Ring Fiber with Asymmetric Grating and Its Application in Orbital Angular Momentum Generation

An orbital angular momentum, asymmetric technology, applied in the field of optics, can solve the problems of poor long-term stability, large structure size, narrow orbital angular momentum wavelength, etc., to achieve effective separation and stable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A hollow-core annular fiber with an asymmetric long-period fiber grating is used to realize the conversion between angularly non-same-order modes in the ring, including the following steps:

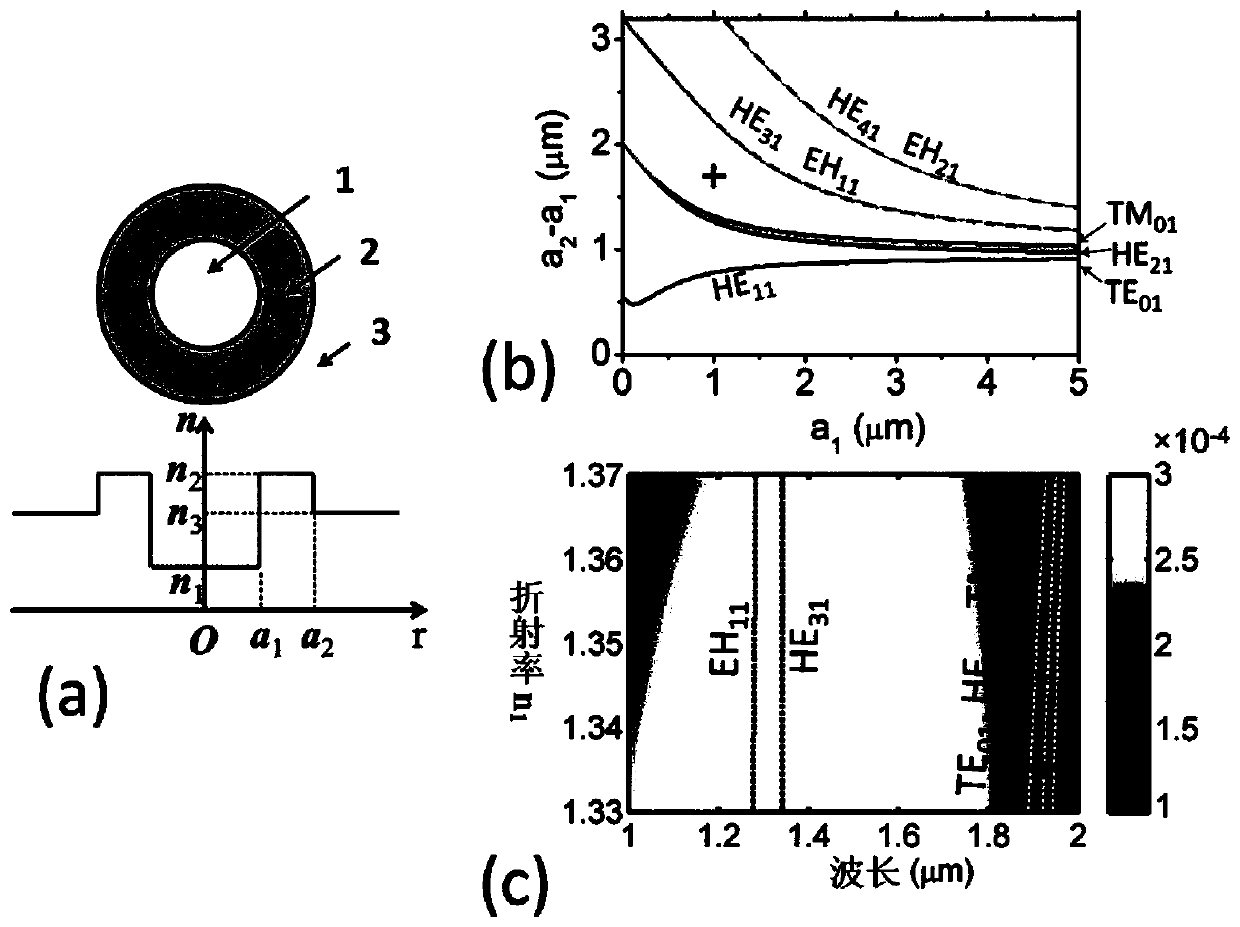

[0037] Step 1: Fabricate a hollow-core ring-shaped optical fiber by chemical vapor deposition and optical fiber drawing equipment. Hollow-core ring fibers have a high-refractive-index ring to transmit light within the high-refractive-index ring. The end face of the hollow core ring fiber is as figure 1 As shown in (a), the refractive index n of liquid filled in the hollow core 1 =1.33-1.37, high refractive index ring refractive index n 2 =1.47, cladding refractive index n 3 = 1.44. The beam modes supported in the ring core can be adjusted by adjusting the inner diameter of the ring core a 1 and outer diameter a 2 decide, such as figure 1 (b) shown. The ring core fiber size is determined as a 1 = 1 μm and a 2 =2.7μm, this parameter makes the high-refractive index ring only...

Embodiment 2

[0041] A hollow-core annular optical fiber with an asymmetric long-period grating, used for wavelength tunable orbital angular momentum mode generation, comprising the following steps:

[0042] Step 1: Fabricate a hollow-core ring-shaped optical fiber by chemical vapor deposition and optical fiber drawing equipment. Hollow-core ring fibers have a high-refractive-index ring to transmit light within the high-refractive-index ring. The end face of the hollow core ring fiber is as figure 1 As shown in (a), the refractive index n of liquid filled in the hollow core 1 =1.33-1.37, high refractive index ring refractive index n 2 =1.47, cladding refractive index n 3 = 1.44. The beam modes supported in the ring core can be adjusted by adjusting the inner diameter of the ring core a 1 and outer diameter a 2 decide, such as figure 1 (b) shown. The ring core fiber size is determined as a 1 = 1 μm and a 2 =2.7μm, this parameter makes the high-refractive index ring only support the...

Embodiment 3

[0049] A hollow-core annular optical fiber with an asymmetric long-period grating, used for wavelength tunable orbital angular momentum mode generation, comprising the following steps:

[0050] Step 1: with embodiment 2;

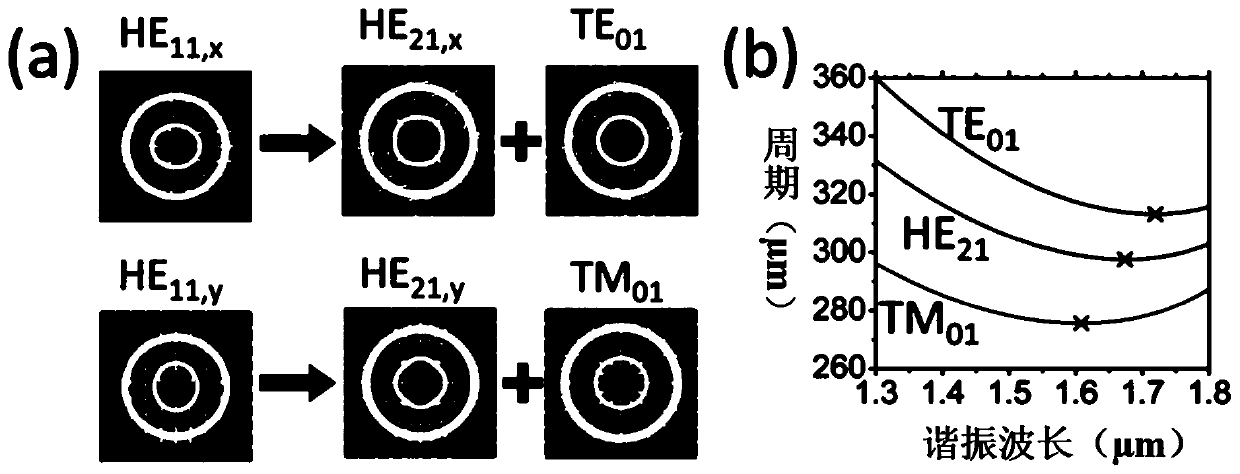

[0051] Step 2: Through unilateral UV exposure of the hollow core ring fiber filled with opaque liquid, the periodic refractive index modulation of the upper half ring is realized, and a hollow core ring fiber with an asymmetric grating is made. Its structure is as follows figure 2 shown. The upper half of the high-index ring is subjected to a periodic index modulation with a refractive index n 2 +Δn, the refractive index change value is Δn=2.6×10 -4 ; The refractive index of the lower half ring remains unchanged as n 2 , the grating period is 287 μm, and the number of grating periods is 40.

[0052] Step 3, step 4, step 5: same as embodiment 2;

[0053] Step 6: Adjust environmental parameters such as magnetic field, electric field, temperature, etc. to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com