Toner resin for copying machine and preparation method of yellow toner

A technology for toner and copiers, applied in developer, electrography, optics, etc., can solve problems such as unstable color density, difficult charge control, pollution, etc., and achieve stable printing durability and good image quality of printed products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

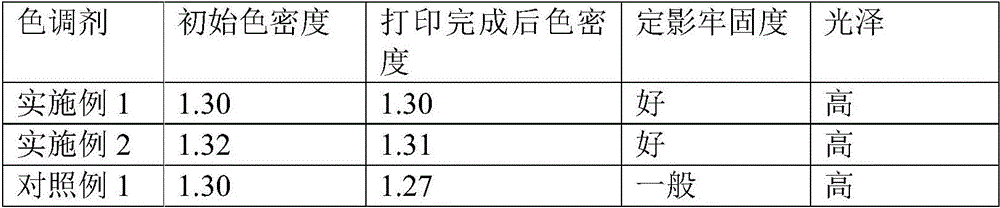

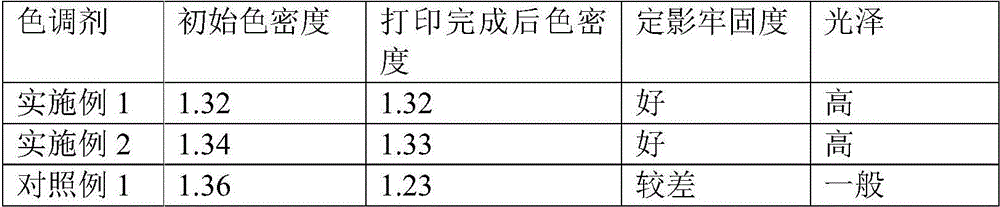

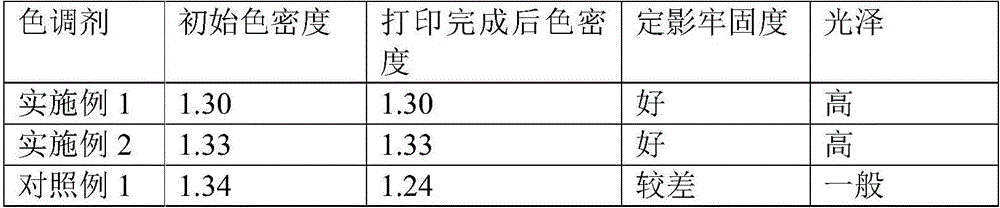

Examples

preparation example Construction

[0042]According to an embodiment of the present invention, a method for preparing a yellow toner is provided, wherein the yellow toner includes the following raw materials in parts by weight: styrene-n-butyl acrylate polymer 100, colorant 5-20, vapor phase Silicon dioxide 0.25-0.75, release agent 0-10 and / or charge control agent 0-10; the colorant includes at least one of the following: yellow iron oxide, benzidine yellow, Hansa yellow, chrome yellow, benzo Imidazolone yellow, quinacridone yellow, carbon black, ferric oxide, preferably quinacridone yellow.

[0043] In addition, for the above-mentioned yellow toner, wherein, the release agent includes at least one of the following: paraffin wax, palm wax, beeswax, montan wax, Fischer-Tropsch wax, ester wax; preferably palm wax, ester wax; more preferably palm wax Wax; the charge control agent includes at least one of the following: salicylic acid metal complexes, azo metal complexes, diphenylglycolic acid boron complexes, macro...

Embodiment 1

[0053] Preparation of toner weight ratio composition:

[0054] Styrene-n-butyl acrylate resin: 100 parts (Mw=110000, Mn=4000, Mp1=3000, Mp2=130000, Tg=50°C, Tsp=90°C);

[0055] Colorant: 8 parts (Pigment Yellow PY180 from UNION Company);

[0056] Release agent: 1 part (carnauba wax T3);

[0057] Charge control agent: 1.2 parts (E-84 of Japan Oriental Chemical Company);

[0058] Fumed silica: 0.3 parts (EVONIK R812);

[0059] Fumed silica: 0.6 parts (EVONIK R972).

Embodiment 2

[0061] Preparation of toner weight ratio composition:

[0062] Styrene-n-butyl acrylate resin: 100 parts (Mw=90000, Mn=3000, Mp1=2000, Mp2=110000, Tg=45°C, Tsp=85°C);

[0063] Colorant: 8 parts (Pigment Yellow PY180 from UNION Company);

[0064] Iron tetroxide: 1 part (TB5625 of Huntsman, used to enhance coloring);

[0065] Release agent: 2 parts (carnauba wax T3);

[0066] Charge control agent: 0.8 parts (E-84 of Japan Oriental Chemical Company);

[0067] Fumed silica: 0.25 parts (EVONIK R812);

[0068] Fumed silica: 0.75 parts (EVONIK R972).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com