Regeneration method of denitration catalyst

A denitration catalyst and hot ethanol technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems that the catalyst structure enhancement cannot achieve practical effects, the solubility of silica sol is low, and the mechanical strength improvement is not fully considered. methods, etc., to achieve the effect of convenient and fast regeneration method, good activity recovery and outstanding regeneration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

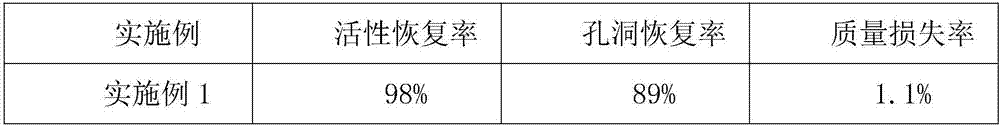

Examples

Embodiment 1

[0028] A regeneration method for a denitration catalyst, the preparation steps of which are as follows:

[0029] Step 1, put the deactivated denitrification catalyst into an aqueous ethanol solution, vibrate ultrasonically for 10 minutes, and then dry it;

[0030] Step 2, soaking the dried denitrification catalyst in acid solution and alkali solution in sequence, rinsing with deionized water, drying or drying in the air;

[0031] Step 3, put the denitrification catalyst into the electrolytic cell, add electrolyte, electrolyze for 2 hours, take it out and dry it;

[0032] Step 4, soak the dried denitration catalyst in hot ethanol for 2 hours, and then filter it with hot ethanol;

[0033] Step 5, use nitrogen or a mixture of nitrogen and air to purge for 20 minutes;

[0034] In step 6, the purged denitrification catalyst is subjected to surface electrolysis and energization reaction for 10 minutes to obtain an active regenerated denitration catalyst.

[0035] The ethanol conc...

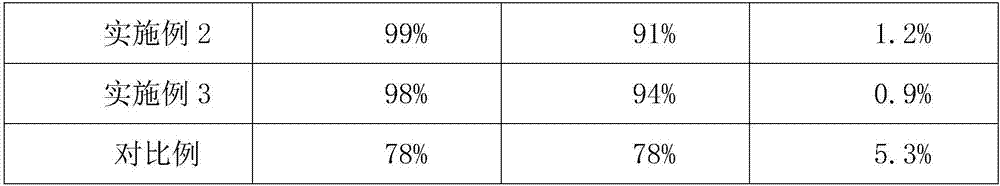

Embodiment 2

[0043] A regeneration method for a denitration catalyst, the preparation steps of which are as follows:

[0044] Step 1, put the deactivated denitration catalyst into the aqueous ethanol solution, vibrate ultrasonically for 15 minutes, and then dry it;

[0045] Step 2, soaking the dried denitrification catalyst in acid solution and alkali solution in sequence, rinsing with deionized water and drying;

[0046] Step 3, put the denitrification catalyst into the electrolytic cell, add electrolyte, electrolyze for 4 hours, take it out and dry it;

[0047] Step 4, soak the dried denitration catalyst in hot ethanol for 4 hours, and then filter it with hot ethanol;

[0048] Step 5, purging with nitrogen for 50 minutes;

[0049] In step 6, the purged denitrification catalyst is electrified by surface electrolysis for 15 minutes to obtain an active regenerated denitrification catalyst.

[0050]The ethanol concentration of the aqueous ethanol solution in the step 1 is 70%.

[0051] T...

Embodiment 3

[0058] A regeneration method for a denitration catalyst, the preparation steps of which are as follows:

[0059] Step 1, put the deactivated denitration catalyst into the aqueous ethanol solution, vibrate ultrasonically for 12 minutes, and then dry it;

[0060] Step 2, soaking the dried denitrification catalyst in acid solution and alkali solution in sequence, rinsing with deionized water and drying;

[0061] Step 3, put the denitrification catalyst into the electrolytic cell, add electrolyte, electrolyze for 3 hours, take it out and dry it;

[0062] Step 4, soaking the dried denitration catalyst in hot ethanol for 3 hours, and then filtering with hot ethanol;

[0063] Step 5, using a mixed gas of nitrogen and air to purge for 30 minutes;

[0064] In step 6, the purged denitrification catalyst is electrified by surface electrolysis for 12 minutes to obtain an active regenerated denitration catalyst.

[0065] The ethanol concentration of the aqueous ethanol solution in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com