Ion Beam Polishing Machine for Reducing Short Circuit Frequency of Tungsten Wire

An ion beam and polishing machine technology, which is applied in the field of ion beam polishing, can solve the problems that the ion beam polishing machine cannot keep working normally for a long time, the ion beam polishing machine reduces the cleaning frequency, etc., so as to improve the normal working time and flexibly adjust the thickness. , the effect of reducing the frequency of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

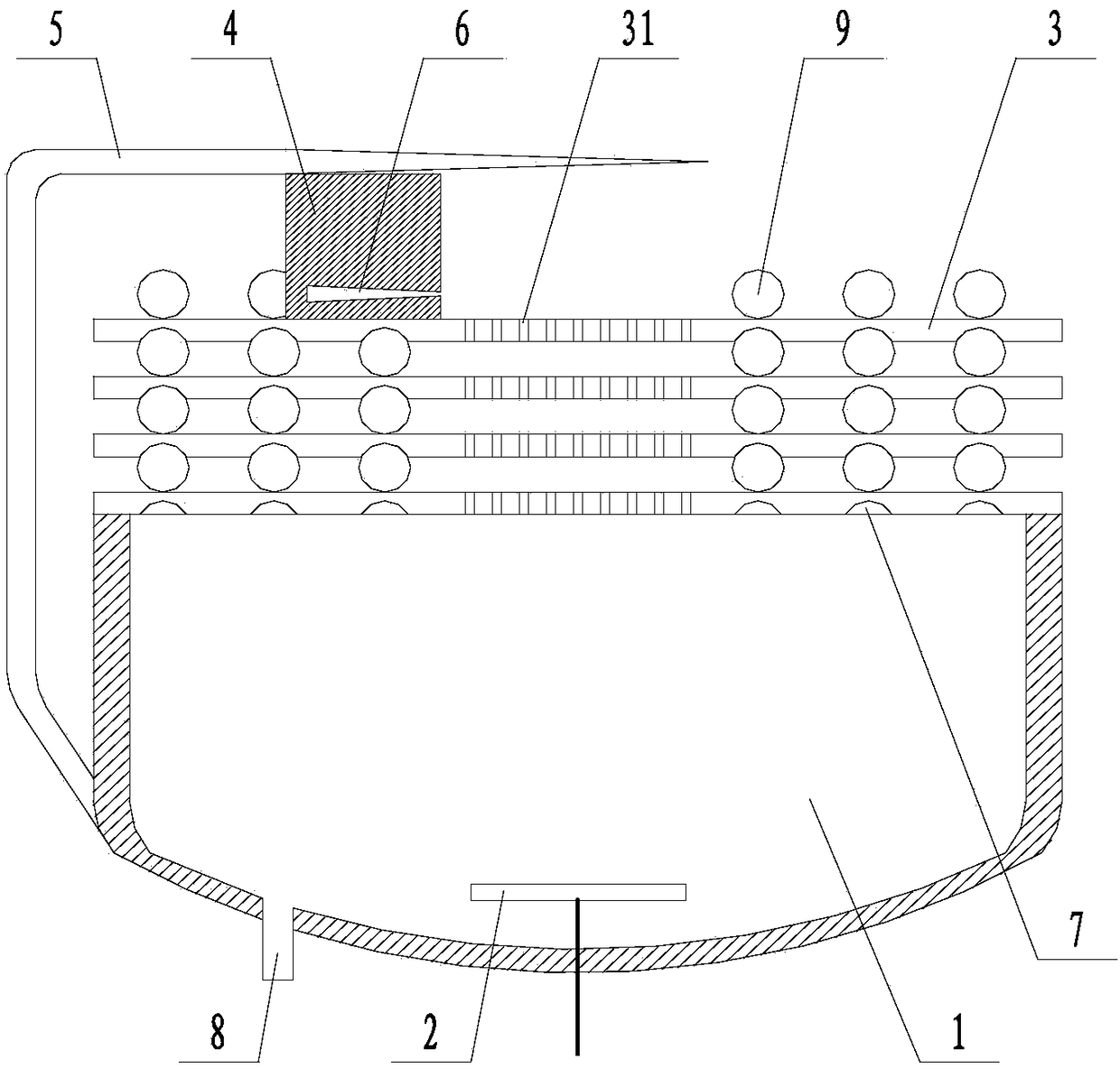

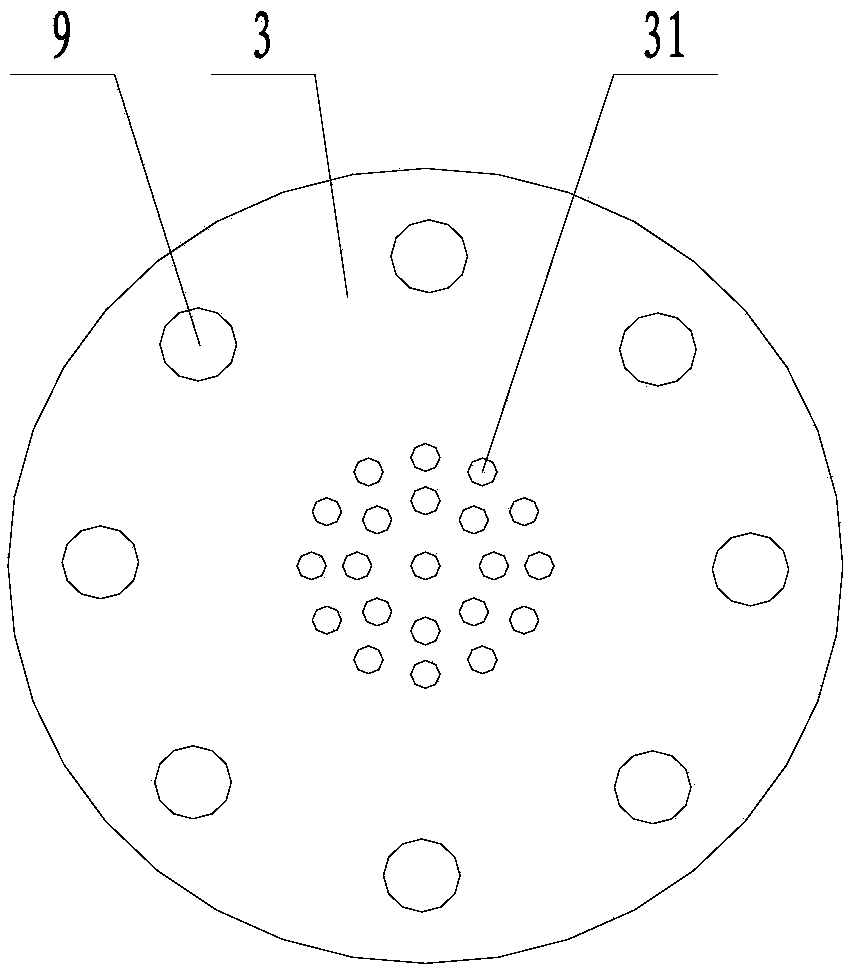

[0023] Such as figure 1 and figure 2 The shown ion beam polishing machine for reducing the short-circuit frequency of tungsten wires includes a discharge chamber 1, an anode plate 2 located in the discharge chamber 1, and several layers of grid plates 3 arranged at the outlet end of the discharge chamber 1, and the outermost grid plate 3 is provided with a mounting block 4, the mounting block 4 is provided with a tungsten wire 5, one end of the tungsten wire 5 protrudes to the outside of the mounting block 4, and a number of ceramic balls 9 are fixedly connected to the top surface of the grid plate 3. A plurality of first grooves 7 are arranged on the bottom surface of the grid plate 3, the surface of the first grooves 7 is a spherical surface with the same radius as the ceramic ball 9, and the longitudinal section of the first grooves 7 is a minor arc; The ceramic balls 9 on the top surface of the grid plate 3 and the first groove 7 on the bottom surface of the grid plate 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com