Electric motor, especially pump motor

An electric motor and pump motor technology, applied in the field of pump motors, can solve problems such as damage to welded joints, and achieve the effects of fewer parts, firm connection, and economical manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

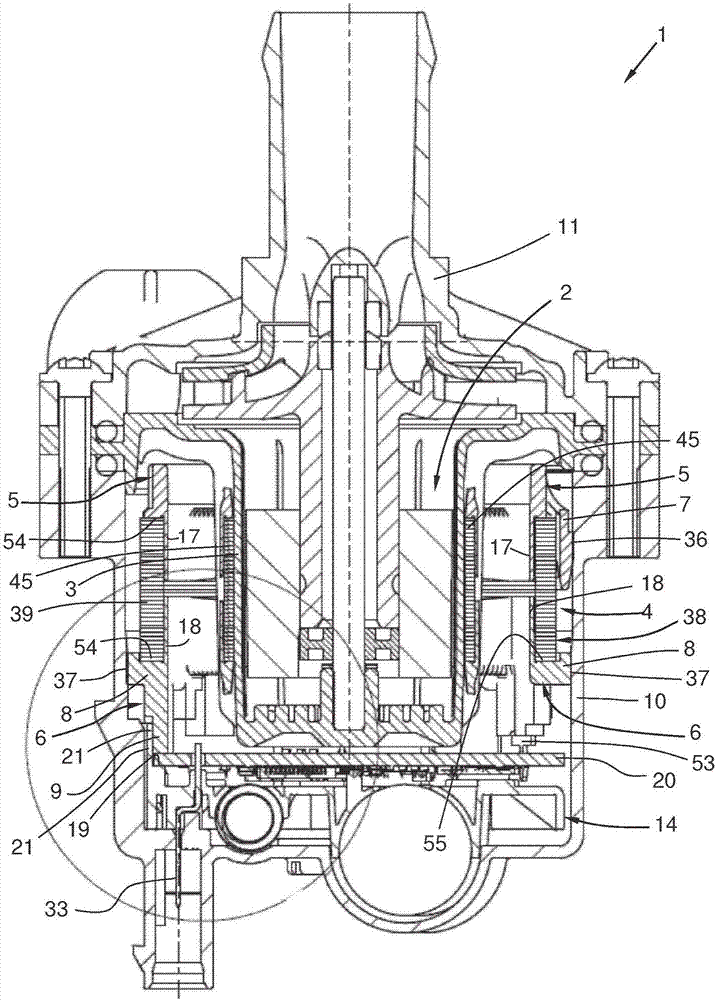

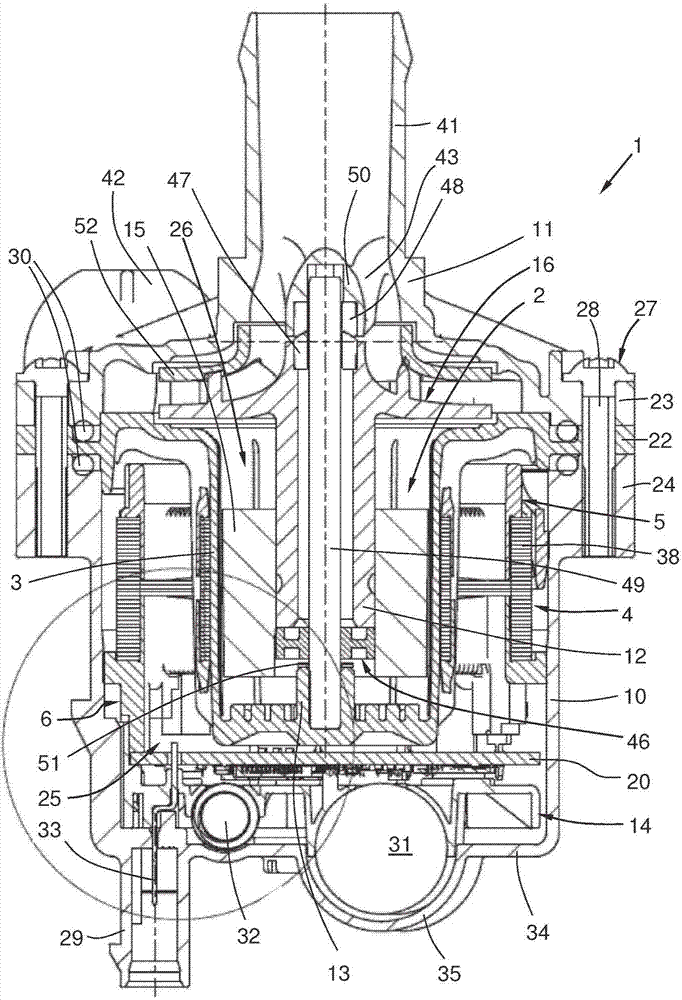

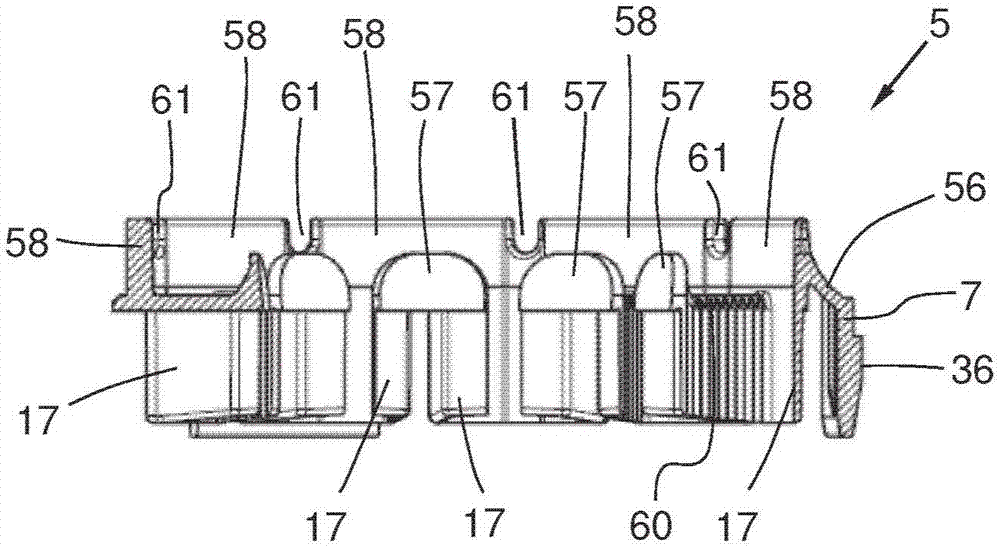

[0031] figure 1 A sectional view of an electric motor 1 according to the invention is shown with a wound stator 4 , a permanent magnet rotor 2 , an insulating pot 3 , a pump head 11 , a circuit board 20 , a carrier plate 14 and a motor housing 10 . The stator 4, circuit board 20 and carrier board 14 are located in a dry chamber 25 (see figure 2 ). The permanent magnet rotor 2 is supported in the wet chamber 26 in a rotatable manner around an axis 49 (see figure 2 ), the axis is fixedly installed in the isolation tank 3 on one side, and fixedly installed in the pump head 11 on the other side. The stator 4 comprises a stator lamination stack 38 and an insulating element 6 . Stator winding 40 (see Figure 8 and Figure 9 ) is not shown here. The stator lamination pack 38 comprises a closed return ring (Rückschlussring) 39 with radially inwardly extending poles 45 which alternate with the slots into which the slot-lined regions 17, 18 of the insulating elements 5, 6 are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com