Wet flue gas desulfurization device and method of operating wet flue gas desulfurization device

A technology of desulfurization device and operation method, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as the inability of absorbing liquid to maintain drainage treatment standards, nozzle blockage, and solid-liquid separator blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

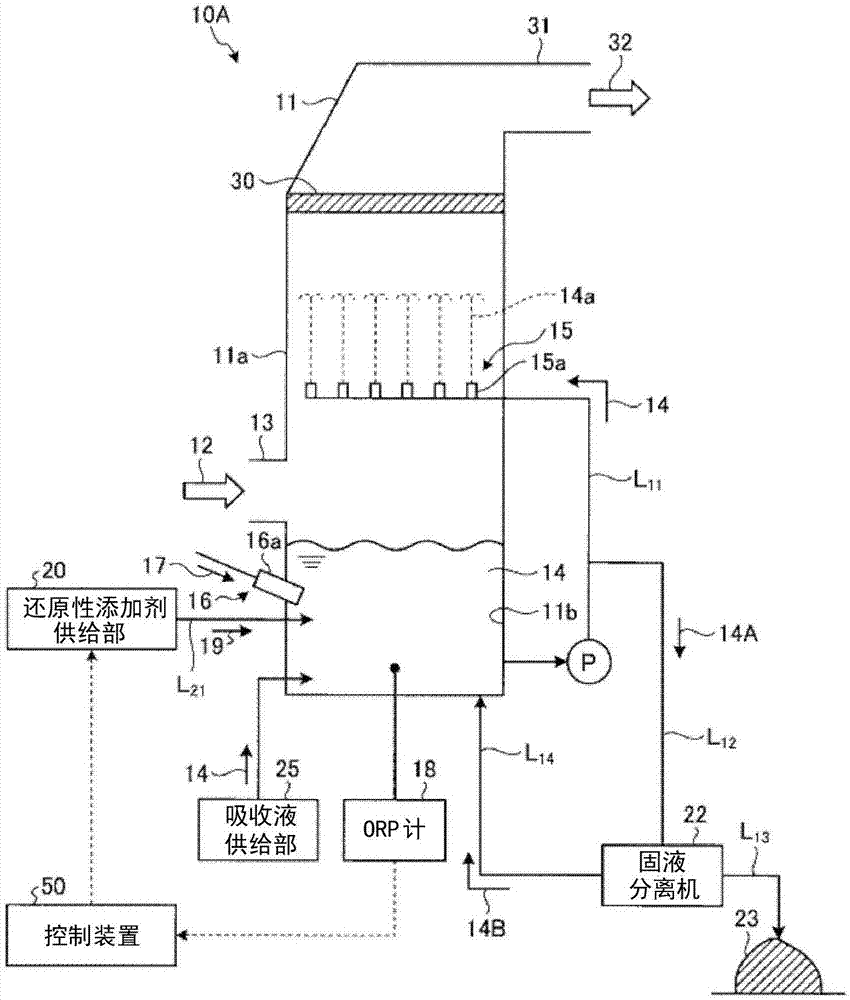

[0051] The wet flue gas desulfurization device according to the first embodiment of the present invention will be described with reference to the accompanying drawings. figure 1 It is a schematic diagram showing the wet flue gas desulfurization apparatus according to Example 1. like figure 1 As shown, a wet flue gas desulfurization device (hereinafter referred to as a "desulfurization device") 10A according to the present embodiment is provided with a gas (hereinafter referred to as "exhaust gas") 12 that removes a gas discharged from a boiler (not shown) with an absorbing liquid 14 The absorption tower 11 of sulfur oxides in the absorption tower 11; the gas introduction part 13 which is installed on the side wall 11a of the absorption tower 11 and introduces the exhaust gas 12; The absorption liquid storage part 11b of the absorption liquid 14; the circulation line L that circulates the absorption liquid 14 from the absorption liquid storage part 11b 11 ; set in the vicinit...

Embodiment 2

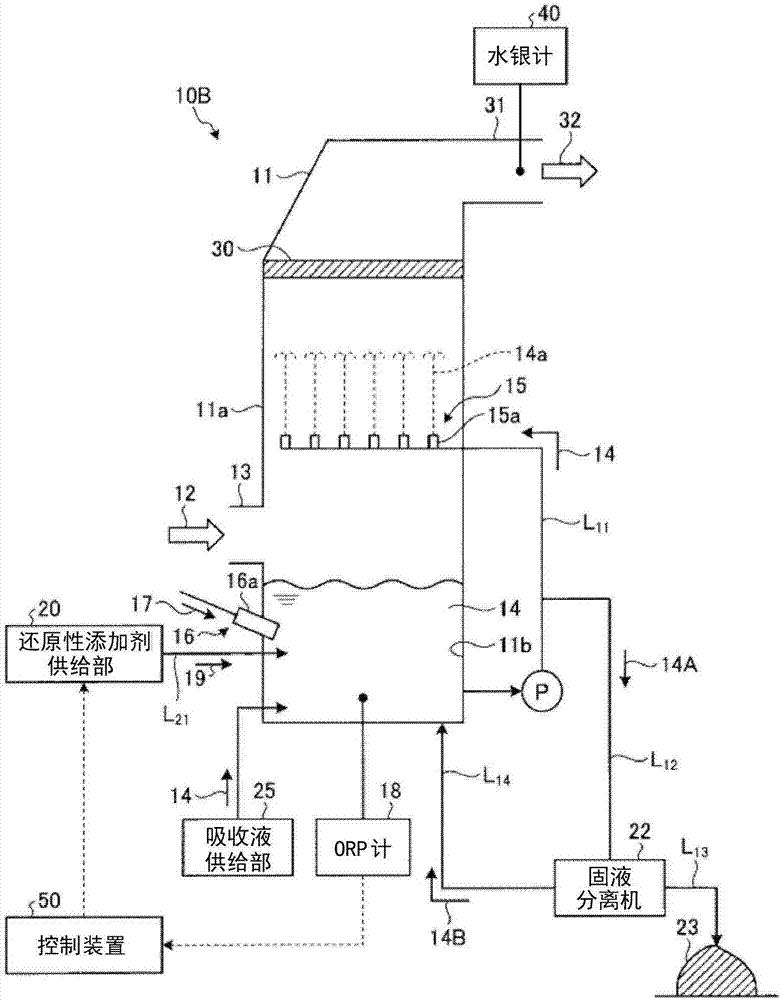

[0125] The wet flue gas desulfurization device according to the second embodiment of the present invention will be described with reference to the accompanying drawings. image 3 It is a schematic diagram showing the wet flue gas desulfurization device according to this embodiment. In addition, the same code|symbol is attached|subjected to the same member as Example 1, and the description is abbreviate|omitted.

[0126] like image 3 As shown, in the desulfurization apparatus 10B according to the present embodiment, in the desulfurization apparatus 10A of the first embodiment, the mercury meter 40 is provided in the vicinity of the exhaust duct 31 from which the purified gas 32 is discharged. In addition, when the reducing additive 19 of sulfur oxo acid system such as sodium thiosulfate is supplied as in Example 1, and the ORP based on the ORP meter 18 is adjusted to an appropriate range, the mercury meter 40 measures from the absorption tower 11 Mercury concentration in the...

Embodiment 3

[0131] The wet flue gas desulfurization device according to Example 3 of the present invention will be described with reference to the accompanying drawings. Figure 4 It is a schematic diagram showing the wet flue gas desulfurization device according to this embodiment. In addition, the same code|symbol is attached|subjected to the same member as Example 1, and the description is abbreviate|omitted.

[0132] like Figure 4 As shown, the desulfurization apparatus 10C according to the present embodiment includes the desulfurization apparatus 10A of the first embodiment, and further includes an oxidative additive supply unit 52 that supplies an oxidative additive 51 in the absorption liquid 14 or the absorption liquid storage section 11b, and supplies sulfur. As a result of the oxoacid-based reducing additive 19 , when the ORP measured by the ORP meter 18 is less than 50 mV, the oxidative additive 51 is supplied from the oxidative additive supply unit 52 . This operation contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com