Buffalo feed as well as preparation method and application thereof

A feed and water buffalo technology, which is applied in the field of buffalo breeding, can solve problems such as not being able to meet the growth needs of young cattle, and achieve the effects of enhancing animal immunity, improving digestion, and improving the taste of feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

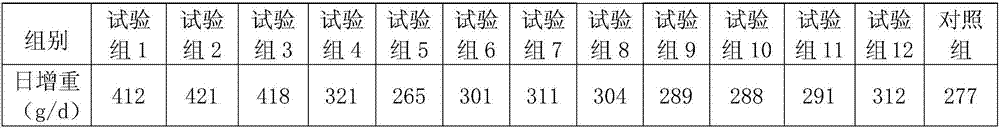

Examples

Embodiment 1

[0022] The feed of the present embodiment is composed of basal diet and feed additive according to the mass ratio of 50:1;

[0023] Wherein, the basal diet consists of the following raw materials in parts by weight: 34 parts of fermented alfalfa, 13 parts of corn stalks, 42 parts of fermented straw and 11 parts of soybean meal;

[0024] Wherein, the feed additive is made up of the raw material of following parts by weight: 15 parts of chitosan, 12 parts of seaweed, 1 part of betaine, 3 parts of yeast chromium, 11 parts of yeast selenium, 13 parts of wort, 7 parts Poria cocos extract.

[0025] In this example, the fermentation method for fermenting alfalfa is as follows: crush the alfalfa and mix it evenly with activated probiotics at a weight ratio of 27:1, then ferment for 21 days at a temperature of 26°C and a humidity of 8%. After the end, the alfalfa is put into the drying room for drying until the moisture content is 7% to obtain fermented alfalfa; the fermentation metho...

Embodiment 2

[0035] The feed of the present embodiment is composed of basal diet and feed additive according to the mass ratio of 55:1;

[0036] Wherein, the basal diet consists of the following raw materials in parts by weight: 43 parts of fermented alfalfa, 19 parts of corn stalks, 47 parts of fermented straw and 17 parts of soybean meal;

[0037] Wherein, the feed additive is made up of the raw material of following weight part: the chitosan of 24 parts, the seaweed of 26 parts, the betaine of 5 parts, the yeast chromium of 8 parts, the yeast selenium of 21 parts, the wort juice of 21 parts, the wort of 17 parts Poria cocos extract.

[0038] In this example, the fermentation method for fermenting alfalfa is: crushing alfalfa and uniformly mixing with activated probiotics at a weight ratio of 33:1, then fermenting for 25 days at a temperature of 30°C and a humidity of 12%. After the end, the alfalfa is put into the drying room for drying until the moisture content is 10% to obtain ferme...

Embodiment 3

[0048] The feed of the present embodiment is composed of basal diet and feed additive according to the mass ratio of 52:1;

[0049] Wherein, the basal diet consists of the following raw materials in parts by weight: 40 parts of fermented alfalfa, 17 parts of corn stalks, 45 parts of fermented straw and 14 parts of soybean meal;

[0050] Wherein, the feed additive is made up of the following raw materials by weight: 19 parts of chitosan, 19 parts of seaweed, 3 parts of betaine, 5 parts of yeast chromium, 17 parts of yeast selenium, 17 parts of wort, 10 parts Poria cocos extract.

[0051] In this example, the fermentation method for fermenting alfalfa is as follows: crush the alfalfa and evenly mix it with activated probiotics at a weight ratio of 29:1, then ferment for 22 days at a temperature of 28°C and a humidity of 10%. After the end, the alfalfa is put into the drying room for drying until the moisture content is 8% to obtain fermented alfalfa; the fermentation method of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com