A kind of ceo2/bi2wo6/mgal-ldh composite photocatalyst and its preparation method and application

A technology of catalyst and composite light, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., to achieve good photocatalytic degradation activity, less pollution, and rich preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

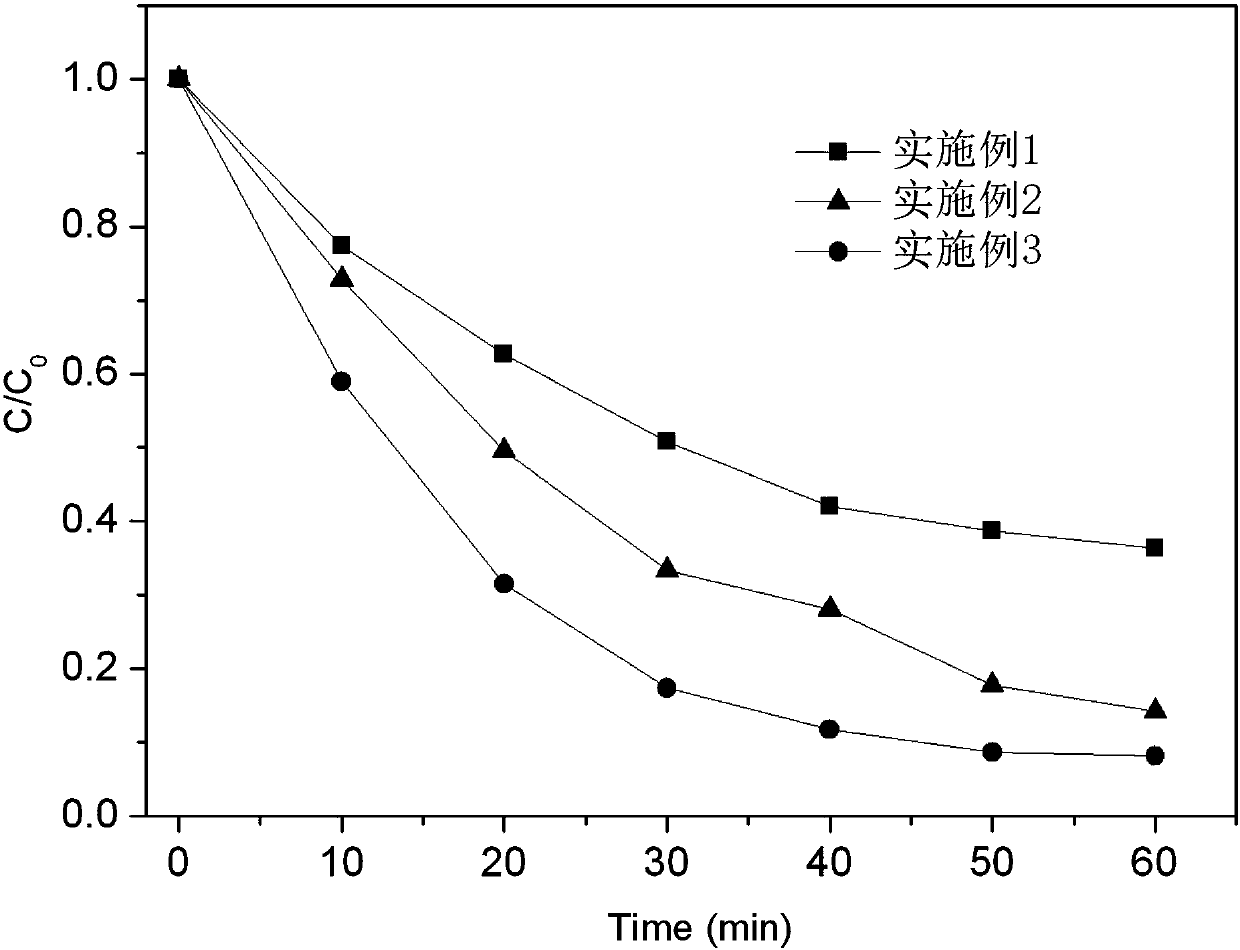

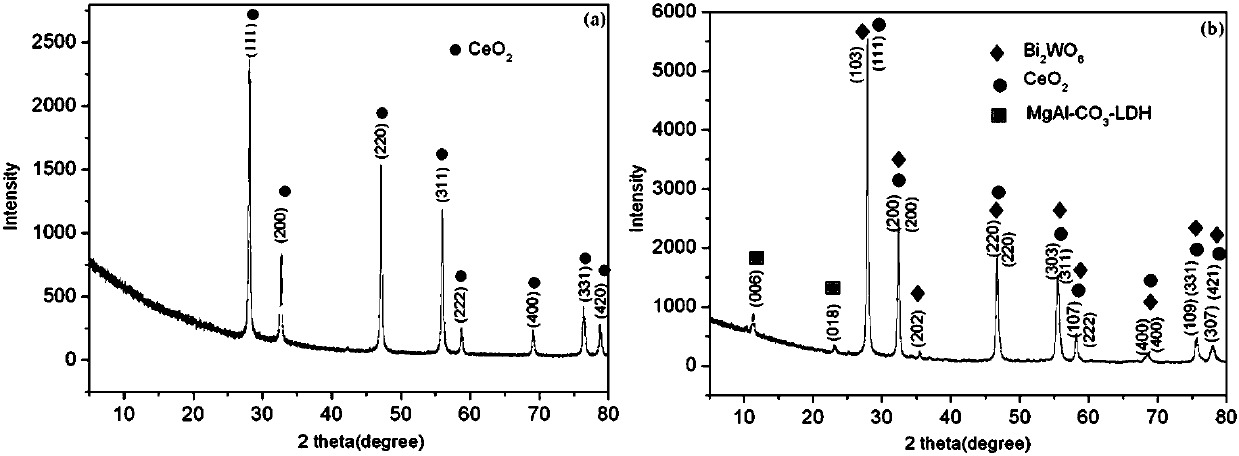

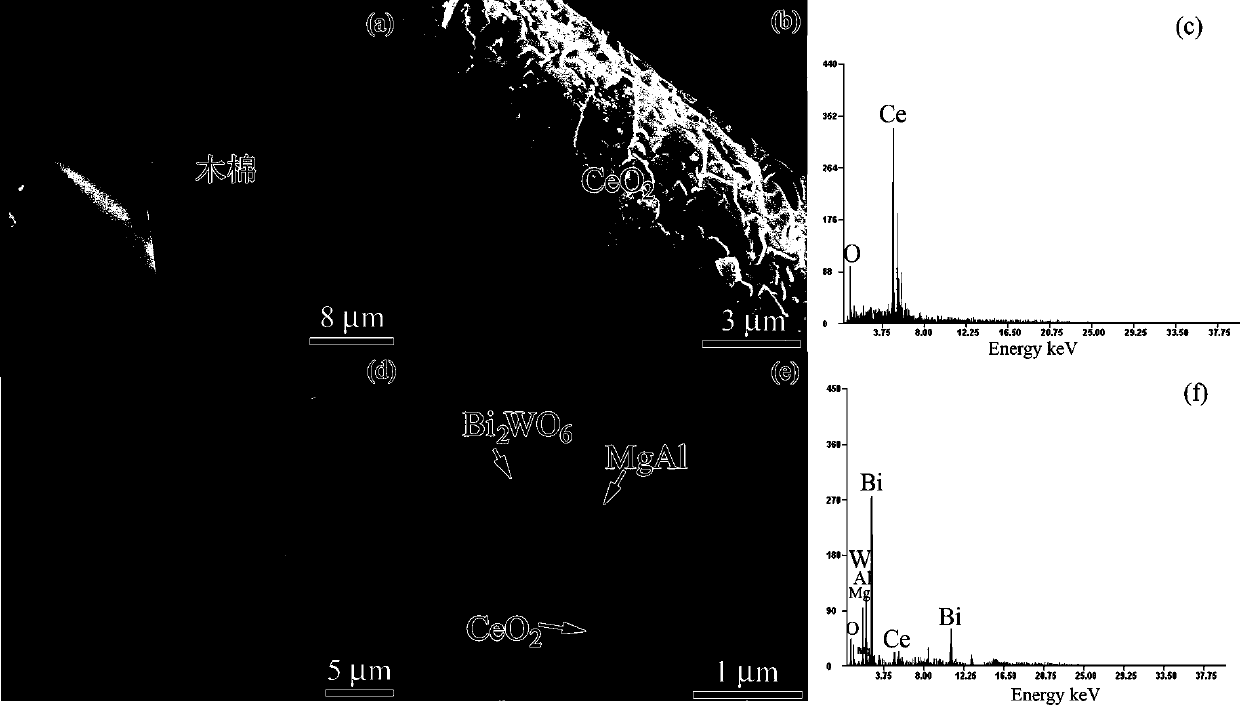

Embodiment 1

[0025] Soak 4 g of kapok in 80 mL of NaOH (20wt%), let it stand at room temperature for 24 h, filter it dry, put it in a drying oven at 80°C for 10 h, and obtain pretreated kapok; take 4 g of pretreated kapok, impregnate Put it into 200 mL ethanol solution of cerium nitrate with a concentration of 0.5 mol / L, let it stand for 8 h; take out the impregnated kapok, dry it, and calcinate it in a muffle furnace at 500 °C for 0.5 h to obtain CeO 2 . Take 0.5 mmol, 1.5 mmol, 1.5 mmol of aluminum nitrate, magnesium sulfate and urea, mix them and dissolve them in 60 mL of distilled water, add 2 g of CeO 2 , after magnetic stirring for 20 min, put it into a 100 mL reaction kettle, keep it in an incubator at 160 °C for 16 h, after cooling, filter, wash and dry to obtain CeO 2 / MgAl-LDH.

[0026] Dissolve 5 mmol of bismuth nitrate in 2.5 mL of 20 wt% nitric acid solution to obtain solution A; dissolve 2.5 mmol of sodium tungstate in 20 mL of ethylene glycol to obtain solution B; pour sol...

Embodiment 2

[0028] Soak 4 g of kapok in 80 mL of NaOH (20wt%), let it stand at room temperature for 24 h, filter it dry, put it in a drying oven at 80°C for 10 h, and obtain pretreated kapok; take 4 g of pretreated kapok, impregnate Put it into 200 mL ethanol solution of cerium nitrate with a concentration of 0.5 mol / L, and let it stand for 8 h; take out the impregnated kapok, dry it, and calcinate it in a muffle furnace at 500 °C for 0.5 h to obtain CeO 2 . Take 0.5 mmol, 1.5 mmol, 1.5 mmol of aluminum nitrate, magnesium sulfate and urea, mix them and dissolve them in 60 mL of distilled water, add 2 g of CeO 2 , after magnetic stirring for 20 min, put it into a 100 mL reaction kettle, keep it in an incubator at 160 °C for 16 h, after cooling, filter, wash and dry to obtain CeO 2 / MgAl-LDH.

[0029] Dissolve 5 mmol of bismuth nitrate in 2.5 mL of 20 wt% nitric acid solution to obtain solution A; dissolve 2.5 mmol of sodium tungstate in 20 mL of ethylene glycol to obtain solution B; pour...

Embodiment 3

[0031] Soak 4 g of kapok in 80 mL of NaOH (20wt%), let it stand at room temperature for 24 h, filter it dry, put it in a drying oven at 80°C for 10 h, and obtain pretreated kapok; take 4 g of pretreated kapok, impregnate Put it into 200 mL ethanol solution of cerium nitrate with a concentration of 0.5 mol / L, and let it stand for 8 h; take out the impregnated kapok, dry it, and calcinate it in a muffle furnace at 500 °C for 0.5 h to obtain CeO 2 . Take 0.5 mmol, 1.5 mmol, 1.5 mmol of aluminum nitrate, magnesium sulfate and urea, mix them and dissolve them in 60 mL of distilled water, add 2 g of CeO 2 , after magnetic stirring for 20 min, put it into a 100 mL reaction kettle, keep it in an incubator at 160 °C for 16 h, after cooling, filter, wash and dry to obtain CeO 2 / MgAl-LDH.

[0032] Dissolve 5 mmol of bismuth nitrate in 2.5 mL of 20 wt% nitric acid solution to obtain solution A; dissolve 2.5 mmol of sodium tungstate in 20 mL of ethylene glycol to obtain solution B; pour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com