Preparation method of silicon-oxygen-carbon type lithium ion battery negative electrode material

A technology of silicon oxygen carbon lithium and ion batteries, applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effects of high cycle stability, easy industrial preparation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A preparation method of a silicon oxygen carbon type lithium ion battery negative electrode material, comprising the following steps:

[0024] 1) reacting vinyl-containing compounds with PCS in different proportions to regulate the Si-C ratio; in step 1), the vinyl-containing compounds can be selected from styrenes, divinylbenzenes, methacrylic acid One of vinyl compounds such as esters and acrylates; the specific method of reacting vinyl-containing compounds and PCS in different proportions to regulate the ratio of Si-C can be: use a Pt-containing catalyst to catalyze vinyl and Si The addition reaction of -H bond, by adjusting the feed ratio of vinyl compound and PCS, control Si x o y C z The ratio of Si and C of the ceramic; the mass ratio of the vinyl compound: PCS is 0.05-1.

[0025] 2) reacting the product of step 1) and the metal organic compound in different proportions; in step 2), the metal organic compound can be one of carbonyl metal organic compounds, ace...

Embodiment 1

[0030] 1) Grind 1.0g of PCS into powder, place it in a tube furnace, pass in air, first raise the temperature to 100°C at 5°C / min, then raise the temperature to 160°C at 10°C / h, keep it warm for 20 hours and then cool with the furnace;

[0031] 2) Put 1.0 g of the polycarbosilane obtained in step 1) in a tube furnace, raise the temperature to 1300° C. at 180° C. / h under an Ar atmosphere, keep it warm for 1 hour, and then cool it with the furnace to obtain a silicon oxygen carbon ceramic.

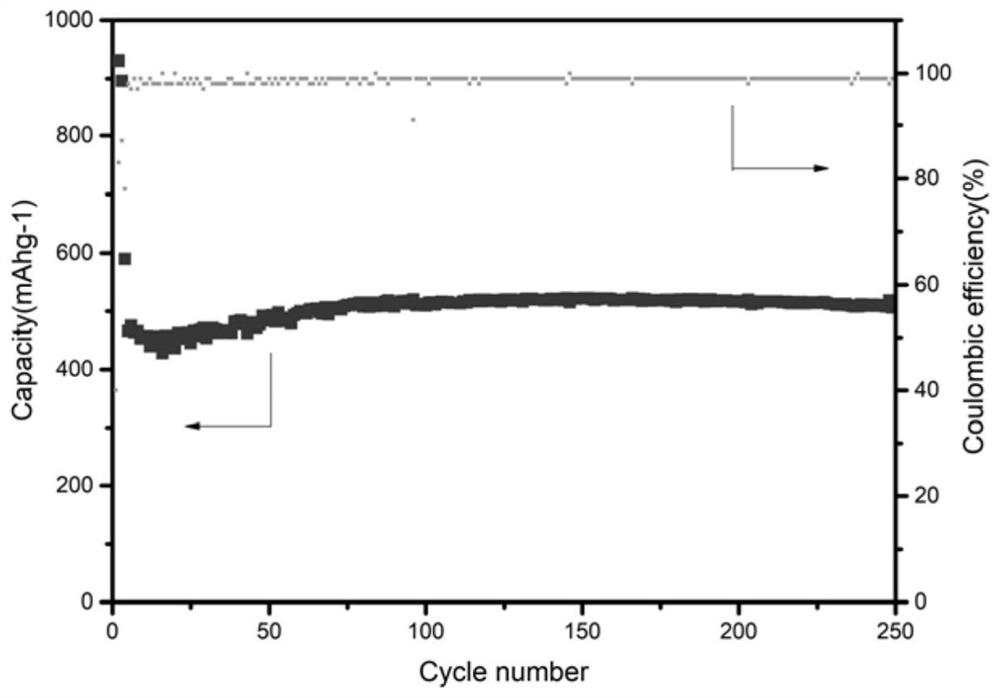

[0032] figure 1 The cycle performance diagram of the button-type half-cell assembled from the silicon-oxygen-carbon ceramics obtained in Example 1.

Embodiment 2

[0034] 1) React 5.0g PCS, 0.5g divinylbenzene, 100μL 10% chloroplatinic acid isopropanol solution and 100mL n-hexane under an inert atmosphere at 70°C for 24h, remove n-hexane after the reaction, and dry at 50°C under vacuum 24h to obtain divinylbenzene modified PCS.

[0035] 2) Place the product obtained in step 1) in a tube furnace, feed air, first raise the temperature to 100°C at 5°C / min, then raise the temperature to 200°C at 10°C / h, keep it warm for 3 hours and then cool with the furnace;

[0036] 3) The sample obtained in step 2) was placed in a tube furnace, and the temperature was raised to 900°C at 120°C / h under Ar atmosphere, kept for 1h, and then cooled with the furnace to obtain silicon oxygen carbon ceramics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com