Superjunction reverse conducting-insulated gate bipolar transistor (IGBT) with collector groove

A collector and reverse conduction technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as uneven current distribution and poor diode characteristics, achieve fast turn-off speed, eliminate snapback effect, and eliminate voltage foldback Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

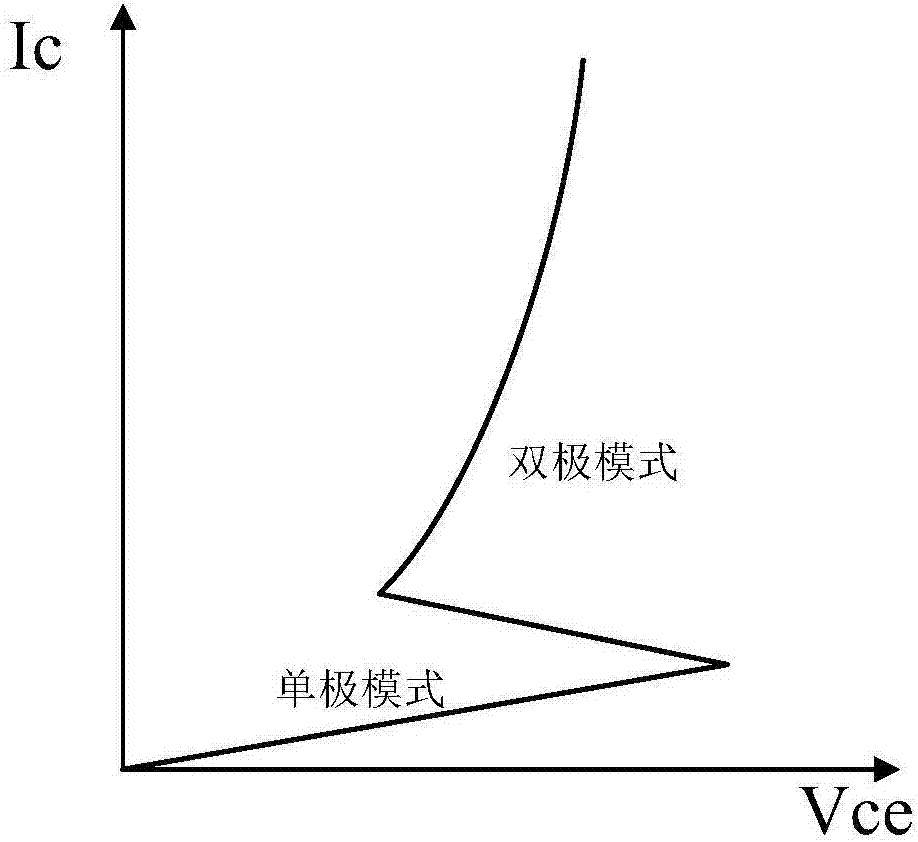

Problems solved by technology

Method used

Image

Examples

Embodiment 1

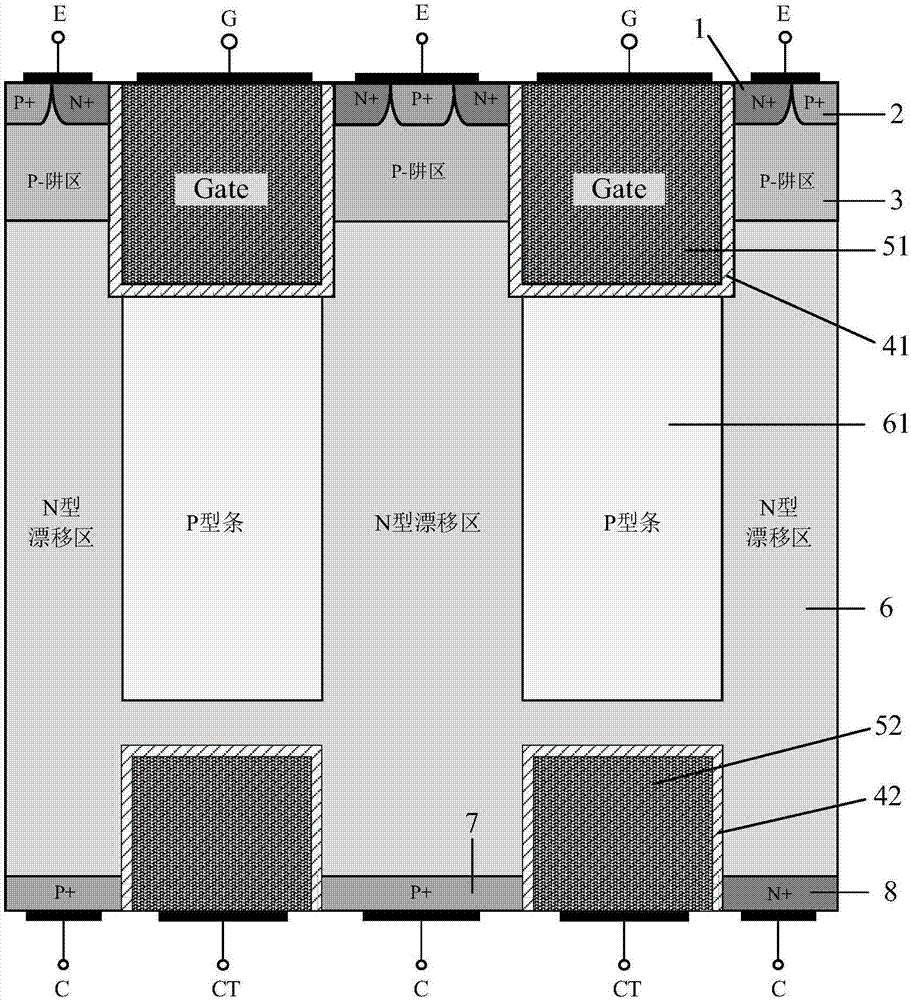

[0025] Such as figure 2 As shown, the superjunction inverse conduction IGBT with collector grooves in this example includes a MOS cell structure, an N-type drift region 6 and a collector structure from top to bottom; the MOS cell structure includes a groove gate and a P-type Well region 3; the slot gate includes a first insulating layer 41 and a first conductive material 51 located in the first insulating layer 41, and the leading end of the first conductive material 51 is a gate electrode G; the slot gate passes through the The P-type well region 3 goes deep into the N-type drift region 6; the P-type well region 3 is located on both sides of the groove gate, and the upper surface of the P-type well region 3 has an N+ emitter region 1 and a P+ body contact region 2 , and the N+ emitter region 1 is in contact with the insulating layer 41, the P+ body contact region 2 is located on both sides of the N+ emitter region 1, and the common terminal of the N+ emitter region 1 and the...

Embodiment 2

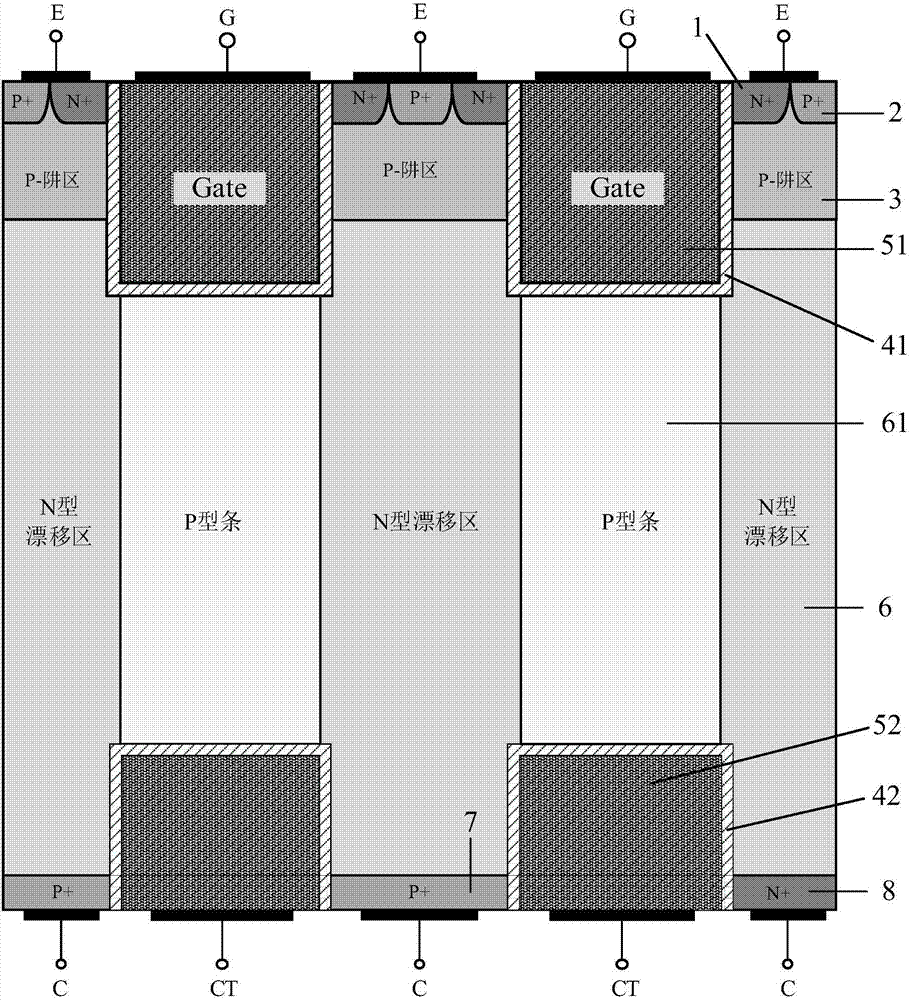

[0029] Such as image 3 As shown, the difference between this example and Example 1 is that in this example, the P-type strip 61 in the N-type drift region 6 is connected to the second insulating layer 42 of the collector groove. Compared with Example 1, in this example, the P-type strip 62 blocks the surface MOS electron current at other positions from flowing to the N+ collector region 8, and the new device is directly equivalent to a parallel connection of an IGBT and a MOS tube, thus suppressing the voltage foldback effect The effect is better.

Embodiment 3

[0031] Such as Figure 4 As shown, the difference between this example and Example 1 is that there is a voltage difference V between the second collector CT and the collector C in this example G2 . When the device is conducting forward, the voltage on the second collector CT is lower than the voltage on the collector C (that is, V G2 G2 >0), the sidewall of the second insulating layer 42 forms a high-concentration electron accumulation layer, and the electron accumulation layer and the collector groove serve as an equivalent field stop layer to ensure that the device can withstand high withstand voltage; meanwhile, the electron accumulation layer will also The potential difference between the P+ collector region 7 and the N-type drift region 6 is reduced, thereby reducing the hole injection efficiency, and it is also a channel for fast extraction of electrons, which is beneficial to improve the turn-off speed of the device. Compared with Example 1, the device in this example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com