A multi-dimensional knowledge cloud coordination service method for complex curved surface processing

A collaborative service and complex surface technology, applied in the direction of comprehensive factory control, instrumentation, computer control, etc., can solve the problems of knowledge resource packaging, on-demand configuration of knowledge resources, accurate push and deterioration, etc., to save processing time and information costs, reduce Waste of resources and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

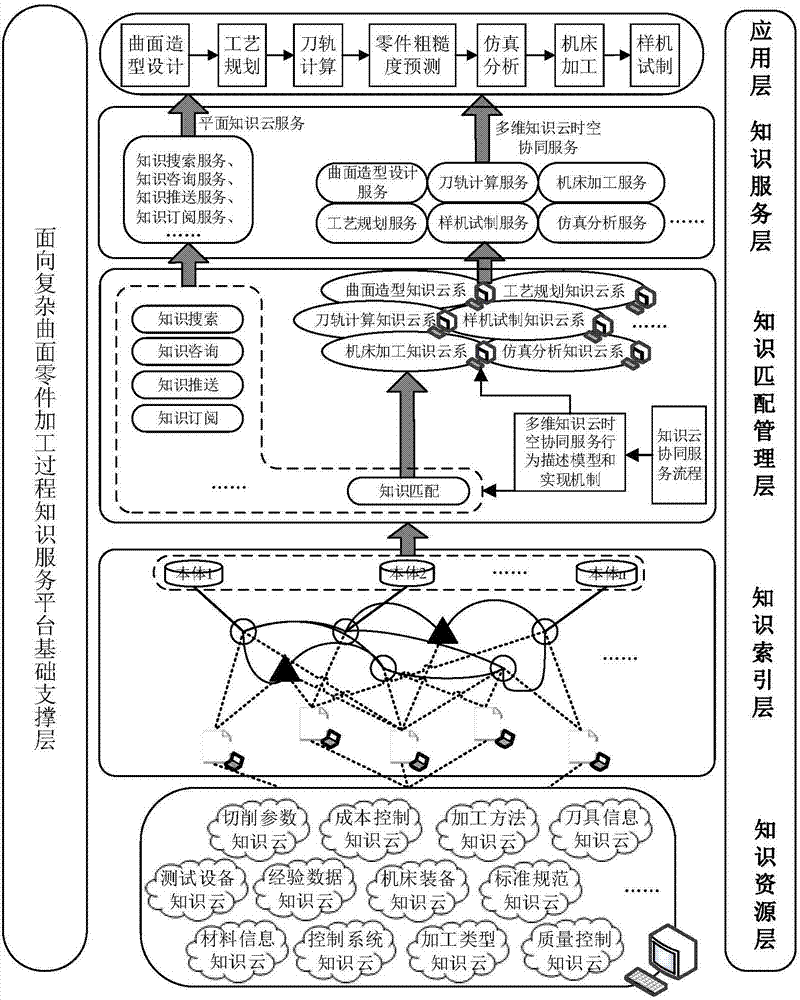

[0035] Embodiment 1: as Figure 1-7 As shown, a complex surface processing multi-dimensional knowledge cloud collaborative service method, the execution process of the knowledge collaborative service method is based on the six layers of the service system, the basic support layer is connected with the other five layers, and serves as the basis for the other five layers in the knowledge service process Each layer provides network services, various application software and hardware resources; the service system architecture includes: basic support layer, knowledge resource layer, knowledge index layer, knowledge matching management layer, knowledge service layer, and application layer;

[0036] According to the order of construction, this method includes the following steps:

[0037] Step 1: Analyze the knowledge cloud composition of complex curved surface parts processing process and the behavior attributes and characteristics of related processing knowledge cloud service, cons...

Embodiment 2

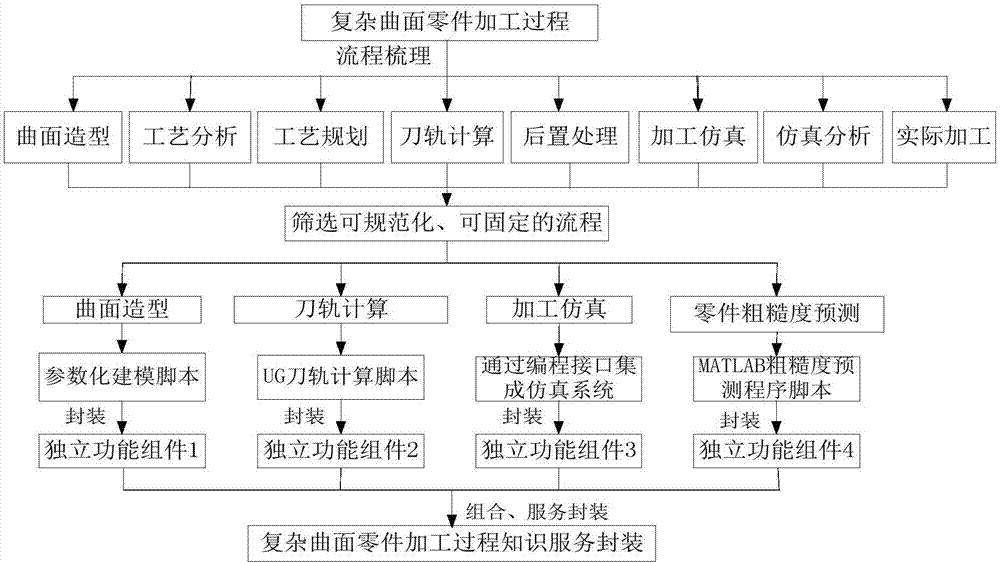

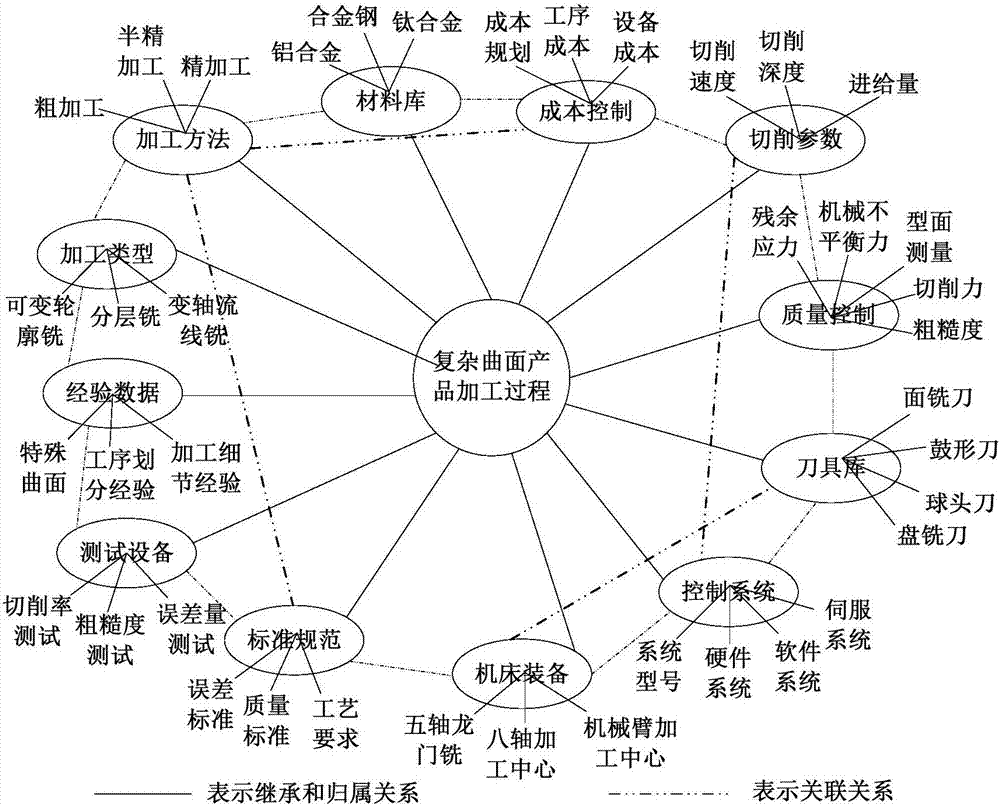

[0052] Embodiment 2: as figure 2 As shown, the processing process from the blank of the part to the finished part is composed of multiple knowledge service behaviors, and each service behavior corresponds to the knowledge resources that need to be pushed for the processing of a complex surface part, including processing equipment, control mode, tool, material , processing type, processing method, cutting parameters, standard specifications, experience data and other knowledge resources in multiple professional fields, forming a complex many-to-many mapping relationship from feature profiles to knowledge resources, knowledge cloud drops, knowledge clouds, knowledge cloud systems form a complex coupling relationship.

[0053] According to the order of construction, this method includes the following steps:

[0054] Step 1: If image 3 As shown in Fig. 1, the knowledge cloud composition of complex curved surface parts processing process and the behavior attributes and characte...

Embodiment 3

[0072] Embodiment 3: as Figure 7 As shown, according to the construction steps of this method, taking the knowledge service process of turbine blade machining as an example, the execution flow of knowledge service behavior in the knowledge cloud service platform of complex curved surface parts machining process is explained: firstly, the machining task is decomposed and released, After obtaining the task, the user reads the task information, including the type of processing task, basic information, task requirements, etc., and converts the task of "turbine blade tool path calculation" into "processing area division", "processing equipment selection", " According to the knowledge requirements of the task sequence of "tool path planning", "tool attitude control" and "cutting parameter determination", and the domain ontology of the common knowledge cloud and its relationship based on the established complex surface tool path calculation, construct the knowledge cloud droplet in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com