A lead-free low loss high energy storage density ceramic material and its preparation method

A technology of high energy storage density and ceramic material, applied in the field of lead-free, low loss, high energy storage density ceramic materials and their preparation, which can solve the problems of low energy storage density, limited application, low saturation polarization and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

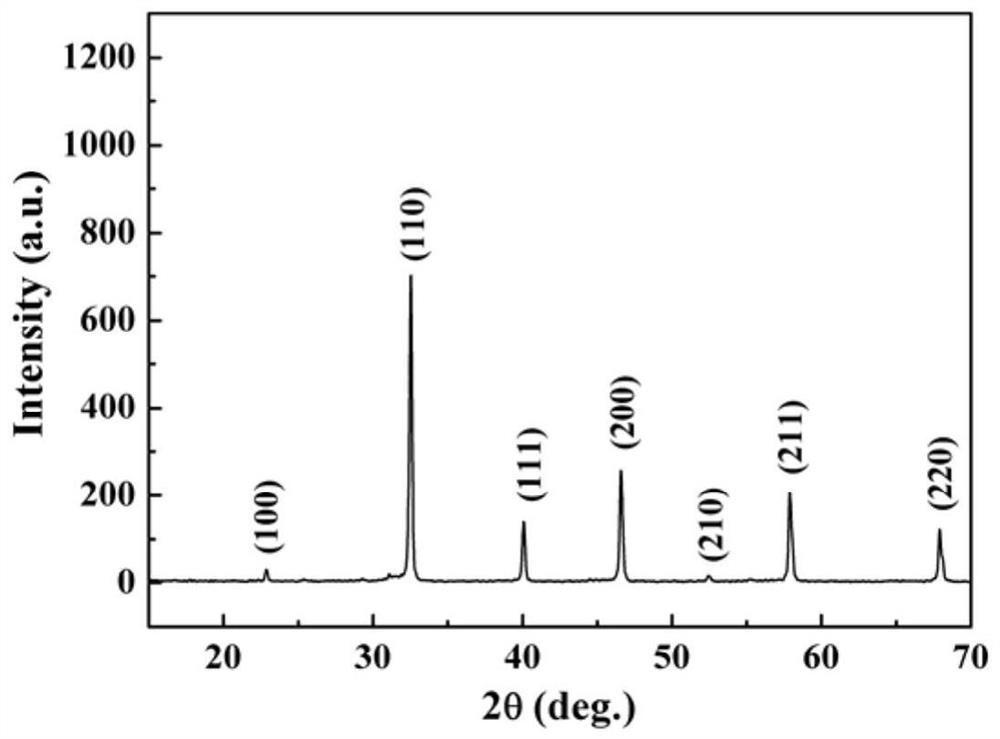

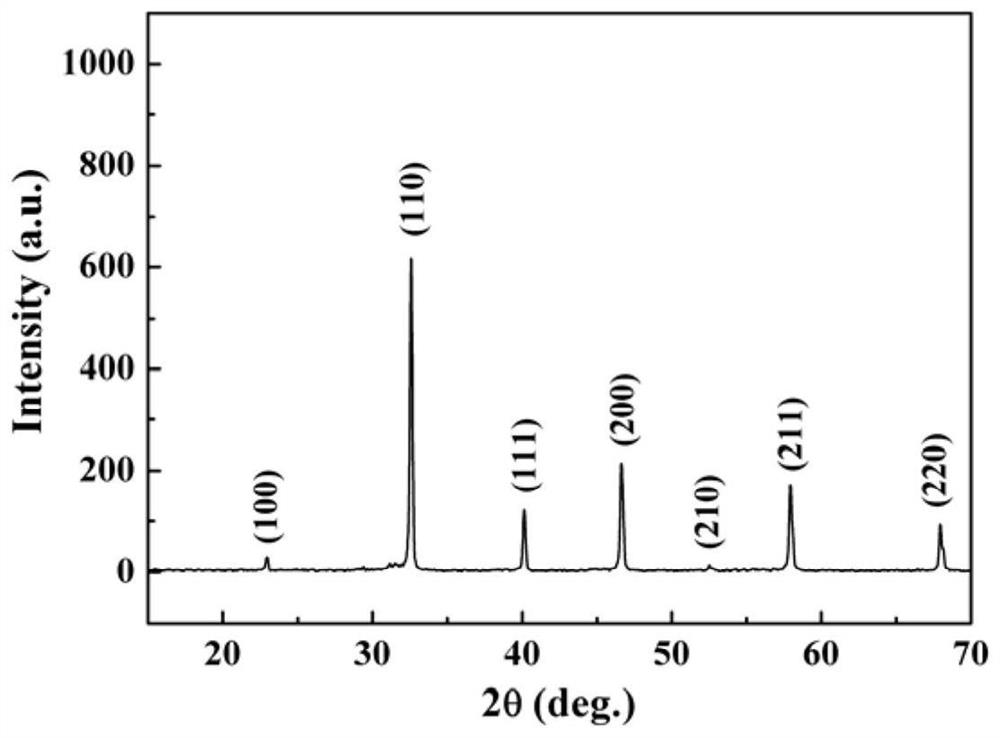

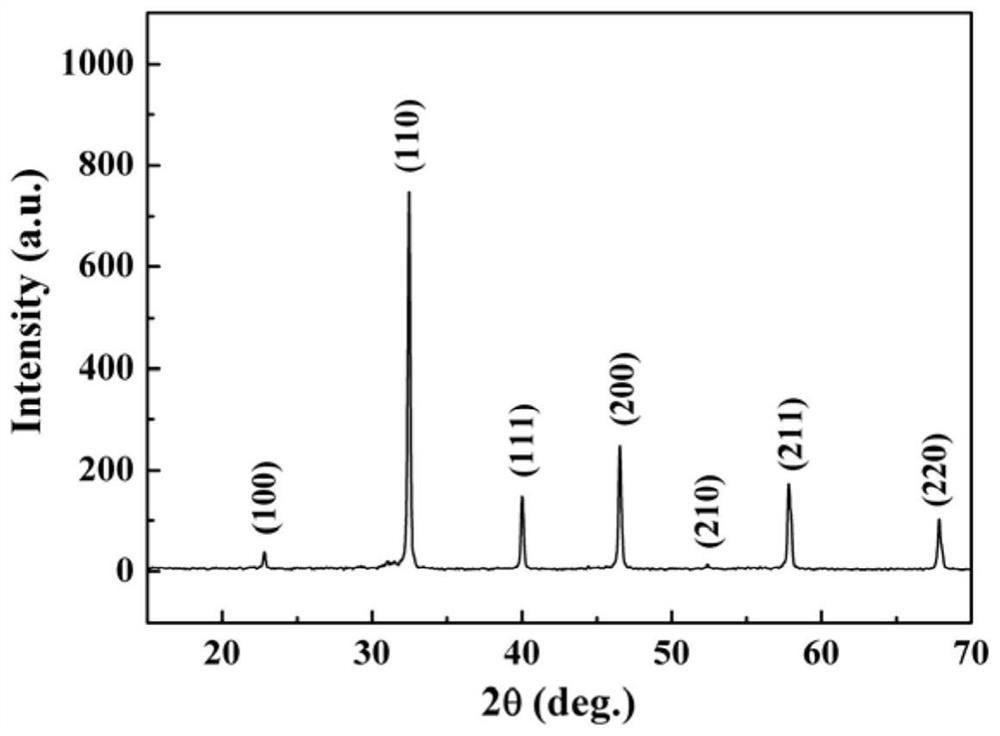

Image

Examples

preparation example Construction

[0055] The preparation method of the lead-free low loss high energy storage density ceramic material of the present invention comprises the following steps:

[0056] (1) According to the chemical formula SrTiO 3 will analyze pure SrCO 3 and TiO 2 Carry out ingredients and mix evenly, then sieve, briquette, and then pre-fire at 1150-1200°C for 3-5 hours to obtain a block solid, then crush the block solid and pass through a 120-mesh sieve to obtain SrTiO 3 Powder;

[0057] (2) According to the chemical formula 0.95Bi 0.5 Na 0.5 TiO 3 -0.05BaAl 0.5 Nb 0.5 o 3 Bi 2 o 3 、Na 2 CO 3 、TiO 2 、BaCO 3 、Al 2 o 3 and Nb 2 o 5 Perform batching and mixing evenly, then sieve, briquette, and then pre-fire at 850-900°C for 3-4 hours to obtain block solids, then crush the block solids and sieve to obtain 0.95Bi 0.5 Na 0.5 TiO 3 -0.05BaAl 0.5 Nb 0.5 o 3 Powder;

[0058] (3) the SrTiO in step (1) 3 Powder and 0.95Bi in step (2) 0.5 Na 0.5 TiO 3 -0.05BaAl 0.5 Nb 0.5 o...

Embodiment 1

[0069] The chemical formula of lead-free low loss high energy storage density ceramic material is: (1-x)SrTiO 3 -x(0.95Bi 0.5 Na 0.5 TiO 3 -0.05BaAl 0.5 Nb 0.5 o 3 ), where x represents 0.95Bi 0.5 Na 0.5 TiO 3 -0.05BaAl 0.5 Nb 0.5 o 3 Mole fraction, and x=0.1.

[0070] The preparation method of the above-mentioned lead-free low loss high energy storage density ceramic material comprises the following steps:

[0071] (1) According to the chemical formula SrTiO 3 will analyze pure SrCO 3 and TiO 2 Carry out ingredients and mix evenly, then sieve, briquette, and then pre-fire at 1150°C for 5 hours to obtain a block solid, then crush the block solid and pass through a 120-mesh sieve to obtain SrTiO 3 Powder;

[0072] (2) According to the chemical formula 0.95Bi 0.5 Na 0.5TiO 3 -0.05BaAl 0.5 Nb 0.5 o 3 Bi 2 o 3 、Na 2 CO 3 、TiO 2 、BaCO 3 、Al 2 o 3 and Nb 2 o 5 Carry out ingredients and mix evenly, then sieve, briquette, and then pre-fire at 900°C for ...

Embodiment 2

[0080] The chemical formula of lead-free low loss high energy storage density ceramic material is: (1-x)SrTiO 3 -x(0.95Bi 0.5 Na 0.5 TiO 3 -0.05BaAl 0.5 Nb 0.5 o 3 ), where x represents 0.95Bi 0.5 Na 0.5 TiO 3 -0.05BaAl 0.5 Nb 0.5 o 3 Mole fraction, and x=0.2.

[0081] The preparation method of the above-mentioned lead-free low loss high energy storage density ceramic material comprises the following steps:

[0082] (1) According to the chemical formula SrTiO 3 will analyze pure SrCO 3 and TiO 2 Carry out ingredients and mix evenly, then sieve, briquette, and then pre-fire at 1160°C for 5 hours to obtain a block solid, then crush the block solid and pass through a 120-mesh sieve to obtain SrTiO 3 Powder;

[0083] (2) According to the chemical formula 0.95Bi 0.5 Na 0.5 TiO 3 -0.05BaAl 0.5 Nb 0.5 o 3 Bi 2 o 3 、Na 2 CO 3 、TiO 2 、BaCO 3 、Al 2 o 3 and Nb 2 o 5 Carry out ingredients and mix evenly, then sieve, briquette, and then pre-fire at 890°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com