Core-shell structure loaded tungsten composite catalyst, preparation method and application thereof

A composite catalyst and shell structure technology, applied in catalyst activation/preparation, chemical instruments and methods, chemical elements of heterogeneous catalysts, etc., can solve the problems of long synthesis steps, large amount of three wastes, complicated operation, etc., and achieve low production cost. , The effect of less strong alkali and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

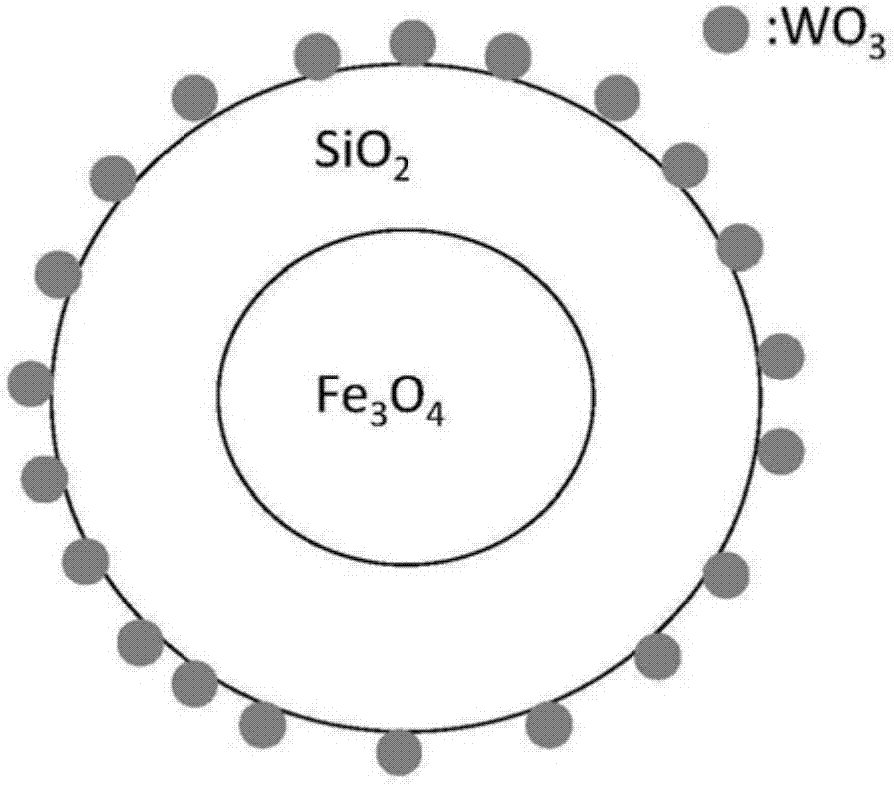

[0039] Preparation of Magnetic Separation Core-Shell Supported Tungsten Composite Catalyst WO 3 / SiO 2 / Fe 3 O 4 The preparation method is carried out according to the following steps in turn:

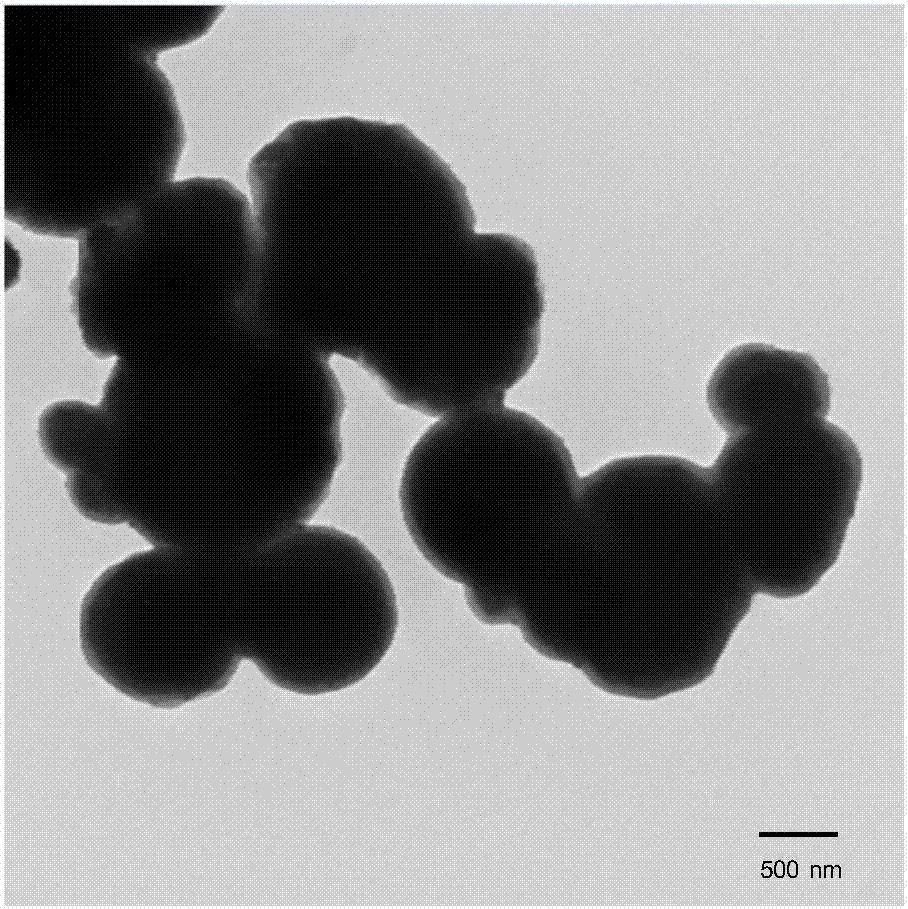

[0040] 1), the preparation of Fe 3 O 4 Nanoparticles

[0041] Preparation of Fe by Partial Reduction-Coprecipitation 3 O 4Nanoparticles. 16.3 g FeCl at room temperature 3 Add to 250 mL flask and dissolve with water. Under the protection of nitrogen, slowly add the reducing agent Na 2 SO 3 Solution (containing 2.7g Na 2 SO 3 ) and stirring, and 40.8 mL of ammonia water with a mass fraction of 28% was quickly added after 10 minutes, and the formation of black particles was observed. The temperature of the constant temperature water bath was raised to 70 °C, and 2 mL of oleylamine was added as a surfactant, and the stirring was continued for 6 hours. After that, the product was centrifuged and washed with deionized water for several times. Finally, the ionized water was disp...

Embodiment a1-a12

[0049] Embodiment a1-a12: the preparation method of quinolones

[0050] Put 24.6g ethyl formyl ethyl acetate sodium salt, 100mL toluene and 4g WO into the reactor 3 / SiO 2 / Fe 3 O 4 Catalyst, feed 8.7g dimethylamine under stirring, add 10g 2,4-dichloro-5-fluorobenzoyl chloride, keep the reaction for 1 hour, add cyclopropylamine dropwise at 50°C, and feed CO at the same time 2 , the control reaction pressure is 1.5-2 atmospheres. After reacting for 1 hour, 12 g of flake alkali and 200 mL of toluene were added to the reaction solution, and the temperature was raised to 100° C. with stirring, kept for half an hour, the catalyst was recovered by filtration, and the toluene was recovered under pressure to dryness. Add an appropriate amount of water, heat up to 100°C, and after the system is clarified, add hydrochloric acid dropwise to adjust the pH, and after the crystals are precipitated, centrifuge and dry to obtain the organic amine compound of formula (V).

[0051] Embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com