Method for electrocatalytic reduction of carbon dioxide

A technology of carbon dioxide and electrocatalysis, applied in chemical instruments and methods, physical/chemical process catalysts, electrodes, etc., can solve the problem that synthesis gas has not been reported, and achieve the effect of minimizing chemical consumption, reducing consumption, and making up for expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for electrocatalytic reduction of carbon dioxide, comprising the steps of:

[0050] 1) Preparation of ZIF-8 material

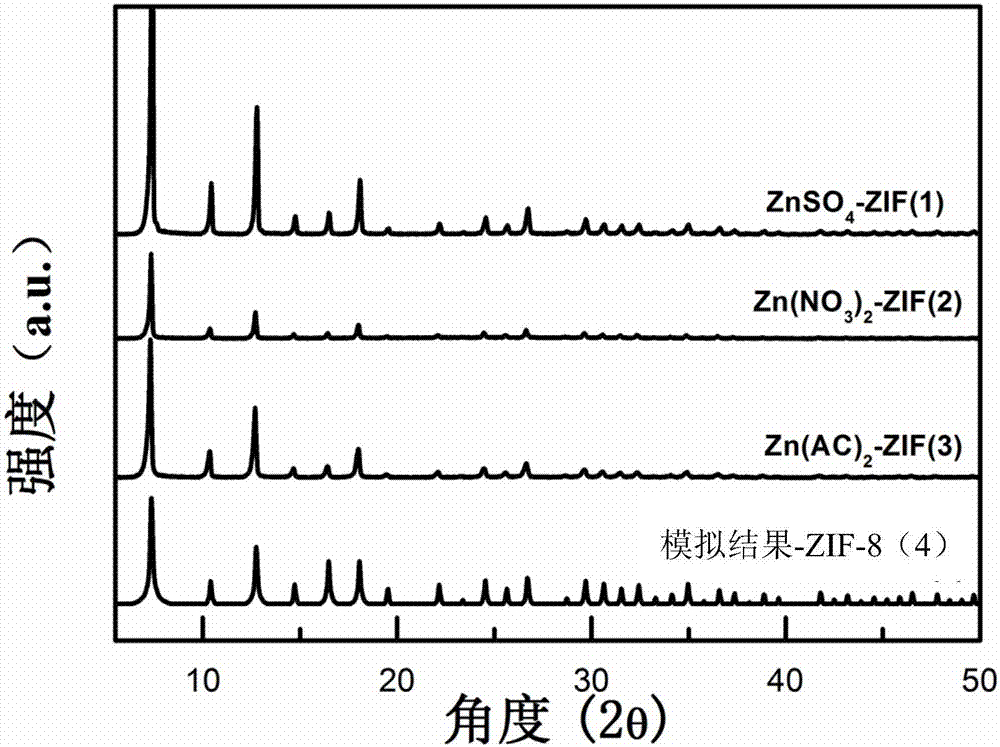

[0051] Under the condition of magnetic stirring at room temperature, 0.558g of zinc sulfate hexahydrate was dissolved in 15ml of anhydrous methanol to form anhydrous clear solution A; 0.616g of organic ligand 2-methylimidazole was dissolved in 15ml of anhydrous methanol to form a clear solution B; Mix the clear solutions A and B, and continue to stir until it becomes turbid to form an emulsion; centrifuge the prepared emulsion at 3500rad / min and wash it 3 to 5 times to obtain a white paste; The paste was dried in a vacuum drying oven at 70°C for 8 hours to obtain a ZIF-8 material. The XRD pattern of the material is as follows figure 1 shown.

[0052] 2) Preparation of electrode-modified glassy carbon electrodes

[0053] Take 10 mg of the ZIF-8 material obtained in step 1), add 1 mg of carbon black, dissolve it in 1 mL of absolute ethanol, an...

Embodiment 2~3

[0057] The impact of using different zinc salts on the results of electrocatalytic carbon dioxide reduction when measuring and preparing ZIF-8 materials, that is, the method steps are the same as in Example 1, the difference is only to change the type of zinc salts in step 1), that is, using Zn(NO 3 ) 2 ·6H 2 O and Zn(AC) 2 ·H 2 O instead of ZnSO in step 1) 4 ·6H 2 O. The XRD pattern of ZIF-8 material is as follows figure 1 The results of the electrocatalytic reduction of carbon dioxide are shown in Table 1.

[0058] Table 1 Electrolysis result detection

[0059]

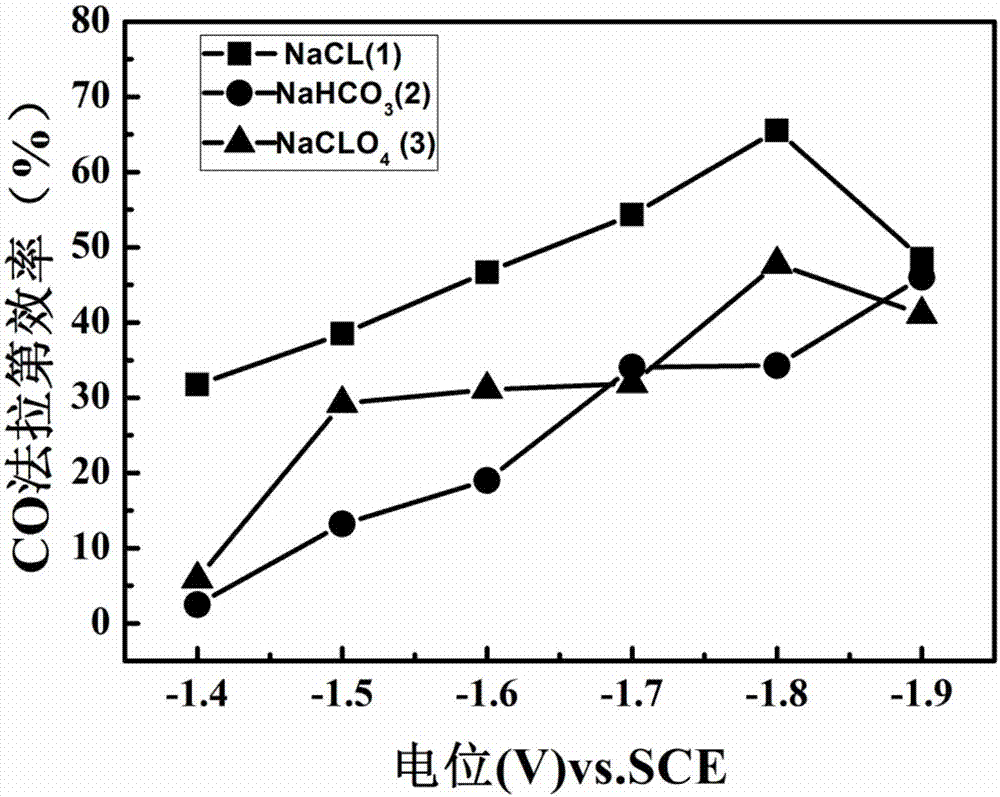

[0060] From Table 1, it can be seen that by adjusting the initial metal source, the CO efficiency and CO / H 2 The effective regulation of the ZIF-8 material prepared from zinc sulfate is used to modify the electrode for electrochemical reduction of CO 2 Tests show that the proportion of CO in the obtained product is higher, and the Faradaic efficiency of CO is higher.

Embodiment 4

[0062] A method for electrocatalytic reduction of carbon dioxide, comprising the steps of:

[0063] 1) Preparation of ZIF-8 material

[0064] Under the condition of magnetic stirring at room temperature, 0.558g of zinc sulfate hexahydrate was dissolved in 15ml of anhydrous methanol to form anhydrous clear solution A; 0.616g of organic ligand 2-methylimidazole was dissolved in 15ml of anhydrous methanol to form a clear solution B; Mix the clear solutions A and B, and continue to stir until it becomes turbid to form an emulsion; centrifuge the prepared emulsion at 3500rad / min and wash it 3 to 5 times to obtain a white paste; The paste was dried in a vacuum oven at 70° C. for 8 hours to obtain the ZIF-8 material.

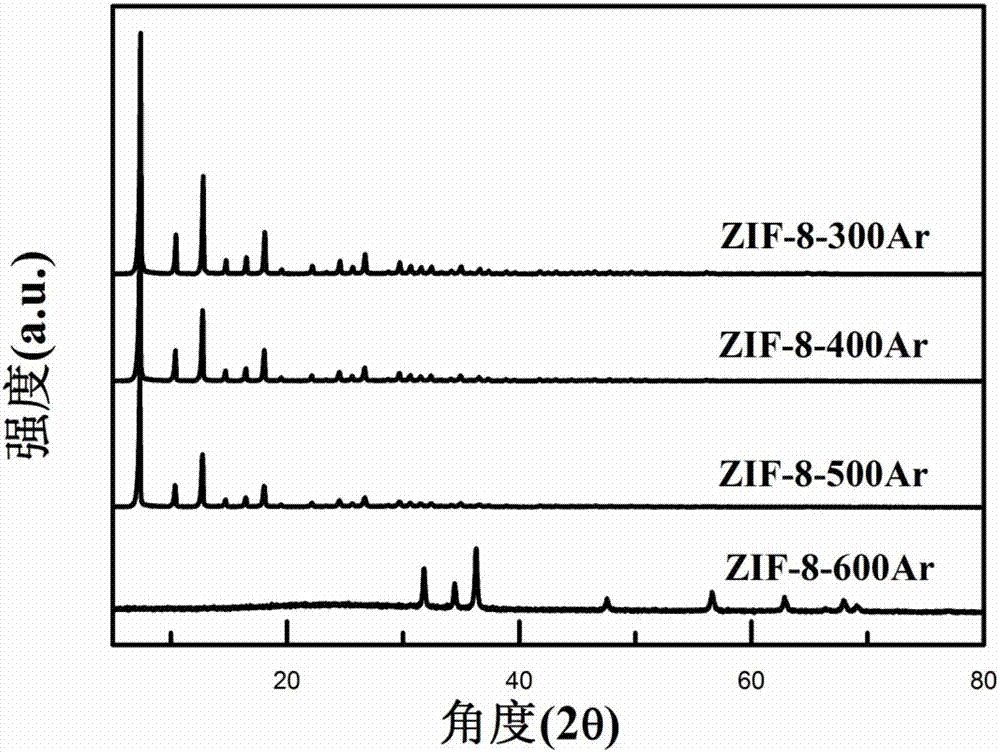

[0065] 2) Preparation of modified ZIF-8 material

[0066] Get 400mg of the ZIF-8 material prepared in step 1) and put it into a tube furnace with an argon atmosphere, keep it warm at 300°C for 2h at a heating rate of 3°C / min, and obtain the modified material after co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com