Frozen and dried whey cheese melting beans and preparation method thereof

A whey and cheese technology, applied in the field of food processing, can solve the problems of difficult storage and transportation, high water content of whey cheese, and achieve the effects of rich nutritional value and reducing the burden of sewage treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

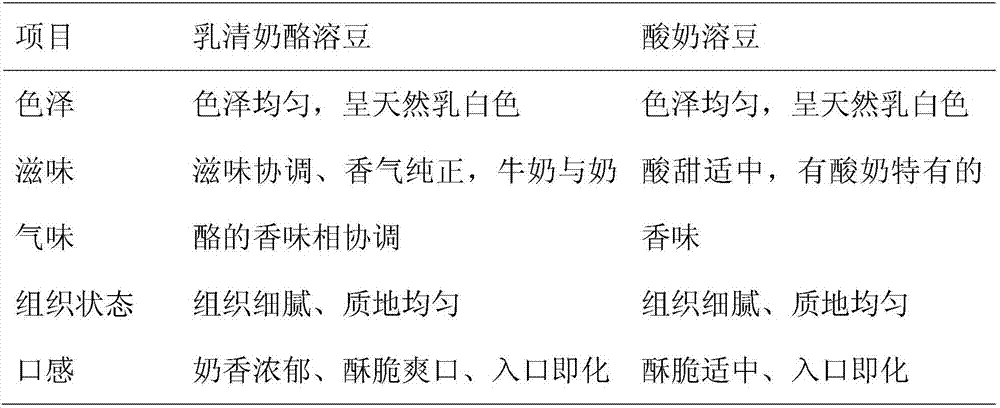

Examples

preparation example Construction

[0029] The preparation method of the above-mentioned freeze-dried whey cheese soluble beans comprises the following steps:

[0030] (1) Coagulate milk with protease, separate casein, discharge buttermilk particles, and obtain whey;

[0031] (2), add white granulated sugar to whey and fully dissolve, obtain whey granulated sugar mixed solution;

[0032] In this step, white granulated sugar is added to the whey, so that the white granulated sugar and whey can be fully fused together, so that the taste of the product is uniform, and the rough taste of the original process is improved;

[0033] (3), heating the whey granulated sugar mixed solution to above 85° C., to obtain the heated whey granulated sugar mixed solution;

[0034] In this step, the purpose of heating is to denature whey protein, induce its self-aggregation and interact with casein to form curd. When the heating temperature is 85°C, the degree of denaturation of whey protein exceeds 90%. The stronger the hydrogen...

Embodiment 1

[0043] Prepare freeze-dried ricotta cheese beans through the following method, specifically comprising the following steps:

[0044] (1) Coagulate milk with protease, separate casein, discharge buttermilk particles, and obtain whey;

[0045] (2), add granulated sugar to whey and fully dissolve, obtain whey granulated sugar mixture;

[0046] (3), heating whey granulated sugar mixed solution to 85 ℃, obtains heated whey granulated sugar mixed solution;

[0047] (4), adding an acidity regulator to the heated whey granulated sugar mixture, adjusting the pH value to 4.0, and now the whey protein contained in the whey is flocculated;

[0048] (5) The mixture flocculated in the separation step 4, wherein the mass ratio of dry matter in the flocculated mixture is 40%;

[0049] (6), add thickener, fruit and vegetable powder to the flocculation mixture in step 5, mix evenly, obtain whey cheese mixture;

[0050] (7) Fill food-grade nitrogen into the whey cheese mixture in step 6, the ...

Embodiment 2

[0054] Prepare freeze-dried ricotta cheese beans through the following method, specifically comprising the following steps:

[0055] (1) Coagulate milk with protease, separate casein, discharge buttermilk particles, and obtain whey;

[0056] (2), add granulated sugar to whey and fully dissolve, obtain whey granulated sugar mixture;

[0057] (3), heating whey granulated sugar mixed solution to 90 ℃, obtains heated whey granulated sugar mixed solution;

[0058] (4), adding an acidity regulator to the heated whey granulated sugar mixture, adjusting the pH value to 5.6, and now the whey protein contained in the whey is flocculated;

[0059] (5), separating the flocculated mixture in step 4, wherein the mass ratio of dry matter in the flocculated mixture is 50%;

[0060] (6), add thickener, sour taste regulator to the flocculation mixture in step 5, mix evenly, obtain whey cheese mixture;

[0061] (7) Fill food-grade nitrogen into the whey cheese mixture in step 6, the volume ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com