Normal-pressure cationic dyeable polyester and production method and purpose thereof

A technology of cationic dye and production method, applied in the field of normal pressure cationic dye-dyeable polyester and its production and use, can solve the problems of poor heat resistance and low melting point of polyester, and achieve good heat resistance and thermal stability The effect of high sex and low diethylene glycol content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

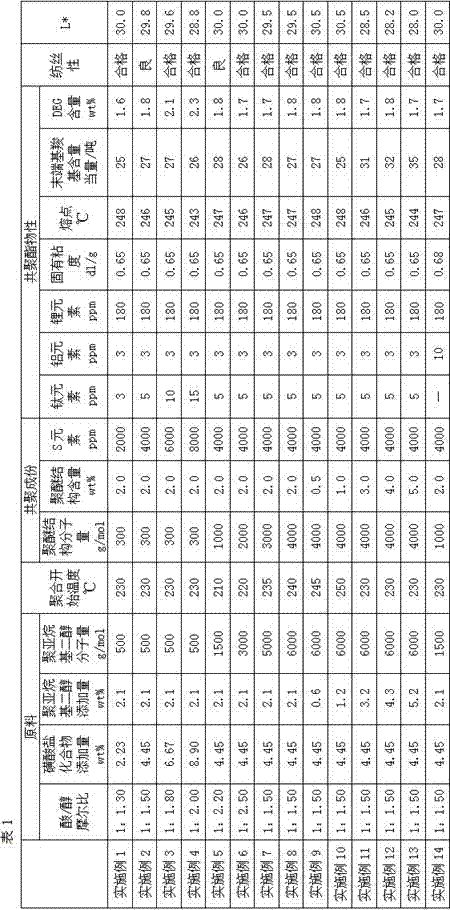

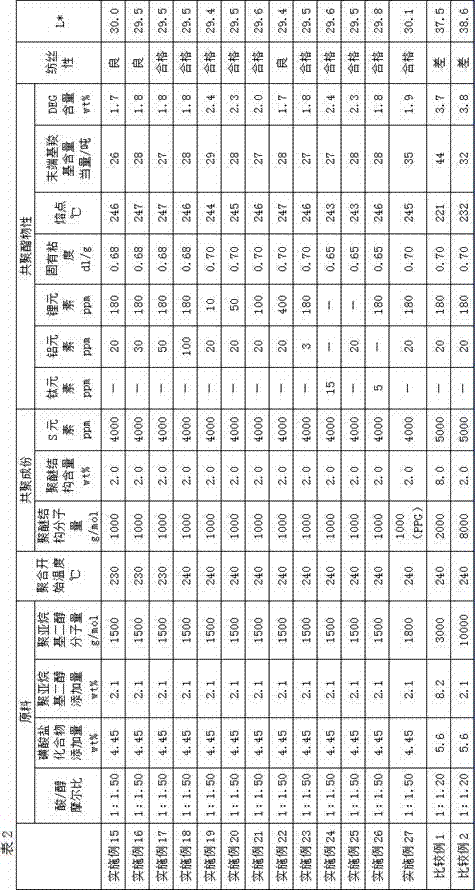

Embodiment 1

[0056] Add 13,000g of PTA (purified terephthalic acid) and 8,600g of EG (ethylene glycol) into the esterification kettle, and stir and react at 250°C for 5 hours; through the judgment of by-products, the esterification reaction rate reaches 97% Above, move the prepared BHT oligomer into the polymerization kettle; add EG first, adjust the molar ratio of EG and PTA in BHT to 1.30:1, stir for 30 minutes and add the stabilizer phosphorus compound trimethyl phosphate; then add Ethylene glycol isophthalate-5-sodium sulfonate (SIPE) 855g, polyethylene glycol (PEG500) with a number average molecular weight of 500g / mol 305g, catalyst tetrabutyl titanate (TBT) 2.5g, aluminum compound (A2E: Toyobo Co., Ltd. aluminum-based catalyst) catalyst 25g, catalyst lithium acetate (LAH) 240g. Subsequently, the pressure was reduced and the temperature was raised at 230°C, and the conventional polyester polycondensation method was used for polymerization to obtain a cationic dyeable copolymer under n...

Embodiment 2

[0068] The molar ratio of EG and PTA in BHT was adjusted to 1.50:1, the content of sulfur element in polyester was 4000ppm, and the content of titanium element was 5ppm. Others were the same as in Example 1, as shown in Table 1. Polyester will not break during the spinning process, and its fiber fabric has good dyeability.

Embodiment 3

[0070] The molar ratio of EG and PTA in BHT was adjusted to 1.80:1, the content of sulfur element in polyester was 6000ppm, and the content of titanium element was 10ppm. Others were the same as in Example 1, as shown in Table 1. Polyester will not break during the spinning process, and its fiber fabric has good dyeability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com