an ag/agcl/tio 2 Composite photocatalytic material, preparation method and application thereof

A composite photocatalysis and application technology, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve outstanding problems, and achieve the effect of simple conditions, excellent photocatalytic degradation activity, and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

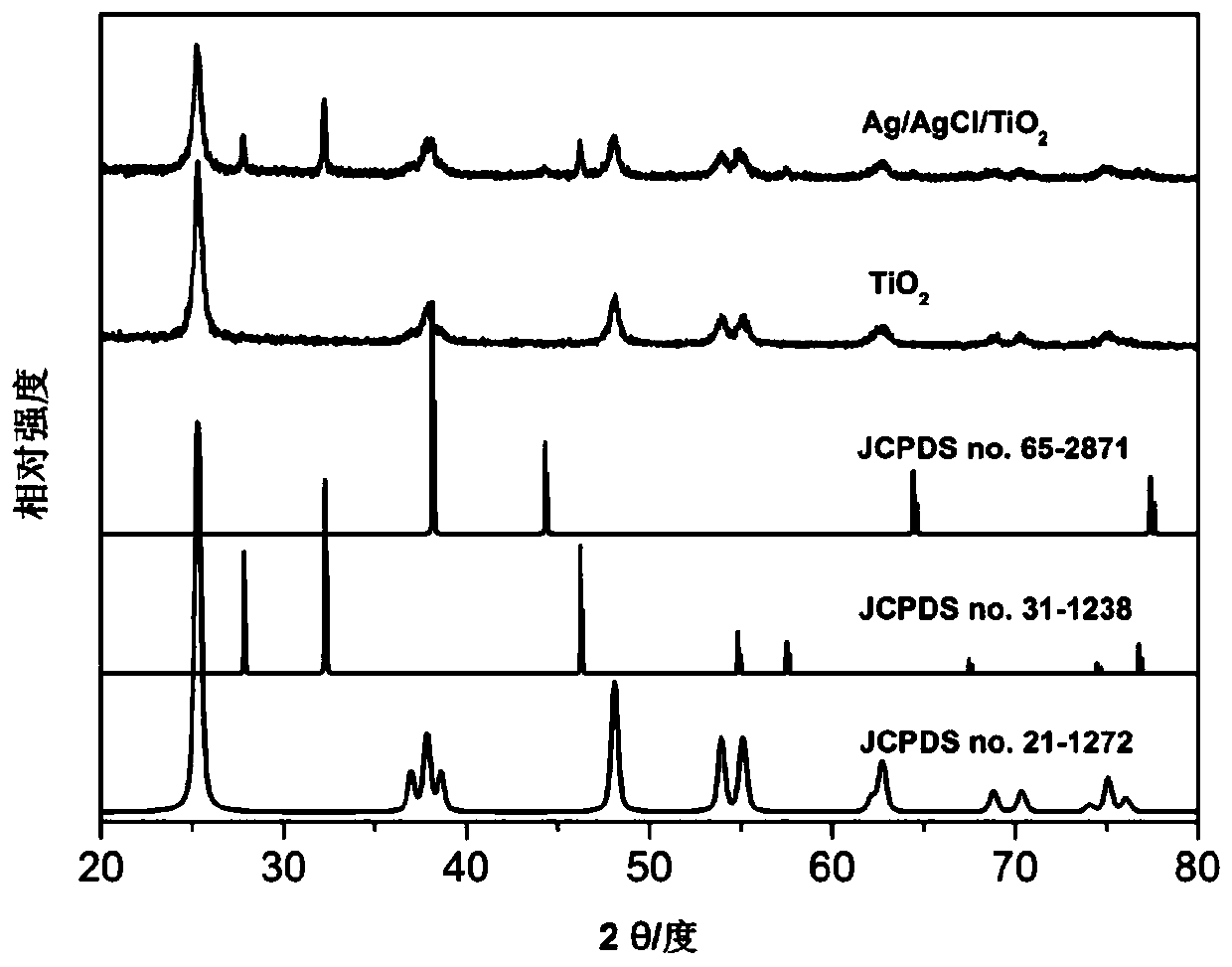

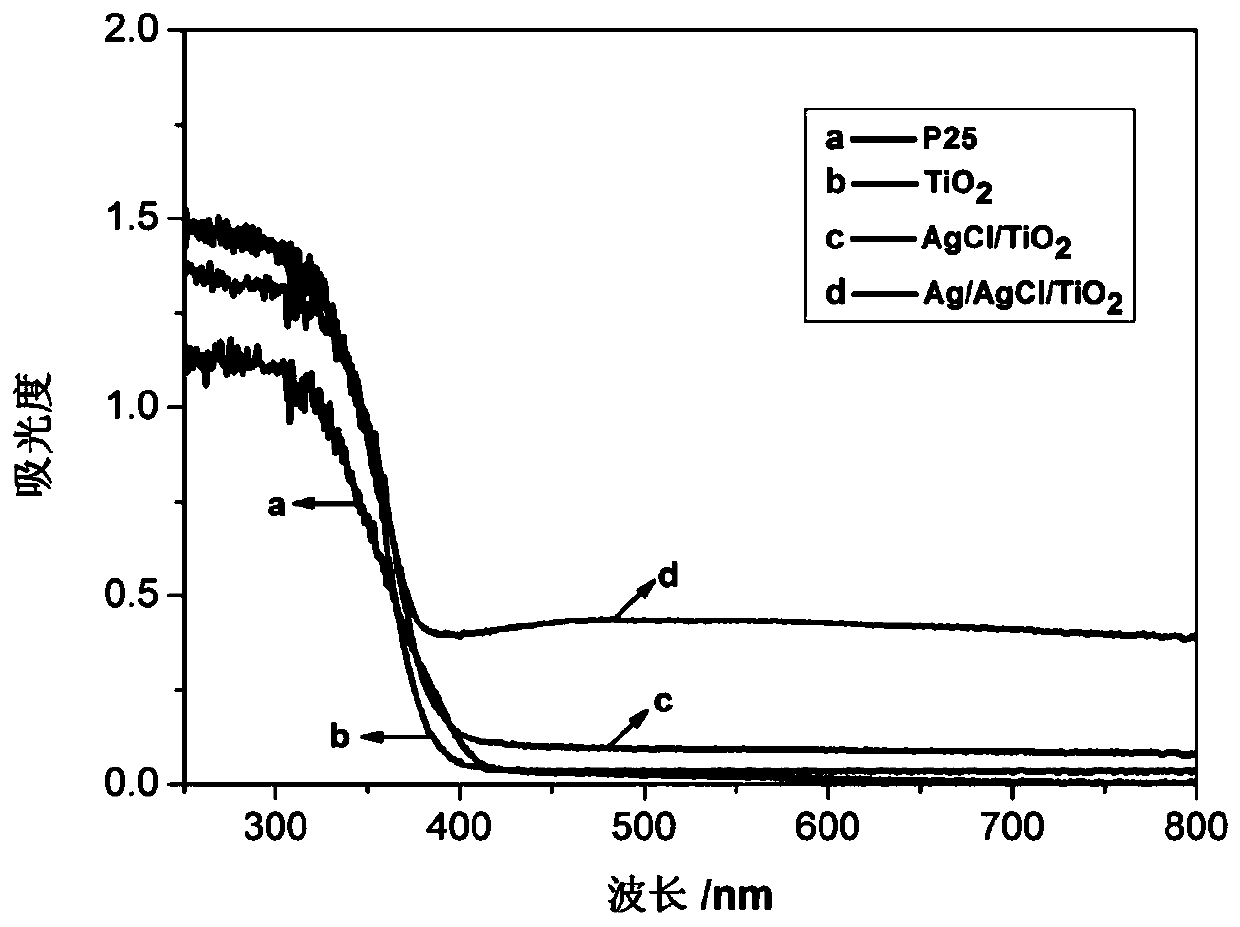

[0038] In one embodiment of the present application, a Ag / AgCl / TiO 2 The preparation method of composite photocatalytic material, the steps are as follows:

[0039] With spherical titanium dioxide as carrier, silver nitrate as silver source, 1-octyl-3-methylimidazolium chloride salt or hydrochloric acid solution as chlorine source, AgCl is loaded on the surface of spherical titanium dioxide; after photoreduction, the surface of spherical titanium dioxide Silver ions in AgCl are reduced to elemental silver to obtain Ag / AgCl / TiO 2Composite photocatalytic materials.

[0040] As a preferred solution, the method of loading AgCl on the surface of spherical titanium dioxide can adopt hydrothermal co-precipitation method and immersion co-precipitation method.

[0041] Wherein, the method for loading AgCl by the hydrothermal co-precipitation method has the following steps:

[0042] (1) Add 1-octyl-3-methylimidazolium chloride salt, titanium dioxide and PVP into deionized water, stir...

Embodiment 1

[0052] Example 1: Ag / AgCl / TiO 2 Preparation of composite photocatalytic materials

[0053] Specific steps are as follows:

[0054] (1) Preparation of TiO by solvothermal method 2 Precursor:

[0055] First, measure 90ml of glacial acetic acid with a measuring cylinder and pour it into a 150ml beaker, then add 3.0ml of tetrabutyl titanate dropwise into the glacial acetic acid with a pipette gun, and keep stirring for 60 minutes. After the stirring was completed, the obtained white emulsion was transferred to a 120ml polytetrafluoroethylene-lined autoclave, and then the autoclave was placed in a temperature-controlled oven at 150°C for 12 hours of reaction. After the reaction, take out the reaction kettle, cool it down to room temperature naturally, and finally wash the precipitate with absolute ethanol 2-3 times during the suction filtration process, and dry it at 60-70°C to obtain TiO 2 Precursor powder.

[0056] (2) Preparation of anatase phase TiO 2 :

[0057] A certai...

Embodiment 2

[0063] Example 2: Ag / AgCl / TiO 2 Preparation of composite photocatalytic materials

[0064] Specific steps are as follows:

[0065] (1) Preparation of TiO by solvothermal method 2 Precursor:

[0066] First, measure 90ml of glacial acetic acid with a measuring cylinder and pour it into a 150ml beaker, then add 3.0ml of tetrabutyl titanate dropwise into the glacial acetic acid with a pipette gun, and keep stirring for 60 minutes. After the stirring was completed, the obtained white emulsion was transferred to a 120 ml polytetrafluoroethylene-lined autoclave, and then the autoclave was placed in a temperature-controlled oven at 150° C. for 12 hours. After the reaction, take out the reaction kettle, cool it down to room temperature naturally, and finally wash the precipitate with absolute ethanol 2-3 times during the suction filtration process, and dry it at 60-70°C to obtain TiO 2 Precursor powder.

[0067] (2) Preparation of anatase phase TiO 2 :

[0068] A certain mass of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com