Liquid shell powder coating as well as preparation method thereof

A technology of shell powder and paint, applied in the direction of coating, etc., can solve the problems of high technical requirements and complicated construction, and achieve the effect of rich colors, convenient construction, and low construction technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

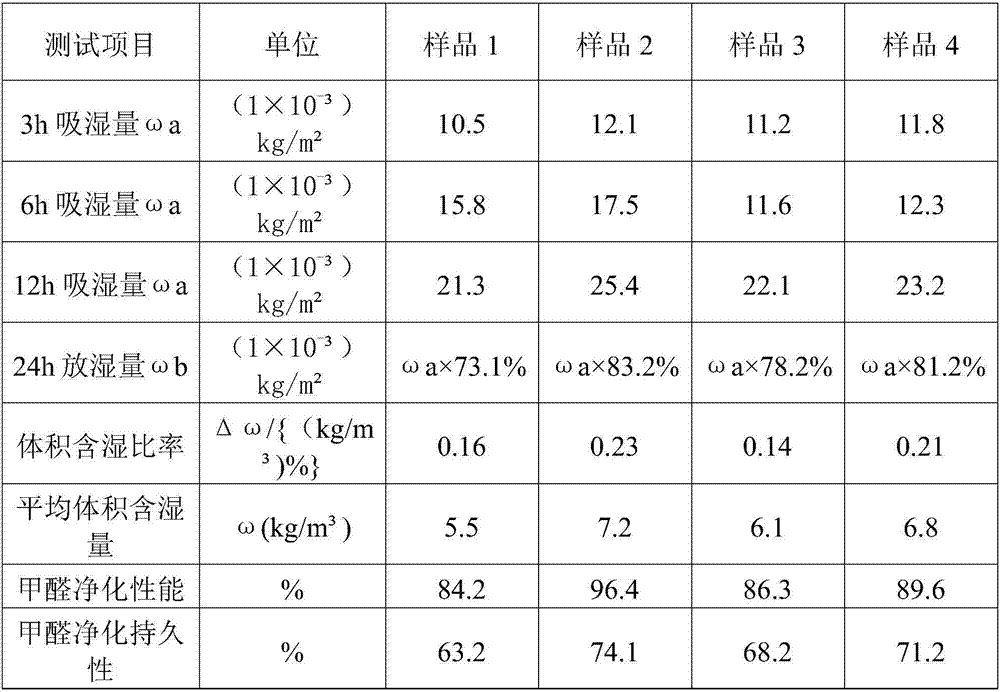

Examples

Embodiment 1

[0022] Add 31 parts of distilled water into the dispersion tank, start the stirring equipment, set the speed at 300 rpm, add 6 parts of hydroxyethyl cellulose (3500), 0.3 parts of wetting agent (RT-1096), dispersant (RT-8040) 0.3 parts, bactericide (LXE) 0.2 parts, propylene glycol 2 parts, defoamer A (643) 0.8 parts, after adding, continue to stir and disperse for 40 minutes to prepare a slurry. Then adjust the rotating speed of the stirring equipment to 1000 rpm, and add 3 parts of anatase titanium dioxide, 11 parts of 1250 mesh shell powder, 5 parts of 800 mesh heavy calcium, and 6 parts of 800 mesh kaolin respectively in the slurry. Continue to stir and disperse for 40 minutes to prepare the base material. Then reduce the speed of the stirring equipment to 300 rpm, and add 15 parts of emulsion (ECO-338), 3 parts of film-forming aid (OE-300) and 0.1 part of defoamer (NXZ) to the base material in sequence. Continue to stir and disperse for 30 minutes after the addition is c...

Embodiment 2

[0024] Add 24.8 parts of distilled water into the dispersion tank, start the stirring equipment, set the speed at 350 rpm, add 4.5 parts of hydroxyethyl cellulose (3500), 0.8 parts of wetting agent (RT-1096), dispersant (RT-8040) 0.5 parts, fungicide (LXE) 0.4 parts, propylene glycol 6 parts, defoamer A (643) 0.2 parts, after adding, continue to stir and disperse for 30 minutes to prepare a slurry. Then adjust the rotating speed of the stirring equipment to 800 rpm, and add 4.5 parts of anatase titanium dioxide, 12 parts of 1250 mesh shell powder, 8 parts of 800 mesh heavy calcium, and 10 parts of 800 mesh kaolin to the slurry in sequence. Continue to stir and disperse for 50 minutes to prepare the base material. Then reduce the speed of the stirring equipment to 400 rpm, and add 10 parts of emulsion (ECO-338), 5 parts of film-forming aid (OE-300) and 0.2 parts of defoamer (NXZ) to the base material in sequence. Continue to stir and disperse for 30 minutes after the addition ...

Embodiment 3

[0026] Add 27.5 parts of distilled water into the dispersion tank, start the stirring equipment, set the speed at 350 rpm, add 3.5 parts of hydroxyethyl cellulose (3500), 1 part of wetting agent (RT-1096), dispersant (RT-8040) 0.8 parts, fungicide (LXE) 0.6 parts, propylene glycol 4 parts, defoamer A (643) 0.3 parts, after adding, continue to stir and disperse for 30 minutes to prepare a slurry. Then adjust the rotating speed of the stirring equipment to 800 rpm, and add 6.5 parts of anatase titanium dioxide, 10 parts of 1250 mesh shell powder, 10 parts of 800 mesh heavy calcium, and 8 parts of 800 mesh kaolin respectively in the slurry. Continue to stir and disperse for 50 minutes to prepare the base material. Then reduce the speed of the stirring equipment to 400 rpm, and add 5 parts of emulsion (ECO-338), 8 parts of film-forming aid (OE-300) and 0.3 parts of defoamer (NXZ) to the base material in sequence. Continue to stir and disperse for 30 minutes after the addition is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com