High elastic environment-friendly polyvinyl chloride material composition and its preparation method and application

A material composition, polyvinyl chloride technology, applied in the field of new materials, can solve the problems of large environmental impact, poor thermal stability, high price, etc., and achieve the effect of good gloss, improved stability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

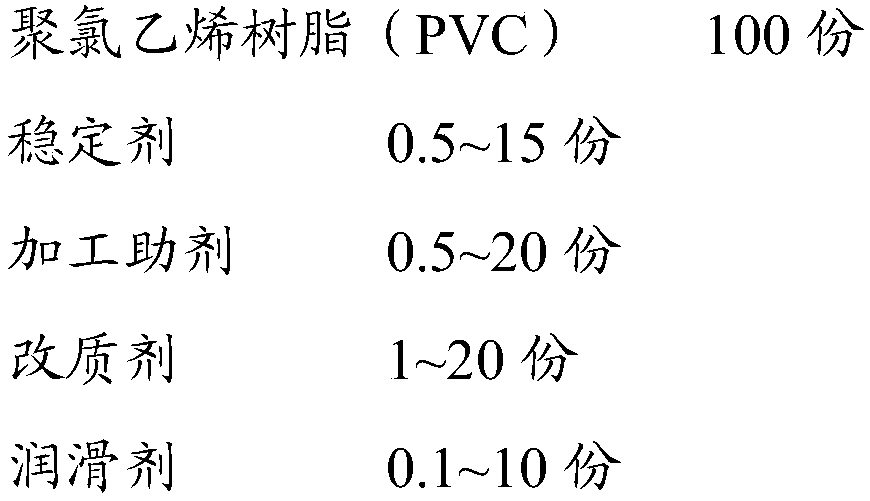

[0028] The present embodiment is a highly elastic environment-friendly polyvinyl chloride material composition, which includes the following raw material components:

[0029]

[0030]

[0031] The preparation method of the above-mentioned highly elastic environment-friendly polyvinyl chloride material composition comprises the following steps:

[0032] Step 1: Weighing various raw materials according to the mass / number ratio;

[0033] Step 2: Add the PVC, stabilizer, processing aid, modifier, lubricant, filler and colorant into a hot mixer, and mix thoroughly for 5-10 minutes;

[0034] The third step: the uniformly mixed material in the second step is extruded through a star-shaped screw extruder at a temperature of 150-180°C, sheared and pre-plasticized, and further plasticized at a temperature of 130-160°C in an open mill, and then pressed by a calender The sheet is formed, drawn out by a stretching machine, cooled and shaped, and rolled to obtain a PVC hard material,...

Embodiment 2

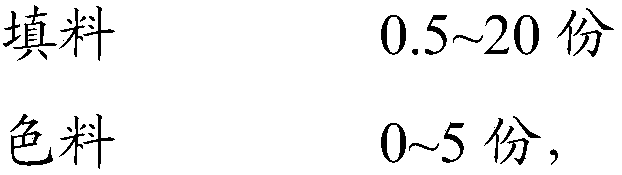

[0036] The present embodiment is a highly elastic environment-friendly polyvinyl chloride material composition, which includes the following raw material components:

[0037] raw material

[0038] The preparation method of the above-mentioned highly elastic environment-friendly polyvinyl chloride material composition is the same as that in Example 1.

Embodiment 3

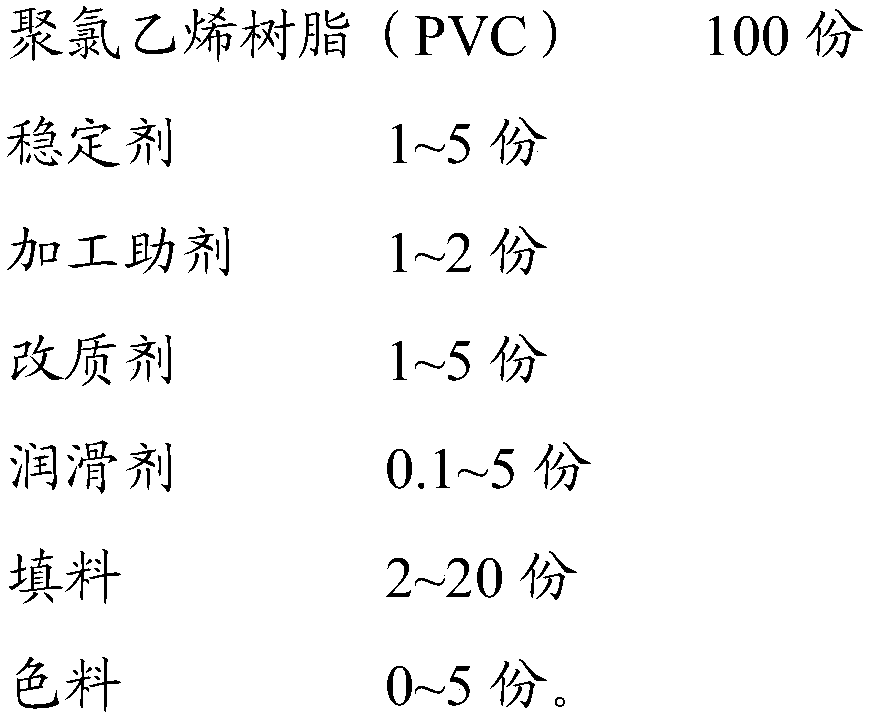

[0040] The present embodiment is a highly elastic environment-friendly polyvinyl chloride material composition, which includes the following raw material components:

[0041] raw material

[0042] The preparation method of the above-mentioned highly elastic environment-friendly polyvinyl chloride material composition is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com