Catalyst system for preparing polyether material for aviation

A catalyst and reaction system technology, applied in the application field of polymerization, can solve the problems of not meeting the application requirements in the aviation field, limiting the application range, transition metals and cyanide residues, etc., achieving controllable molecular weight and its distribution, and a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A composition for the controllable polymerization of epoxy monomer living anion, its molar composition is:

[0032] 1 part of tetrabutylammonium chloride, 1 part of triethylboron.

Embodiment 2

[0034] A composition for the controllable polymerization of epoxy monomer living anion, its molar composition is:

[0035] 1 part of tetrabutyl phosphorus chloride, 2 parts of triethyl boron.

Embodiment 3

[0037] A composition for the controllable polymerization reaction of epoxy monomer living anion, which consists of:

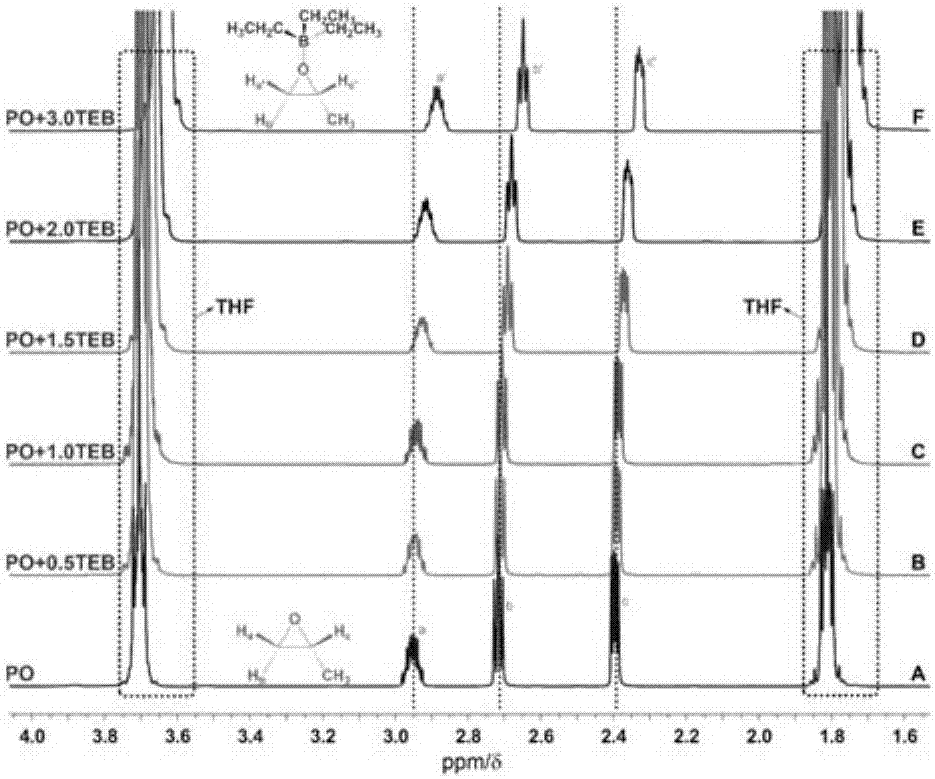

[0038] Tetrabutylammonium chloride 0.0573mmol, triethylboron 0.0859mmol, tetrahydrofuran 2ml.

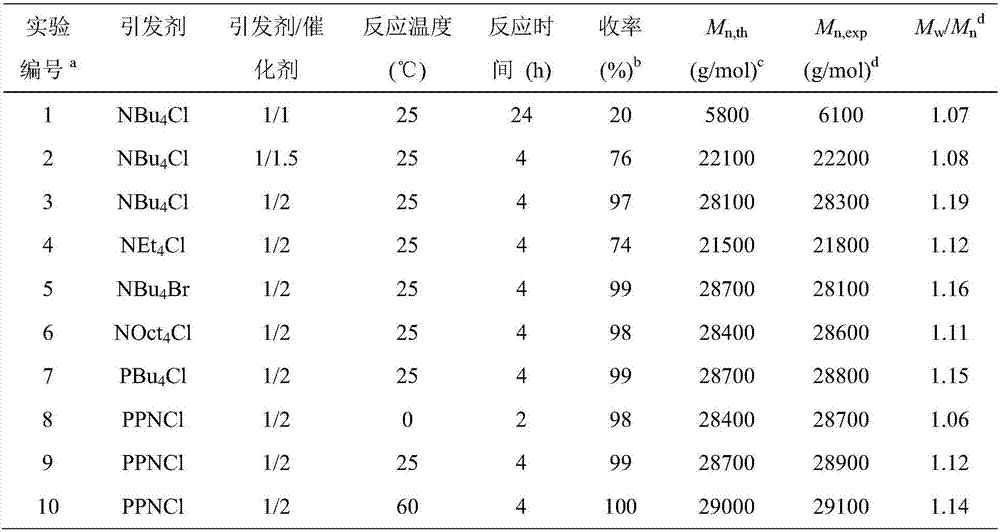

[0039] Embodiment 4 Halogenated quaternary ammonium salt or halogenated quaternary phosphonium salt initiates preparation of propylene oxide homopolymer

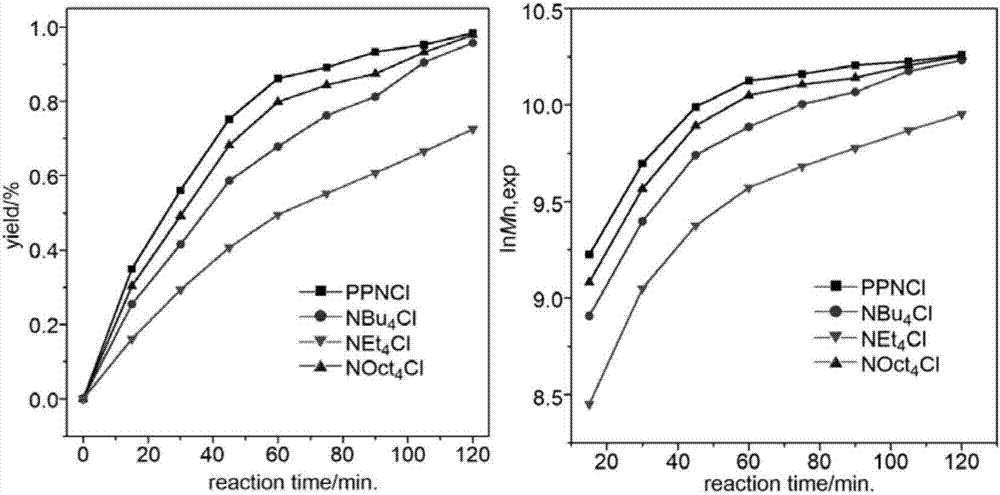

[0040]Taking experiment 7 in table 1 as an example, the relevant reaction material consumption and experimental operation are as follows: in an inert atmosphere environment, accurately take by weighing tetrabutylphosphorus chloride initiator 0.0169g in proportion, place it in a vacuum line to remove Polymer tubes for water treatment. After adding 2ml of tetrahydrofuran, add 114μl of 0.8mol / L triethylboron catalyst tetrahydrofuran solution, stir and mix well, then quickly add 2ml (29mmol) of propylene oxide monomer (the molar ratio of monomer to initiator is 500 / 1) , Seal the system and place it in a constant temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com