Application of ethylene maleic anhydride alternating copolymer and hydrolysate thereof in preparation of silicon negative electrode material

A technology of alternating copolymer and maleic anhydride, used in battery electrodes, circuits, electrical components, etc., can solve the problems of poor performance and volume change of silicon anode electrode materials, and achieve easy control of electrode structure and performance, increase content, and improve The effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This embodiment provides an ethylene maleic anhydride alternating copolymer / silicon powder / conductive carbon black negative electrode.

[0050] Put silicon powder: conductive carbon black at a mass ratio of 6:2 into a ball mill jar, and use a ball mill to mill at a speed of 450rp for 30 minutes to obtain a silicon powder / conductive carbon black composite material. 20 parts of ethylene maleic anhydride alternating copolymer (Sigma-Aldrich, M w =100000~500000, CAS: 9006-26-2) was dissolved in 200 parts of N-methylpyrrolidone, 80 parts of silicon powder / conductive carbon black composite material was added, and fully stirred to obtain a silicon-based composite slurry. The composite slurry was coated on copper foil, dried in vacuum at 80° C. for 24 h, and sliced into silicon negative electrodes.

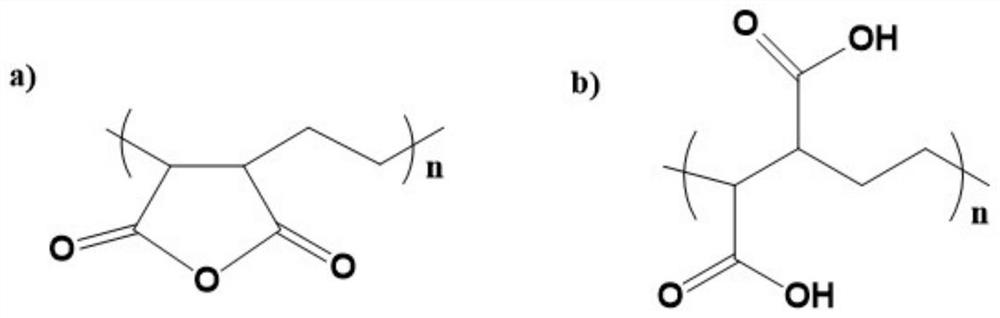

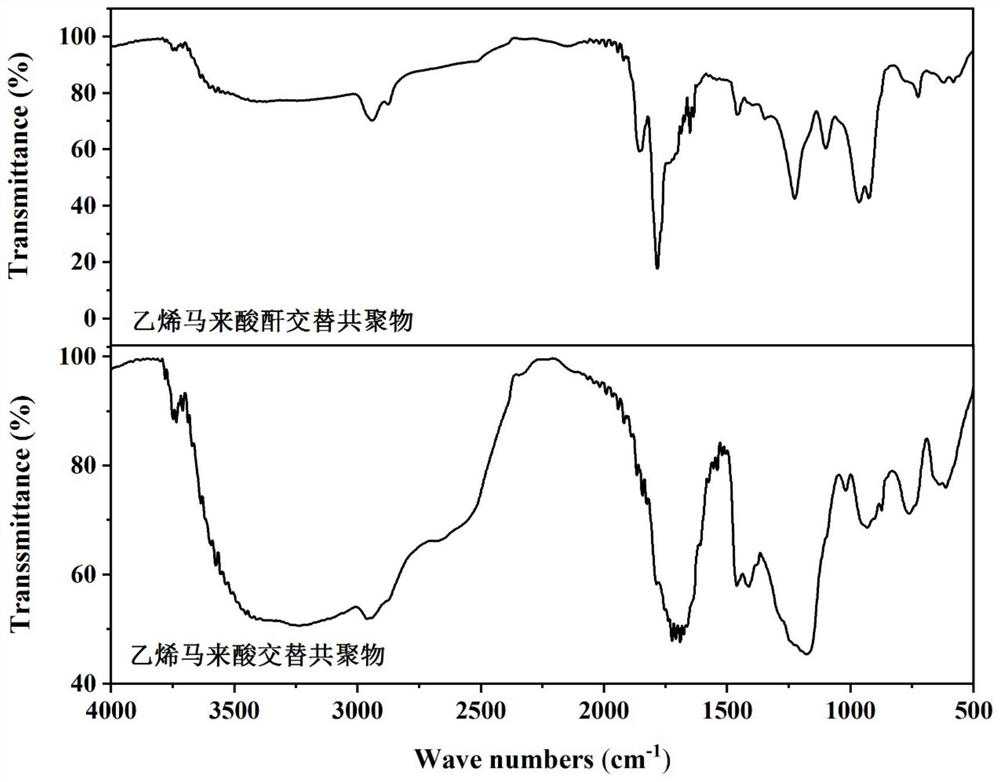

[0051] The structure of the ethylene maleic anhydride alternating copolymer in embodiment 1 is as figure 1 (a) shown.

[0052] Thermo Nicolet Nexus 670 infrared spectrometer w...

Embodiment 2

[0055] This embodiment provides ethylene maleic acid alternating copolymer and a negative electrode of ethylene maleic acid alternating copolymer / silicon powder / conductive carbon black.

[0056] Add 1g of ethylene-maleic anhydride alternating copolymer and 100mL of ultrapure water in a 250mL flask, heat and stir in a water bath at 80°C; after 3 hours of reaction, the mixed solution becomes clear and transparent, and the maleic anhydride alternating copolymer is obtained by drying and removing water. The hydrolysis product of the copolymer, that is, ethylene-maleic acid alternating copolymer.

[0057] Dissolve the above 20 parts of ethylene-maleic acid alternating copolymer in 200 parts of ultrapure water, then add 80 parts of the silicon powder / conductive carbon black composite material prepared in Example 1, and stir thoroughly to obtain a silicon-based composite slurry. The composite slurry was coated on copper foil, dried in vacuum at 80° C. for 24 h, and sliced into sili...

Embodiment 3

[0063] This embodiment provides a flexible self-supporting ethylene maleic anhydride alternating copolymer / nano silicon powder / carbon nanotube negative electrode.

[0064] Dissolve 20 parts of ethylene maleic anhydride alternating copolymers in Example 1 in 750 parts of N-methylpyrrolidone, add 20 parts of single-walled carbon nanotubes and 60 parts of nano silicon powder under ultrasonic stirring conditions, and mix thoroughly to obtain Homogeneous ethylene maleic anhydride alternating copolymer / nano silicon powder / carbon nanotube composite material, poured into a glass mold, and after the organic solvent evaporates, a specific shape of ethylene maleic anhydride alternating copolymer / nano silicon powder / A carbon nanotube composite electrode material, which can be cut to obtain a negative electrode.

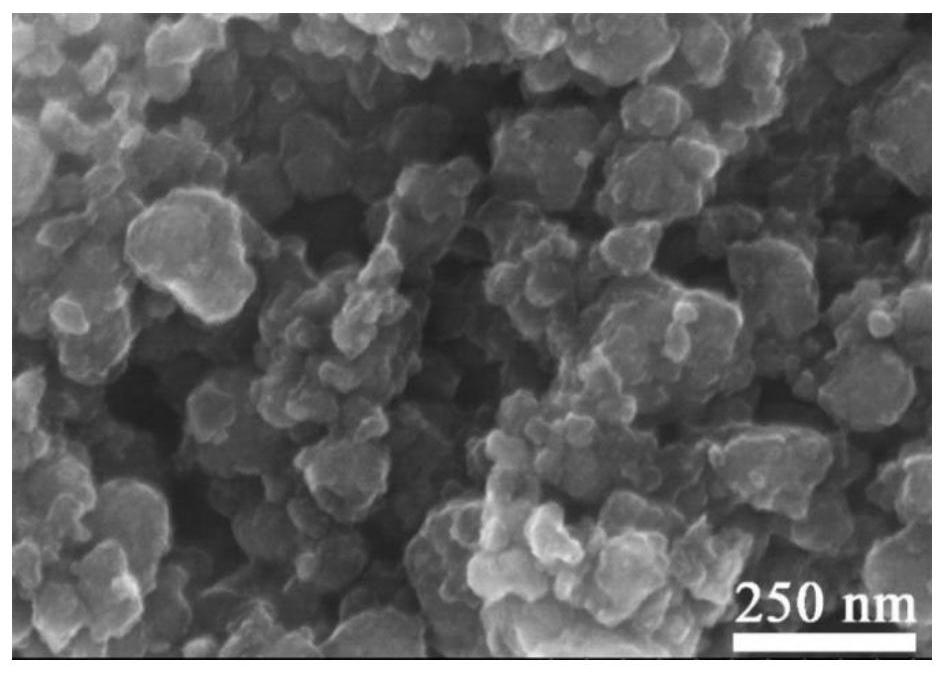

[0065] The ethylene maleic anhydride alternating copolymer, nanometer silicon powder and carbon nanotubes in the composite electrode material form a three-dimensional ternary co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com