Integrated anaerobic ammonia oxidation reinforced endogenous denitrification SBBR advanced nitrogen removal method

A technology of anaerobic ammonia oxidation and endogenous denitrification is applied in the field of integrated anammox to strengthen endogenous denitrification SBBR deep denitrification, which can solve the problem of high energy consumption, low carbon-nitrogen ratio and poor denitrification process effect. and other problems, to achieve the effect of high biological activity, easy control, saving carbon source and aeration amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

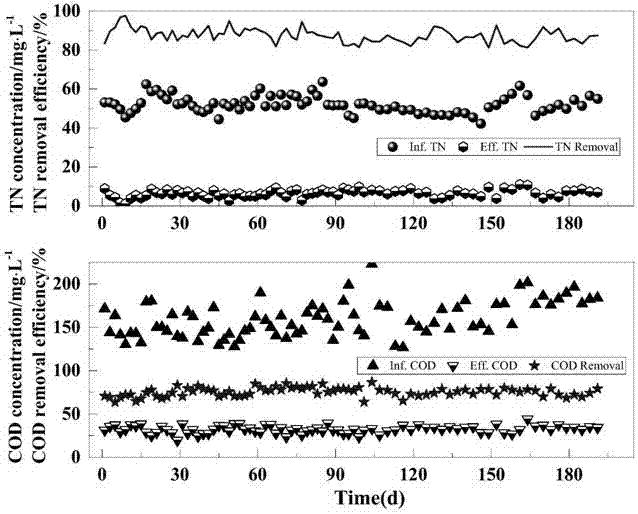

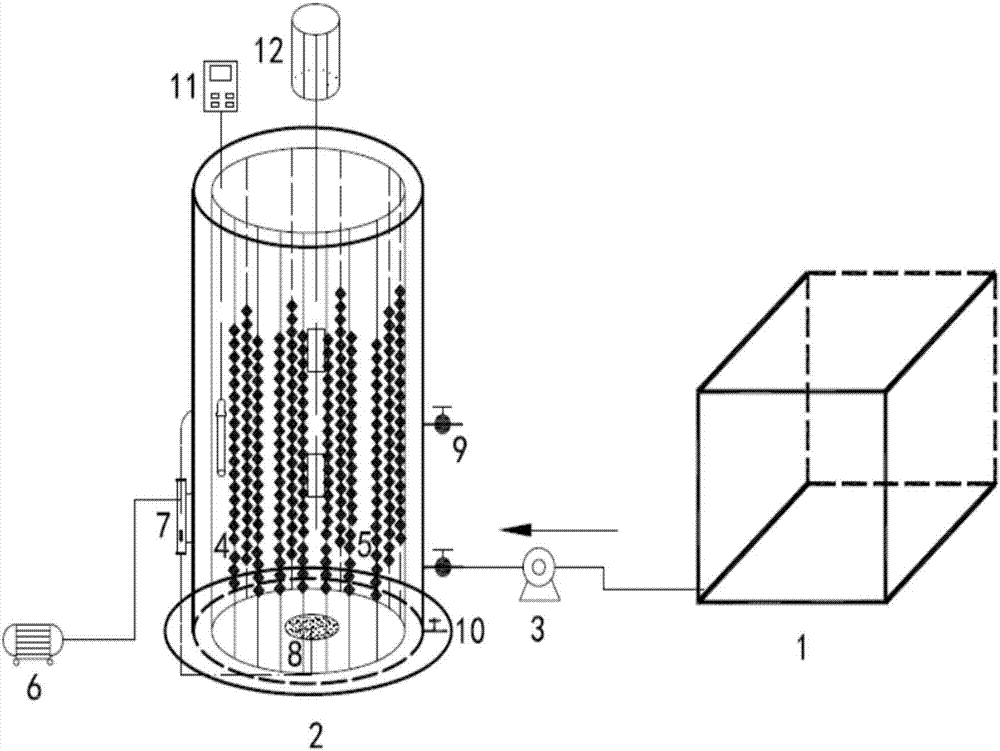

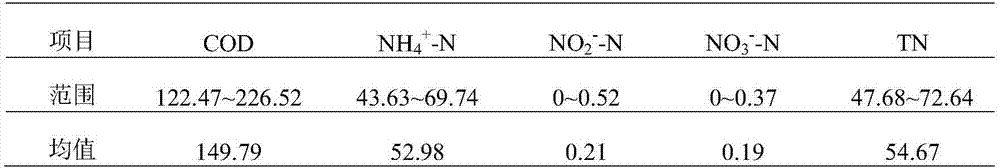

[0023] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0024] Such as figure 1 As shown, the integrated anaerobic ammonium oxidation enhanced endogenous denitrification deep denitrification SBBR system mainly includes domestic sewage water tank (1) and SBBR reactor (2). The main body of the SBBR reactor (2) is made of plexiglass, with an effective volume of 10L. The domestic sewage water tank (1) is connected with the SBBR reactor (2) through the water inlet pump (3); the SBBR reactor (2) is provided with a filler bracket (4), a biological filler (5), an air pump (6) , gas flow meter (7), aeration disc (8), drain valve (9), sludge discharge valve (10), DO probe (11), agitator (12); the biological filler (5) is cubic , the material is polyurethane, the porosity is greater than 90%, and the specific surface area is 20-23m 2 / g, with a filling rate of 20% to 25%, hang it on the filler support ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com