Preparation method of hydrophobic lipophilic high-molecular composite microspheres

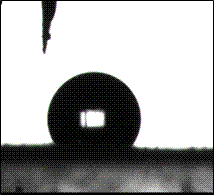

A polymer microsphere, hydrophobic and lipophilic technology, which is applied in the field of preparation of hydrophobic and lipophilic polymer composite microspheres, can solve the problems of difficult-to-use microsphere products on an industrial scale, poor dispersibility, and interface bonding degree of agglomeration of microspheres, etc. The effect of good application prospect, simple process and good application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

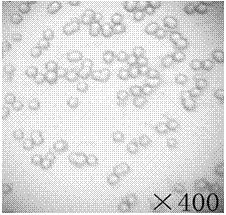

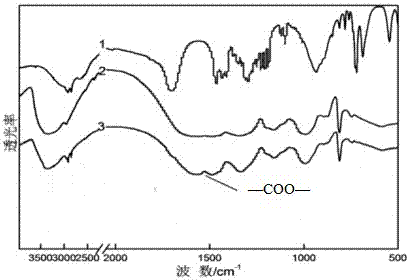

[0026] (1) Weigh 5.4g of fresh wet melamine resin thermosetting polymer microspheres (60% solid content) prepared by dispersion polymerization as cue balls, add 100mL water and ultrasonically disperse for 60 minutes to obtain uniformly dispersed microspheres mixture.

[0027] (2) Prepare 300mL of water / ethanol (mass ratio: 1:1) solution, add 0.0540g of dodecanoic acid to form a modified solvent;

[0028] (3) Add the uniformly dispersed microsphere mixture in step (1) to the modified solvent prepared in step (2), stir well to disperse evenly, heat up to 70 degrees Celsius, react for 60 minutes, settle and separate, and dry the obtained surface Hydrophobic and lipophilic melamine resin polymer composite microspheres.

Embodiment 2

[0030] (1) Weigh 5.4 g of fresh wet phenolic thermosetting polymer microspheres (50% solid content) prepared by dispersion polymerization as cue balls, add 150 mL of water and ultrasonically disperse for 30 minutes to obtain a uniformly dispersed microsphere mixture.

[0031] (2) Prepare 300mL of water / ethanol (mass ratio: 1:1) solution, add 0.1620g of dodecanoic acid to form a modified solvent;

[0032] (3) Add the uniformly dispersed microsphere mixture in step (1) to the modified solvent prepared in step (2), stir well to disperse evenly, heat up to 80 degrees Celsius, react for 60 minutes, settle and separate, and dry the obtained surface Hydrophobic and lipophilic phenolic polymer composite microspheres.

Embodiment 3

[0034] (1) Weigh 1.5g of fresh wet urea-formaldehyde thermosetting polymer microspheres (60% solid content) prepared by dispersion polymerization and 3.0g of fresh wet phenolic resin thermosetting polymers prepared by dispersion polymerization Microspheres (50% solid content) are cue balls, and 120 mL of water is added for ultrasonic dispersion for 45 minutes to obtain a uniformly dispersed microsphere mixture.

[0035] (2) Prepare 400mL of water / ethanol (mass ratio: 1:1) solution, add 0.1620g of myristic acid to form a modified solvent;

[0036] (3) Add the uniformly dispersed microsphere mixture in step (1) to the modified solvent prepared in step (2), stir well to disperse evenly, heat up to 60 degrees Celsius, react for 30 minutes, settle and separate, and dry the obtained surface Hydrophobic and lipophilic urea-formaldehyde polymer composite microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com