Sweet corn syrup lactic acid bacteria beverage and preparation method thereof

A lactic acid bacteria beverage, sweet corn technology, applied to bacteria, lactobacilli, food ingredients and other directions used in food preparation, can solve problems such as increased enzyme cost, loss of nutrients, reduced corn flavor, etc., and reduce the content of residual starch. , to promote degradation and utilization, the effect of fine texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

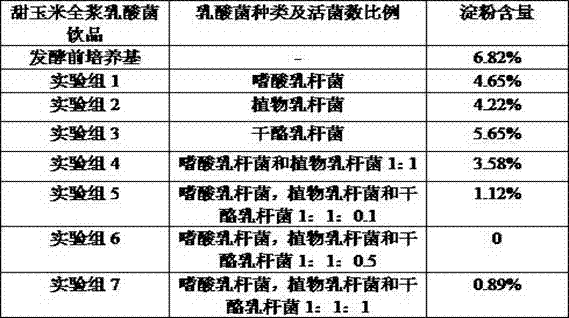

Image

Examples

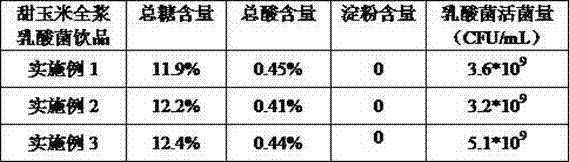

Embodiment 1

[0032] A sweet corn whole milk lactic acid bacteria beverage is prepared through the following steps:

[0033] (1) Washing the fresh sweet corn, threshing, and discarding the corn cob to obtain fresh corn kernels;

[0034] (2) Add fresh corn kernels and purified water into a colloid mill at a mass ratio of 1:1, and crush and homogenize to obtain fresh corn steep liquor;

[0035] (3) Add an appropriate amount of water into the fermenter, and mix fresh corn steep liquor, brown sugar, glucose, whey powder, and K 2 HPO 4 、KH 2 PO 4 , MgSO 4 Add it into the tank, stir to dissolve and then constant volume to obtain the fermentation medium, in which the final mass-volume ratio of each component is: fresh corn steep liquor 10%, brown sugar 6%, glucose 5%, whey powder 0.02%, K 2 HPO 4 0.03%, KH 2 PO 4 0.02%, MgSO 4 0.03%; the initial pH value of the medium is 5.5-6.5; use high-temperature steam to control the pressure in the fermenter to 0.09-0.10MPa, keep the temperature at 1...

Embodiment 2

[0039] A sweet corn whole milk lactic acid bacteria beverage is prepared through the following steps:

[0040] (1) Washing the fresh sweet corn, threshing, and discarding the corn cob to obtain fresh corn kernels;

[0041] (2) Add fresh corn kernels and purified water into a colloid mill at a mass ratio of 1:1, and crush and homogenize to obtain fresh corn steep liquor;

[0042] (3) Add an appropriate amount of water into the fermenter, and mix fresh corn steep liquor, brown sugar, glucose, whey powder, and K 2 HPO 4 、KH 2 PO 4 , MgSO 4 Add it into the tank, stir to dissolve and then constant volume to obtain a fermentation medium, in which the final mass-volume ratio of each component is: fresh corn steep liquor 50%, brown sugar 2%, glucose 3%, whey powder 0.05%, K 2 HPO 4 0.01%, KH 2 PO 4 0.04%, MgSO 4 0.05%; the initial pH value of the medium is 5.5-6.5; use high-temperature steam to control the pressure in the fermenter to 0.09-0.10MPa, keep the temperature at 1...

Embodiment 3

[0046] A sweet corn whole milk lactic acid bacteria beverage is prepared through the following steps:

[0047] (1) Washing the fresh sweet corn, threshing, and discarding the corn cob to obtain fresh corn kernels;

[0048] (2) Add fresh corn kernels and purified water into a colloid mill at a mass ratio of 1:1, and crush and homogenize to obtain fresh corn steep liquor;

[0049] (3) Add an appropriate amount of water into the fermenter, and mix fresh corn steep liquor, brown sugar, glucose, whey powder, and K 2 HPO 4 、KH 2 PO 4 , MgSO 4 Add it into the tank, stir to dissolve and then constant volume to obtain a fermentation medium, in which the final mass-volume ratio of each component is: fresh corn steep liquor 25%, brown sugar 4%, glucose 2.5%, whey powder 0.05%, K 2 HPO 4 0.01%, KH 2 PO 4 0.04%, MgSO 4 0.03%; the initial pH value of the medium is 5.5-6.5; use high-temperature steam to control the pressure in the fermenter to 0.09-0.10MPa, keep the temperature at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com