Microcrystal inorganic heat preservation and decoration integrated plate

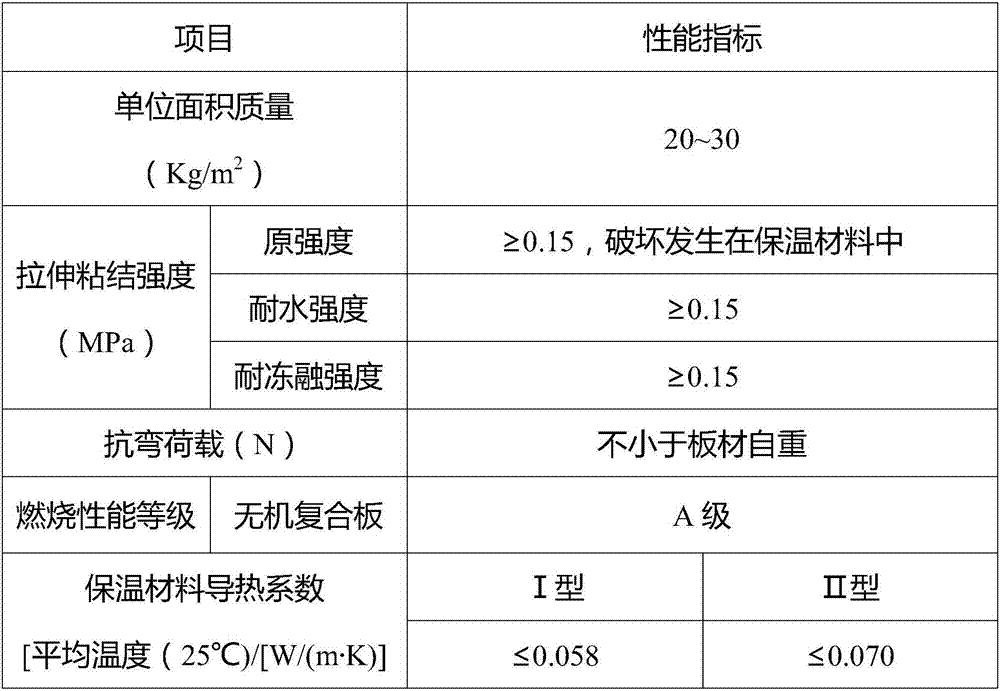

An inorganic thermal insulation and integrated board technology, which is applied in coatings, building components, layered products, etc., can solve the problem of delamination of decorative panels and insulation layers, low strength of expanded perlite, poor water resistance and freeze-thaw resistance, etc. Problems, to achieve the effect of no shrinkage and deformation, low strength, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] To prepare the microcrystalline inorganic thermal insulation and decorative integrated board, first prepare the inorganic gelling material, add 100kg of cement, 10kg of redispersible latex powder, 1kg of cellulose ether, 2kg of polyvinyl alcohol, 3kg of modified polyethylene oxide, and organic Silicone 0.4kg, polypropylene fiber 1kg, fully stirred to prepare inorganic gelling material;

[0026] Prepare modified expanded perlite, quantitatively and automatically transport the prepared inorganic gelling material to the semi-finished product mixing equipment of expanded perlite, add 50kg of water, 30kg of expanded perlite and 18kg of the inorganic gelling material prepared above to the mixing system. Fully stir until the inorganic gelling material wraps every expanded perlite particle,

[0027] Slurry is coated on the back of the ceramic panel, and the commercially available ceramic panel (the ceramic panel of the specification of 600mm*900mm is selected in this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com