Electric energy supply system and ceramic isolation layer

A technology of power supply and isolation layer, applied in the direction of circuits, electrical components, battery pack components, etc., can solve problems such as battery short circuit, impact on battery performance, and isolation layer disintegration, etc., to achieve proportional improvement, proper structure and distribution, and improved The effect of electrical capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to clearly disclose the power supply system and its power supply unit disclosed in the present invention, several embodiments will be presented below to describe the technical features of the present invention in detail, and diagrams are also provided to demonstrate these technical features.

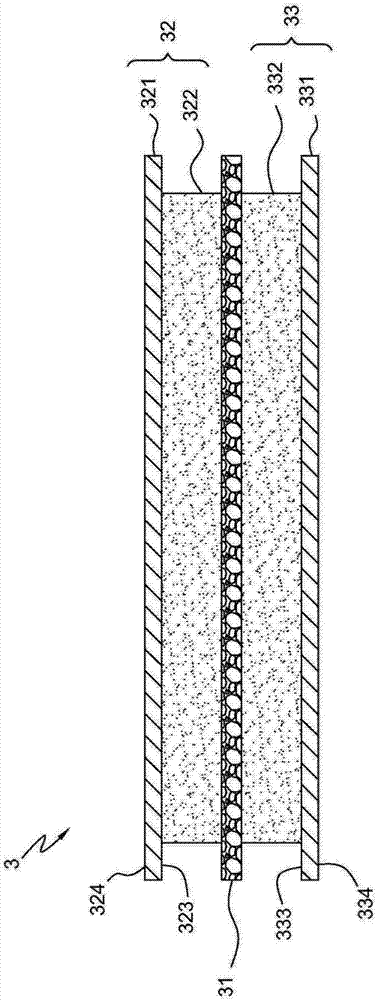

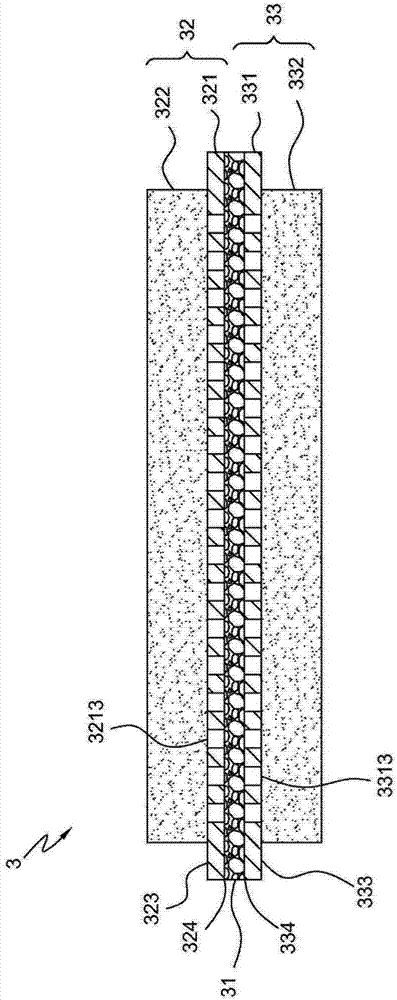

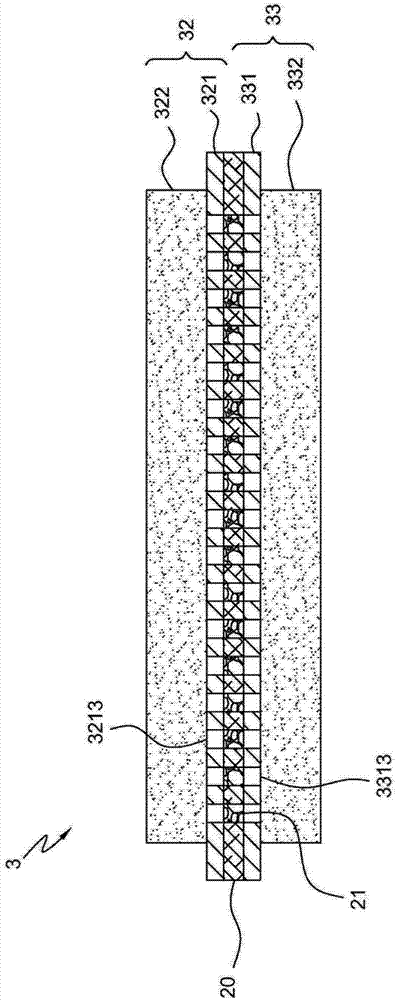

[0058] Please refer to FIG. 1A and FIG. 1B , which are schematic cross-sectional structural views of the power supply unit in a preferred embodiment of the present invention. The power supply unit 3 includes a ceramic isolation layer 31, a first electrode substrate 32, and a second electrode substrate 33, the first electrode substrate 32 includes a first collector layer 321 and a first active material layer 322, and the first collector layer 321 has The first side 323 and the second side 324 are opposite to each other, and the first active material layer 322 is disposed on the first side 323 of the first collector layer 321 . The second electrode substrate 33 includes a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com