Preparation for brewer grain charcoal and application of brewer grain charcoal in lead-bearing wastewater

A technology of brewer's grains and biochar, which is applied in the direction of biofuel, water pollutants, and other chemical processes, can solve the problem of low price, and achieve the effect of efficient absorption and effective resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

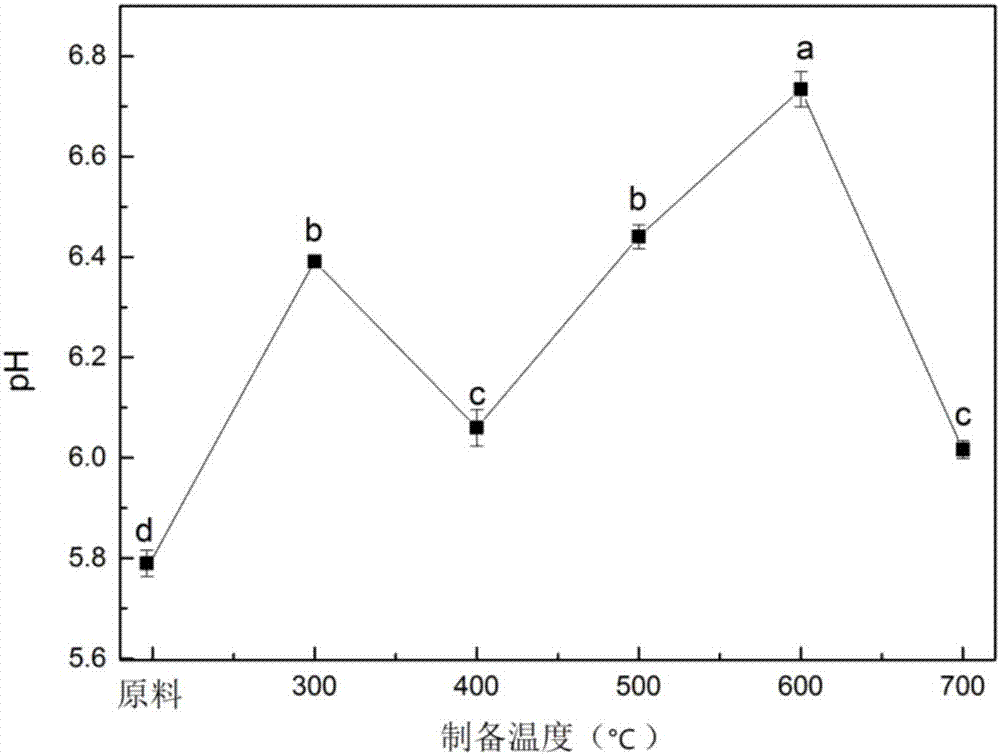

Embodiment 1

[0032] A preparation method of beer lees biochar includes the following steps:

[0033] A. Place the wet brewer's spent grains at 50℃ for 48h to dry. After drying, they are sealed in a sealed bag, and the gas inside is removed and placed in an oven for dry storage;

[0034] B. Put the crushed beer lees in a porcelain crucible, compactly cover the lid, and place it in a muffle furnace for pyrolysis and carbonization for 2 hours at a pyrolysis temperature of 700°C;

[0035] C. After cooling to room temperature, grind, pass through a 100-mesh sieve, seal and store separately, and place in an oven for dry preservation.

Embodiment 2

[0037] A preparation method of beer lees biochar includes the following steps:

[0038] A. Place the wet brewer's spent grains at 40°C for 60 hours and dry them in a sealed bag after drying, remove the gas inside, and place them in an oven for dry storage;

[0039] B. Put the crushed beer lees in a porcelain crucible, compactly cover the lid, and place it in a muffle furnace for pyrolysis and carbonization for 3 hours at a pyrolysis temperature of 300°C;

[0040] C. After cooling to room temperature, grind, pass through a 100-mesh sieve, seal and store separately, and place in an oven for dry preservation.

Embodiment 3

[0042] A preparation method of beer lees biochar includes the following steps:

[0043] A. Place the wet brewer's spent grains at 60°C for 36 hours and dry it in a sealed bag after drying, remove the gas inside, and place it in an oven for dry storage;

[0044] B. Put the crushed beer lees in a porcelain crucible, compactly cover it, and place it in a muffle furnace for pyrolysis and carbonization at a pyrolysis temperature of 750°C for 1 hour;

[0045] C. After cooling to room temperature, grind, pass through a 100-mesh sieve, seal and store separately, and place in an oven for dry preservation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com