Recycling method and equipment of waste red gypsum of titanium white factory

A titanium dioxide factory, red gypsum technology, applied in the direction of titanium compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of troublesome processing, increase of chemical reagents, complex production process, etc., to achieve resource saving, simple process steps, high granularity even size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

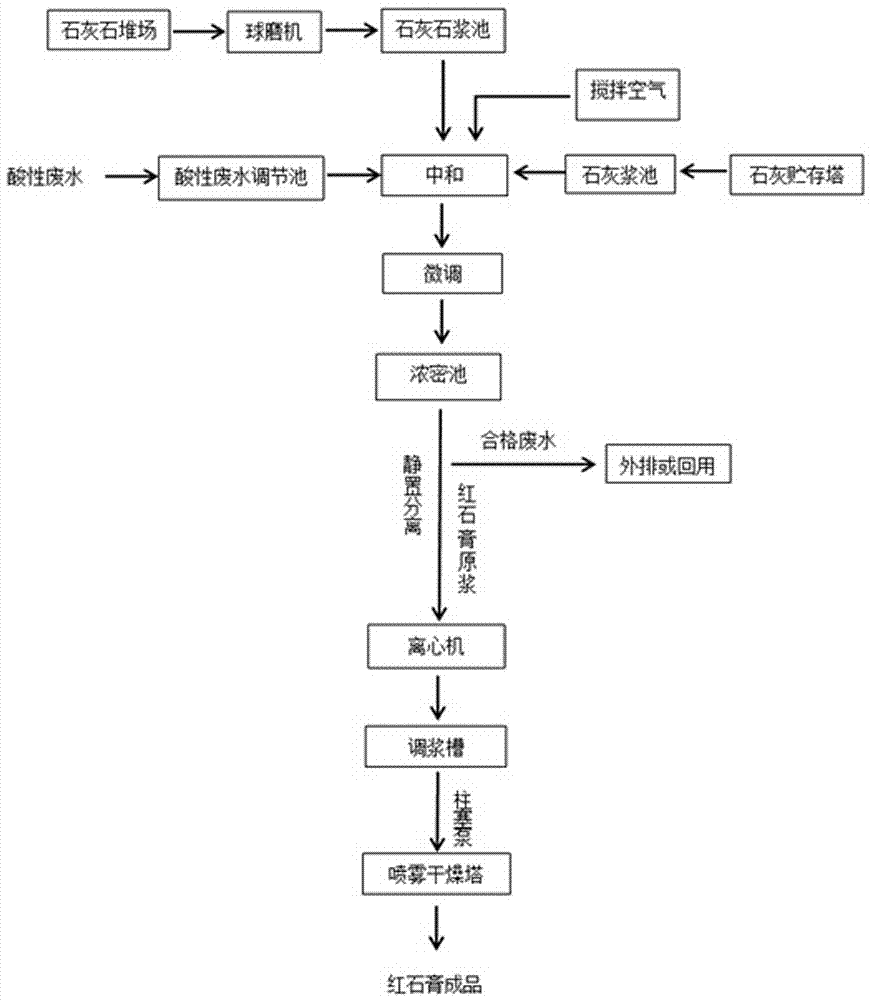

[0032] A method for recycling red gypsum, which is waste from a titanium dioxide factory, processes acid waste water produced in the process of producing titanium dioxide by a sulfuric acid method, and recycles red gypsum; specifically comprises the following steps:

[0033] (1) In the process of producing titanium dioxide by the sulfuric acid method, the ilmenite and concentrated sulfuric acid are subjected to acidolysis reaction and separated to obtain titanyl sulfate, which is hydrolyzed to generate metatitanic acid, and then press-filtered to obtain solid metatitania Acid and acid wastewater;

[0034] (2) Add 50-mesh limestone to the acid wastewater, neutralize the pH value of the solution to 3, then add lime water to neutralize the pH value of the solution to 6, use a pump to pump the solution into the dense pool, stand for separation, and obtain sludge slurry and sewage;

[0035] (3) After the sewage has passed the inspection, it is directly discharged or reused, and th...

Embodiment 2

[0041] A method for recycling red gypsum, which is waste from a titanium dioxide factory, processes acid waste water produced in the process of producing titanium dioxide by a sulfuric acid method, and recycles red gypsum; specifically comprises the following steps:

[0042] (1) In the process of producing titanium dioxide by the sulfuric acid method, the ilmenite and concentrated sulfuric acid are subjected to acidolysis reaction and separated to obtain titanyl sulfate, which is hydrolyzed to generate metatitanic acid, and then press-filtered to obtain solid metatitania Acid and acid wastewater;

[0043] (2) Add 100-mesh limestone to the acidic wastewater, neutralize the pH value of the solution to 3-4, then add lime water to neutralize the pH value of the solution to 6-9, use a pump to pump the solution into the dense pool, and let it stand for separation , to obtain sludge and sewage;

[0044] (3) After the sewage has passed the inspection, it is directly discharged or reu...

Embodiment 3

[0050] A method for recycling red gypsum, which is waste from a titanium dioxide factory, processes acid waste water produced in the process of producing titanium dioxide by a sulfuric acid method, and recycles red gypsum; specifically comprises the following steps:

[0051] (1) In the process of producing titanium dioxide by the sulfuric acid method, the ilmenite purchased from the mine is put into the reaction kettle, and concentrated sulfuric acid with a mass concentration of 98% is added, and water is added to initiate the reaction to obtain the product; cooling, filtering Remove the dust and ore to obtain titanium liquid; put the titanium liquid into the vacuum refrigerated centrifuge, and then adjust the vacuum degree of the vacuum refrigerated separator, ferrous sulfate crystallizes, and centrifuges to obtain ferrous sulfate heptahydrate crystals and titanyl sulfate; Lead titanyl sulfate into the hydrolysis tank through the pipeline, boil at the hydrolysis temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com