Functionalized/thermally reversible crosslinked epichlorohydrin rubber and preparation method thereof

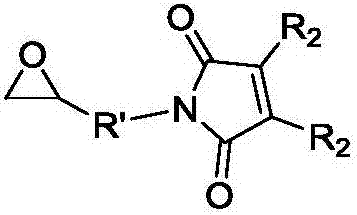

The technology of chloroether rubber and chloroethene is applied in the field of thermally reversible cross-linked chloroether rubber and its preparation, which can solve problems such as environmental pollution and achieve the effects of high reactivity, easy regulation and control of structure and composition, and simple and efficient preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1, the preparation method of alkylaluminum catalyst

[0020] Under the protection of dry inert gas argon or nitrogen, add triisobutylaluminum (1.0 mmol) toluene solution and phosphoric acid (0.35 mmol) ether solution into the dry deoxygenated reactor, stir at 0°C for 30 minutes, and then Add 1,8-diazabicycloundec-7-ene (DBU, 0.26mmol), stir and react at 40°C for 3 hours to obtain a catalyst for the synthesis of furan and maleimide functionalized polyether materials solution.

Embodiment 2

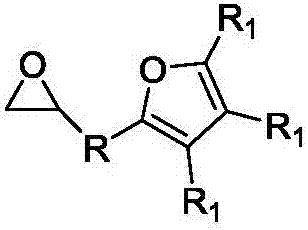

[0021] Embodiment 2, preparation of furan functionalized chloroether rubber

[0022] Under the protection of dry inert gas argon or nitrogen, add 10ml of toluene, 1.6g of epichlorohydrin, 0.2g of ethylene oxide, and 0.2g of glycidyl furfuryl ether into the dry deoxygenated polymerization reactor, and mix thoroughly Then add the catalyst prepared by the method in Example 1, wherein triisobutylaluminum (0.5mmol) toluene solution and phosphoric acid (0.15mmol) ether solution were reacted at 0°C for 30min, and then DBU (0.12mmol) was added to react at 60°C for 2h; The polymerization reaction solution was stirred and reacted at 60° C. for 2 hours. After the reaction, the polymer was dried by a traditional post-treatment method to obtain 2.0 g of furan-functionalized epichlorohydrin rubber with a conversion rate of 100%. The structure and properties of the product are analyzed as follows: the number average molecular weight is 140,000, the molecular weight distribution is 1.6, and t...

Embodiment 3

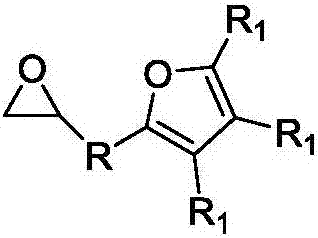

[0023] Embodiment 3, preparation of furan functionalized chloroether rubber

[0024] Under the protection of dry inert gas argon or nitrogen, add toluene 10ml, epichlorohydrin 0.64g, oxirane 0.35g, 2-((3-(oxirane- 2 (M) propyl) thio) methyl) furan 0.01g, add the prepared catalyst after thorough mixing, wherein the catalyst is composed of triisobutylaluminum (0.5mmol) toluene solution and phosphoric acid (0.175mmol) ether solution in React at 0°C for 30 minutes, then add DBU (0.13mmol) and react at 60°C for 2h; the polymerization reaction liquid is stirred and polymerized at 40°C for 2h, and after the reaction is completed, the polymer is dried by a traditional post-treatment method to obtain a furan-functionalized chloroether Rubber 1.0g, conversion rate 100%. The structure and properties of the product are analyzed as follows: the number average molecular weight is 70,000, the molecular weight distribution is 1.5, and the glass transition temperature is -40°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com