Fiber-solid hybrid amplification laser system

A solid-state hybrid, laser system technology, applied in the laser field, can solve the problem that the peak power is difficult to reach the order of 10MW

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

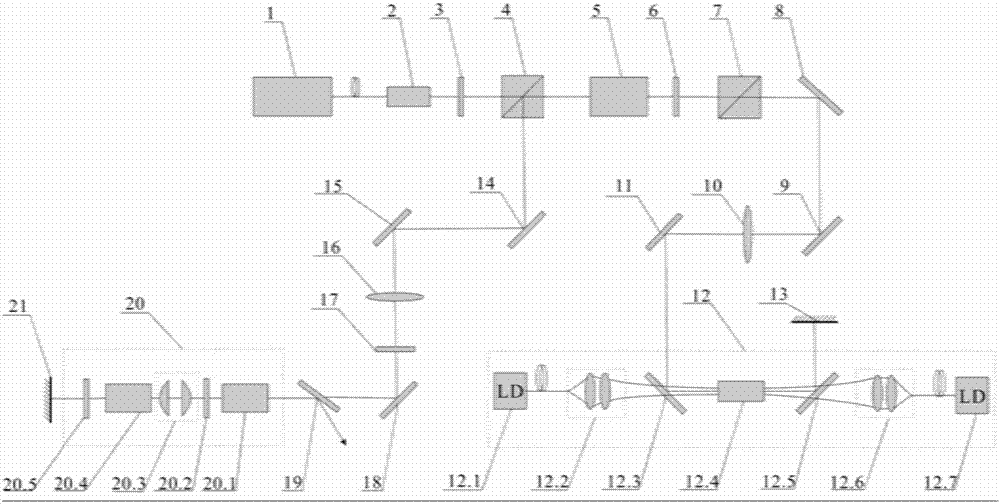

[0049] figure 1 What is shown is a schematic diagram of a fiber-solid hybrid amplified laser system provided by an embodiment of the present invention. like figure 1 As shown, the fiber-solid hybrid amplified laser system provided by the embodiment of the present invention includes: picosecond fiber laser 1, fiber isolator 2, first half-wave plate 3, second polarization beam splitter prism 4, Faraday rotator 5, second Half-wave plate 6, first polarizing beam splitter prism 7, 45° reflector 8, 45° reflector 9, first coupling lens 10, 45° reflector 11, LD double-ended pump Nd:YVO 4 Amplifier 12, first 0° mirror 13, 45° mirror 14, 45° mirror 15, second coupling lens 16, third half-wave plate 17, 45° mirror 18, film polarizer 19, LD side pump Pu Nd: YAG am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com