Spring test probe

A technology for testing probes and torsion springs, which is applied in the direction of measuring electricity, measuring devices, and measuring electrical variables. It can solve problems such as unfavorable data accuracy acquisition, poor contact, and impact on test accuracy, so as to reduce the shading area, avoid sliding wear, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

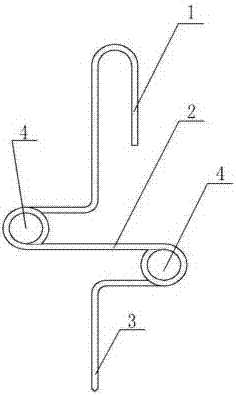

[0011] The spring test probe of the present invention is used to test the electrical properties of solar cells, the spring test probe is an integrally formed structure, and a linear connector 1, a buffer part 2 and a contact 3 are arranged in sequence from top to bottom, The buffer part 2 is a two-stage spring system, the basic spring of which is a coil of torsion spring 4 . The linear connector 1 , the torsion spring 4 of the buffer part, and the contact 3 of the probe described in this embodiment are all rings with equal diameters, with a diameter of 0.5 mm. The two-stage spring system based on the torsion spring in this embodiment has a better buffering effect between the connector 1 and the contact 3. It is flexible, not easy to damage, and has strong repairability, which can effectively prevent the spring from repeating. Plastic deformation under pressure.

[0012] When in use, install the probe on the test device, adjust the position, align it with the main grid line of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com