Umbrella tower type photobioreactor

A photobioreactor and tower technology, applied in the field of umbrella-shaped tower photobioreactor, can solve the problem of less research on automatic adjustment, and achieve the effects of convenient movement and fixation, increased mobility, and saving water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

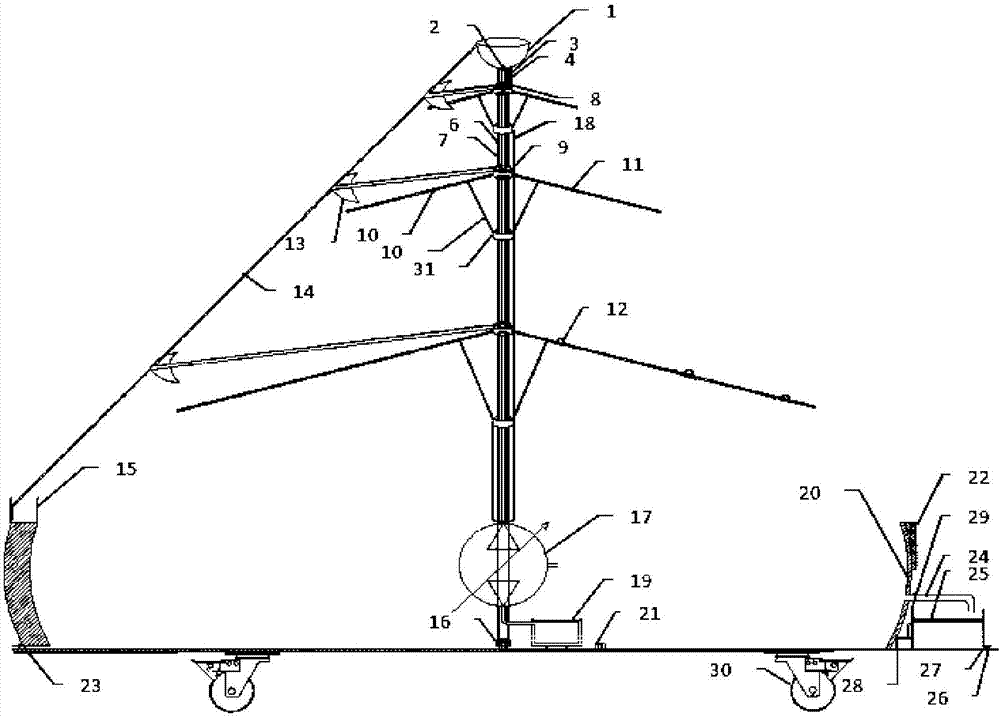

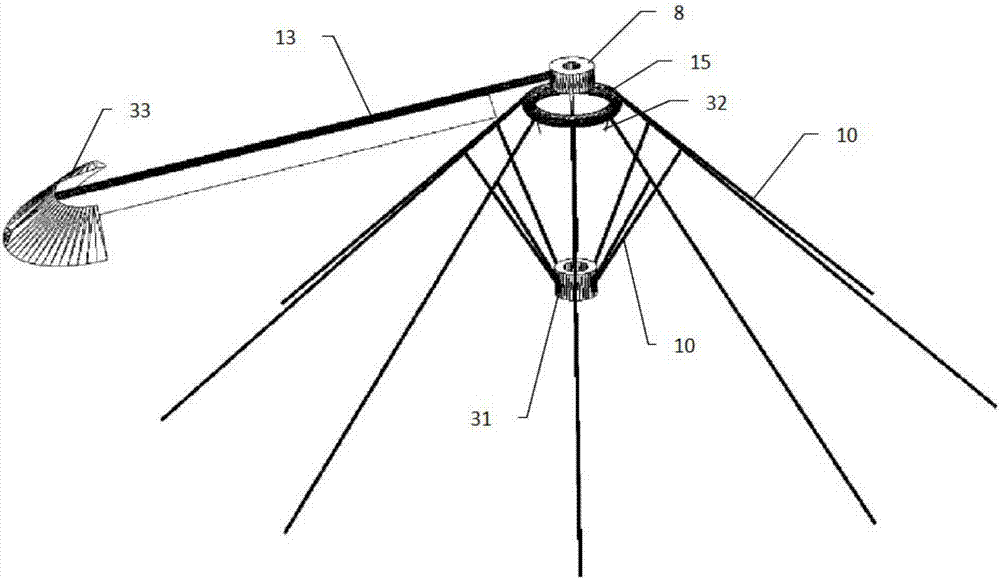

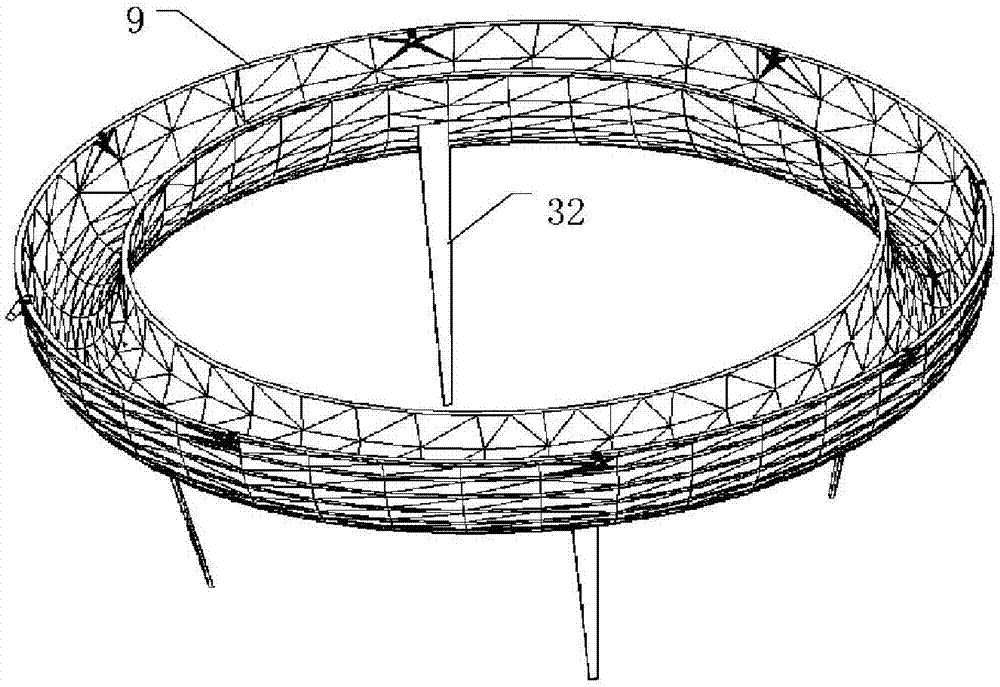

[0034] The specific implementation of the invention will be further described below in conjunction with the drawings.

[0035] Such as Figure 1-3 As shown, the culture solution tank 20 has a reflective layer on its inner wall for holding the culture solution inoculated with microalgae. The culture solution tank 20 is in the shape of a "bowl", the inner surface of which is coated with a total reflection mirror film or pasted with tin foil, the side wall of the "bowl" is inclined; its bottom surface is provided with a universal wheel 30 for walking. A water inlet 23 is provided at the bottom of the culture solution tank 20. The side wall and bottom of the "bowl-shaped" have a certain inclination angle, and the light source is projected into the light guide plate 11 and the culture medium suspended at the low end through the specular reflection and diffuse reflection of the side wall and the low end, and the light source is fully utilized. The culture medium tank 20 is Polymer tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com