Phase change thermal insulation paint and preparation method thereof

A heat insulation and coating technology, applied in the field of coatings, can solve the problems that the internal temperature of the coated object cannot be kept at a constant temperature, and achieve the effects of excellent protection and decoration, good economic benefits, excellent weather resistance and decorative protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

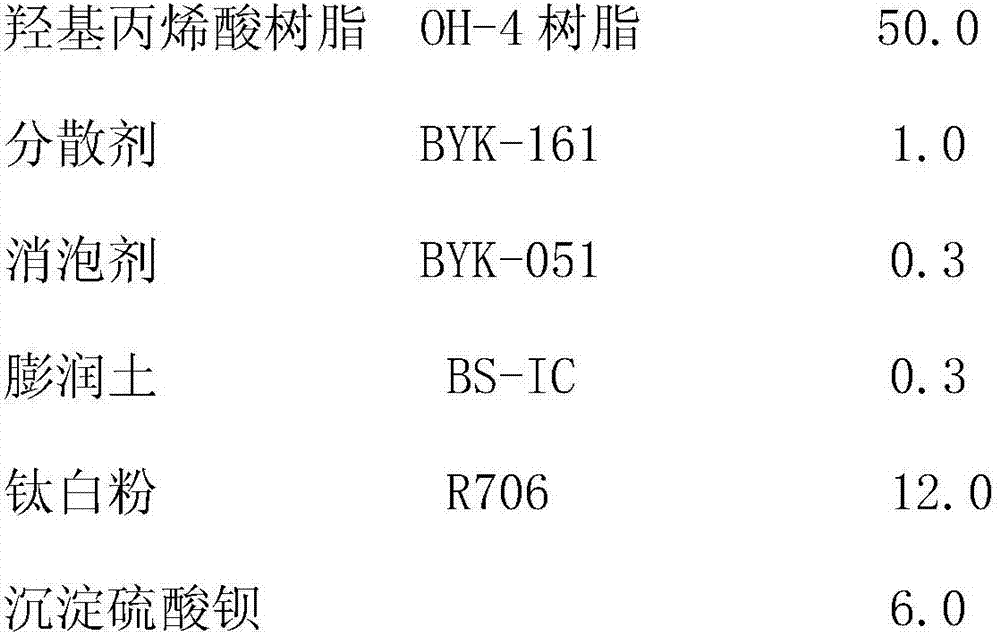

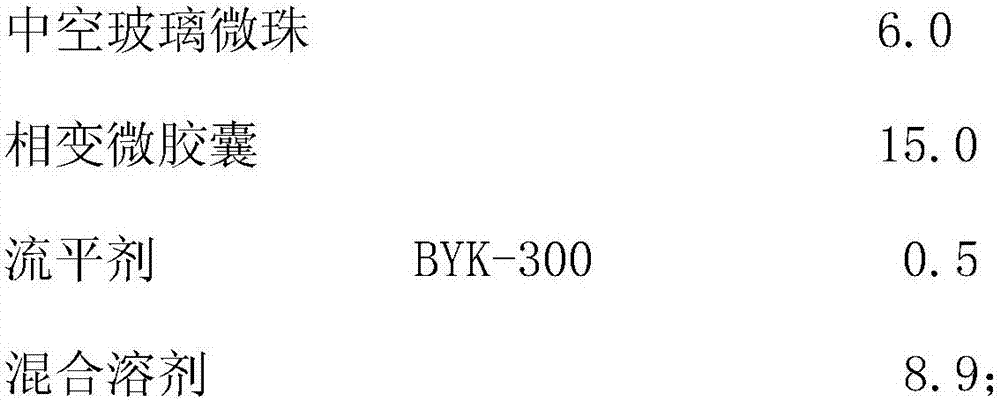

[0036] A phase-change thermal insulation coating, the coating is composed of a main agent and a curing agent, the mass ratio of main raw materials is the main agent: curing agent = 100:20;

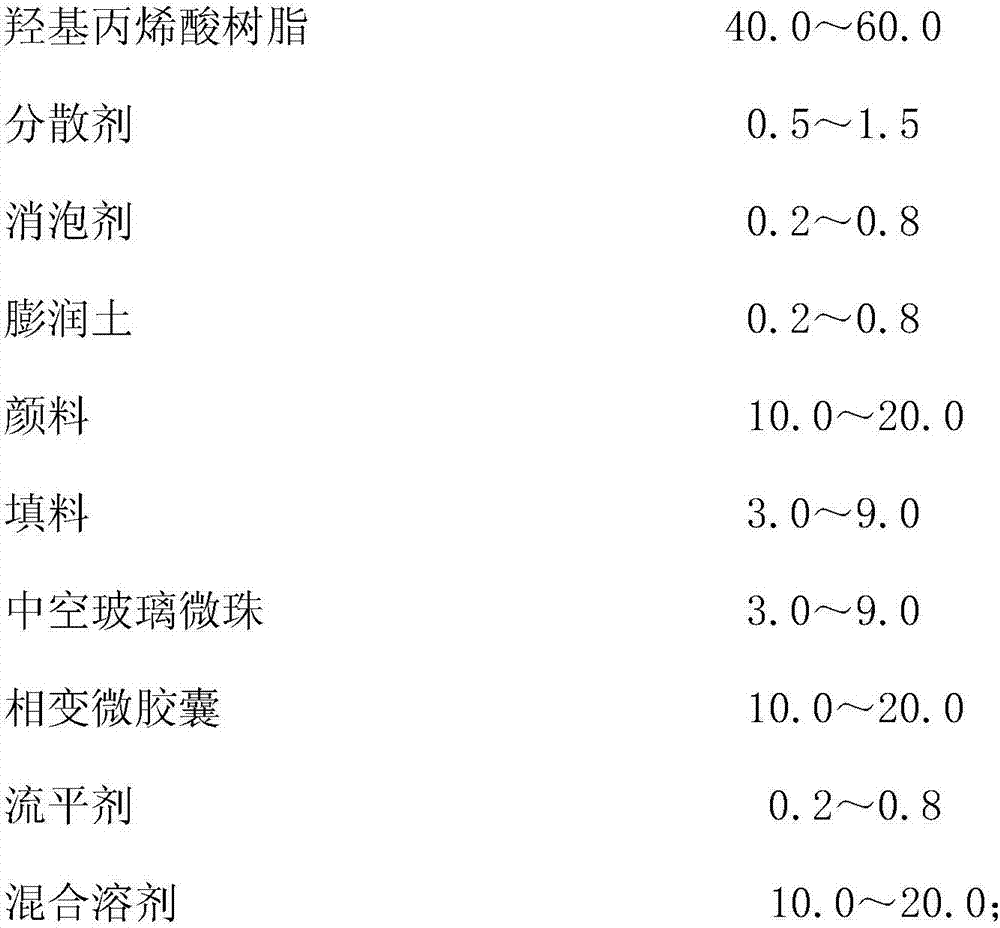

[0037] The main ingredient includes the following raw materials in parts by mass:

[0038]

[0039]

[0040] Curing agent comprises the raw material of following mass parts:

[0041] Aliphatic polyisocyanate resin N3390 55.0

[0042] Anhydrous butyl acetate 45.0;

[0043] Mixed solvent comprises the raw material of following mass parts:

[0044] Butyl acetate 25.0

[0045] Xylene 65.0

[0046] Propylene glycol methyl ether acetate 10.0.

[0047] A preparation method of a phase change thermal insulation coating, comprising the following steps:

[0048] A preparation of mixed solvent

[0049] (1), add 25.0 parts of butyl acetate, 65.0 parts of xylene and 10.0 parts of propylene glycol methyl ether acetate into the batching tank, stir while adding, fully stir the above materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com