Tea leaf-sourced plant soft capsule shell and application and preparation method of tea leaf-sourced plant soft capsule

A soft capsule shell and soft capsule technology, which are applied in the directions of capsule delivery, cosmetic preparations, skin care preparations, etc., can solve the problems of easy leakage of gelatin capsule shells, adhesion and cross-linking reactions, and high pollution risks, so as to overcome the product Defects, not easy to deform and stick, overcome the effect of easy leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

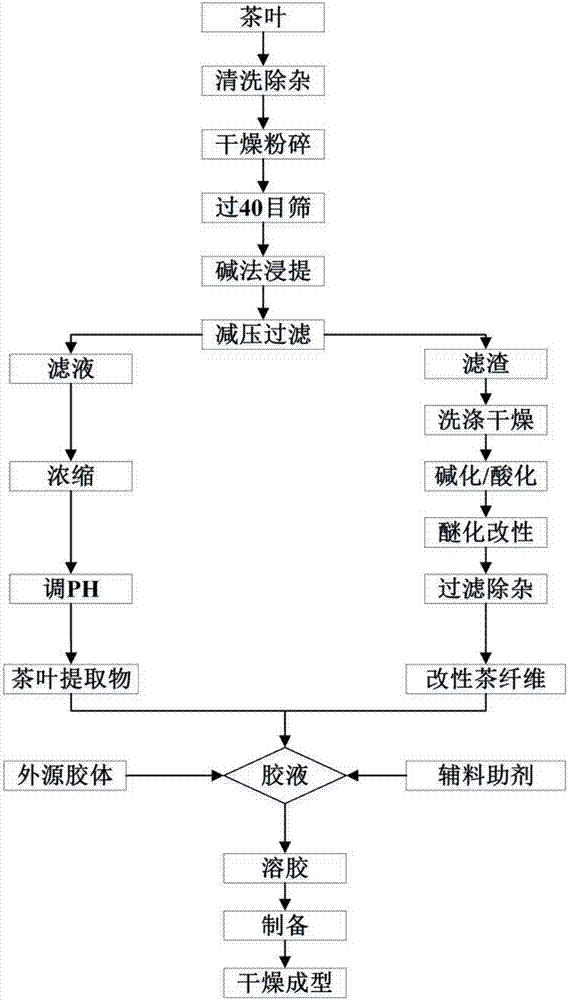

[0030] refer to figure 1 , the preparation method of a kind of tea plant soft capsule of the embodiment of the present invention, comprises following main steps successively:

[0031]a) Preparation of tea extract: the picked tea leaves are washed, dried, crushed, and passed through a 40-mesh sieve to obtain tea powder. The tea powder is mixed with 0.06mol / L sodium hydroxide at 1:40 (w / v, g / ml) Mix the solution evenly, that is, add 40 ml of 0.06mol / L sodium hydroxide solution for every 1 gram of tea powder; extract in a water bath at 90-100°C for 60 minutes, shake the extract once every 5 minutes; filter and concentrate the obtained concentrate after extracting in a water bath Hydrochloric acid was adjusted to pH=5.8 to obtain tea extract.

[0032] b) Preparation of modified tea fiber: take 5g of tea dregs washed to neutrality and dried by hot air in a three-necked flask with a stirring device, add 50ml of 75% ethanol, 50ml of 20% NaOH solution, and alkalinize at 30°C. The al...

Embodiment 2

[0036] In the embodiment of the present invention, the tea dregs after tea extraction are treated with enzymatic hydrolysis, and the rest of the preparation method is basically the same as in embodiment 1, the difference is:

[0037] a) Tea dregs enzymatic hydrolysis: mix 20% NaOH (or 2% dilute sulfuric acid solution) solution with tea dregs washed to neutral and dried at 10:1, (10 mL of liquid corresponds to 1 g of solid) in a water bath at 120 ° C After boiling for 30 minutes, filter and wash with water until neutral. Add 2g of tea residue fiber washed to neutrality and 100U of cellulase into a 250ml Erlenmeyer flask with a stopper, then add 100ml of 0.2mol / L HAc-NaAc buffer solution with a pH value of 4.8, place it in a constant temperature shaker Reactor at 50°C for 24-48h. After the enzymatic hydrolysis is completed, the tea dregs are removed by filtration, and the enzymatic hydrolysis solution is incorporated into the tea extract to prepare the next glue solution.

[0...

Embodiment 3

[0040] The method of enzymatic hydrolysis of the tea residue fiber is different for the soft capsules described in the examples of the present invention, and the other preparation processes are basically the same as in Example 2. In this embodiment, the cellulase for enzymatically hydrolyzing tea dregs is adjusted to one or more of the polygalacturonase, β-glucosidase, pectinase, protease and other multi-enzyme systems acting synergistically.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com