A kind of method that vacuum energy prepares sponge body graphene

A technology of sponge and graphene, applied in the direction of graphene, single-layer graphene, chemical instruments and methods, etc., can solve the problems of difficult preparation of single-layer graphene, low efficiency of chemical growth method, high energy consumption of production method, etc. problem, to achieve the effect of good dispersion, large capacity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Send the graphite rod into the reaction chamber of the vacuum reactor, and use an arc with a temperature of 12000°C to ionize the graphite rod in a vacuum environment to obtain graphene in the inner wall area of the reaction chamber. The arc-releasing device may have an input voltage of 55V and an input current of 4A during discharge; the frequency of the input power may be 40hz.

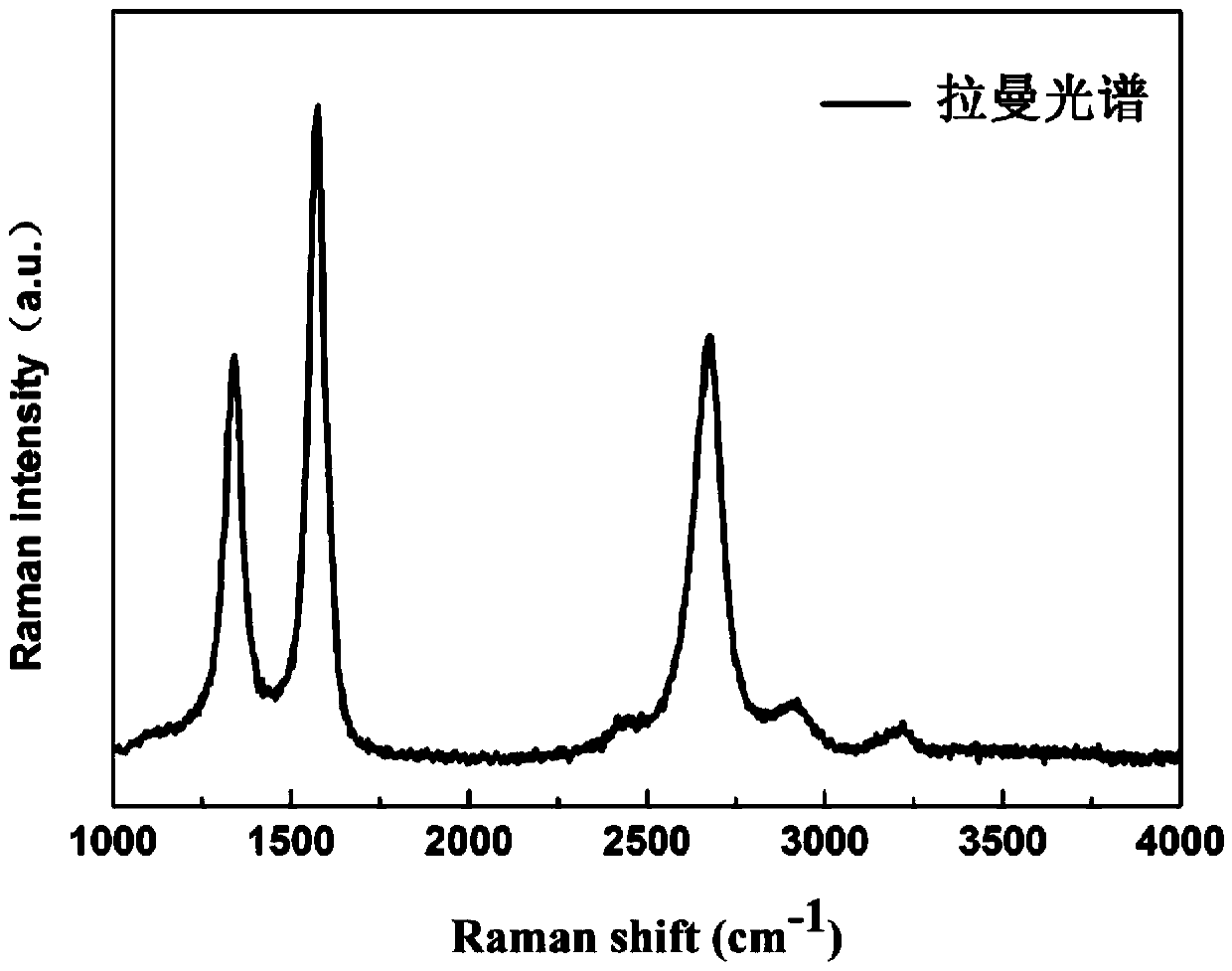

[0019] 1. Raman test is carried out on the obtained graphene, the result is as follows figure 1 shown, from figure 1 It can be seen that the graphene in this embodiment is highly symmetric and highly ordered single-crystal graphite with extremely high purity, and the graphene basically only has a single 2D peak, indicating that the graphene is completely exfoliated into a single sheet of graphene.

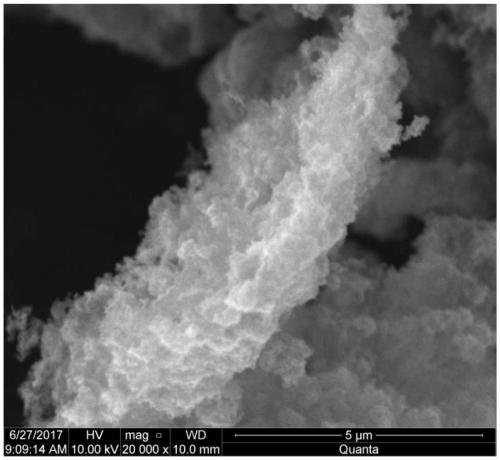

[0020] 2. Scanning the obtained graphene with a transmission electron microscope, the results are as follows: figure 2 shown. from figure 2 It can be seen that when zooming in at 1.2K, lar...

Embodiment 2

[0029] Send the graphite rod into the reaction chamber in the vacuum reactor, and in a vacuum environment, use an arc with a temperature of 10,000°C to ionize the graphite rod to obtain graphene in the inner wall area of the reaction chamber; the discharge voltage of the arc is The discharge current is 50V, and the discharge current is 3A; the electric frequency during discharge is 30hz.

[0030] The graphene obtained is identified as sponge graphene by the method in Example 1.

Embodiment 3

[0032] The graphite rod is sent into the reaction chamber in the vacuum reactor, and under the vacuum environment, the graphite rod is ionized by an electric arc with a temperature of 13000° C., and a single-layer graphene is obtained in the inner wall area of the reaction chamber; The discharge voltage is 60V, the discharge current is 5A; the frequency of electricity during discharge is 45hz.

[0033] The graphene obtained is identified as sponge graphene by the method in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com