upper part of the furnace and becomes a part of the gas, and the coarser particles sink to the bottom of the furnace to be mixed with the high temperature Air and steam undergo combustion and gasification reactions; finer semi-coke particles rise to the upper part of the furnace, absorb heat from the bottom, and undergo gasification reactions with carbon dioxide and steam to generate coal gas.

[0044] The slag discharged fro...

Embodiment 2

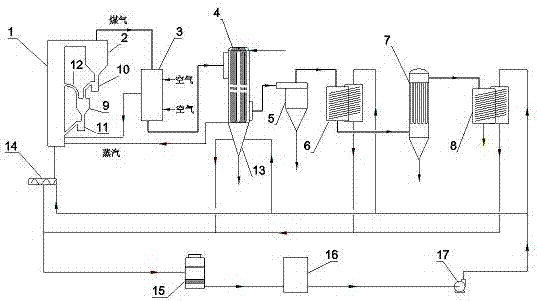

[0051] like figure 2 shown. The working process of this embodiment: the raw coal is added to the pyrolysis furnace 9, and the high-temperature circulating semi-coke obtained after gas-solid separation in the cyclone separator 2 is added to the pyrolysis furnace 9 through the return device 10 at the bottom of the cyclone separator; The high-temperature circulating semi-coke is mixed and reacted in the pyrolysis furnace 9 to produce pyrolysis gas and pyrolysis semi-coke; the pyrolysis gas is discharged from the connecting pipe 12 at the top of the pyrolysis furnace 9 and passed into the dilute phase area of the gasifier 1, The pyrolysis semi-coke and solid heat carrier enter the gasification furnace 1 through the pyrolysis furnace feeder 11, and undergo combustion and gasification reactions with high-temperature air and steam; the finer semi-coke particles rise to the upper part of the furnace, absorb heat from the bottom and Gasification reaction occurs with carbon dioxide ...

Embodiment 3

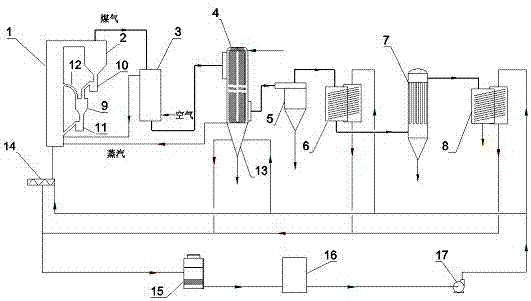

[0059] like image 3 shown. The working process of this embodiment is the same as that of Embodiment 2, the difference lies in the flow directions of gas and air in the tube-and-tube heat exchanger 3 .

[0060] In this embodiment, the high-temperature coal gas exiting the gasifier 1 is separated by the cyclone separator 2 and enters the tube side from the top of the tube heat exchanger 3, and the gas is discharged from the tube side from the bottom of the tube heat exchanger 3 after heat exchange; The lower part of the tube-and-tube heat exchanger 3 enters the shell side for heat exchange, passes through multiple baffles and turns back, and after heating up, the upper part of the tube-and-tube heat exchanger 3 exits the shell side and enters the bottom of the gasifier 1 for gasification.

[0061] The gasification furnace 1 adopts a hood to distribute air, and the working temperature at the bottom of the furnace is 1000°C, and the working temperature at the top is 945°C; the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com